Non-tracking solar compound paraboloid condenser

A compound paraboloid and concentrator technology, applied in the field of solar energy applications, can solve the problems of slow commercialization, poor concentrating effect, and poor availability, and achieve good heat utilization effect, simple generation method, and low application cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Application requirements: first, it is completely fixed and free from tracking, second, it is placed on a flat roof, and third, the application site is 30.0 degrees north latitude, and it requires integrated installation with the roof.

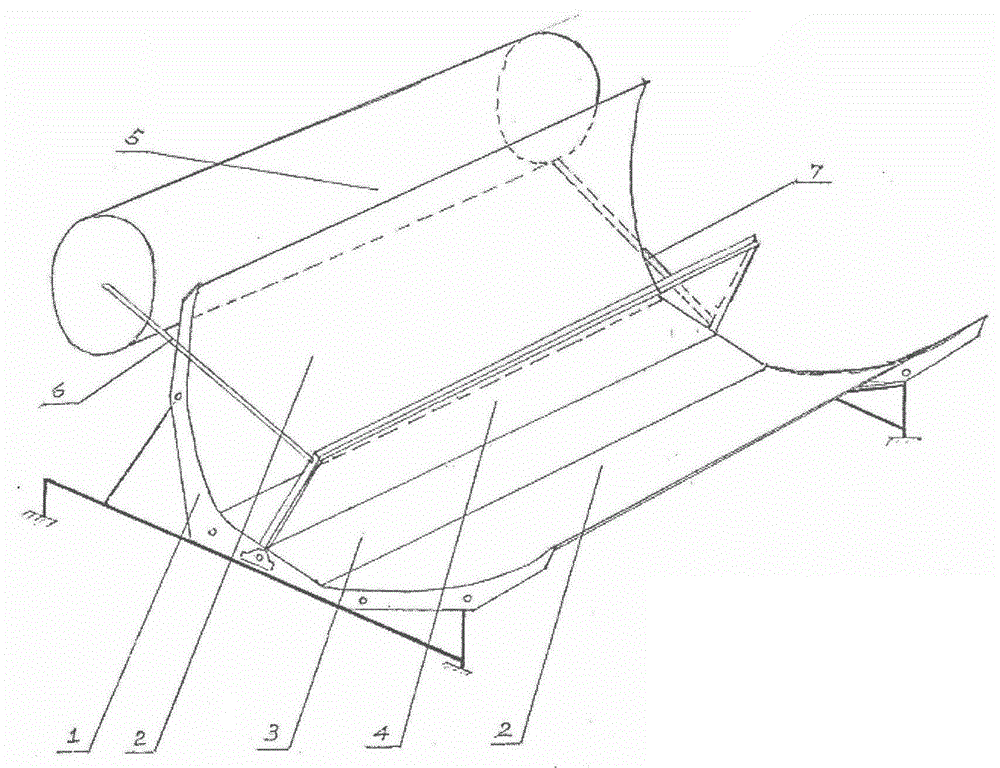

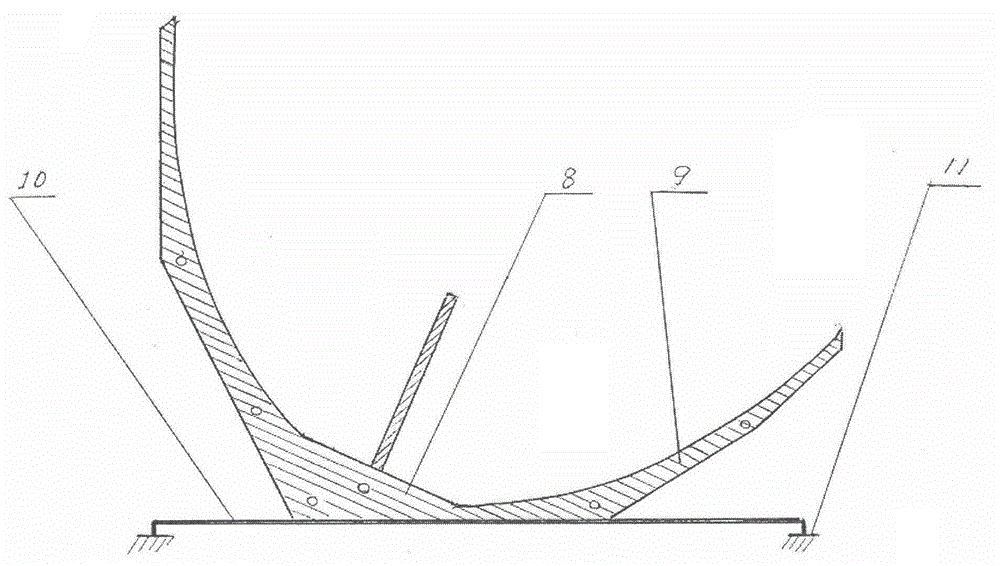

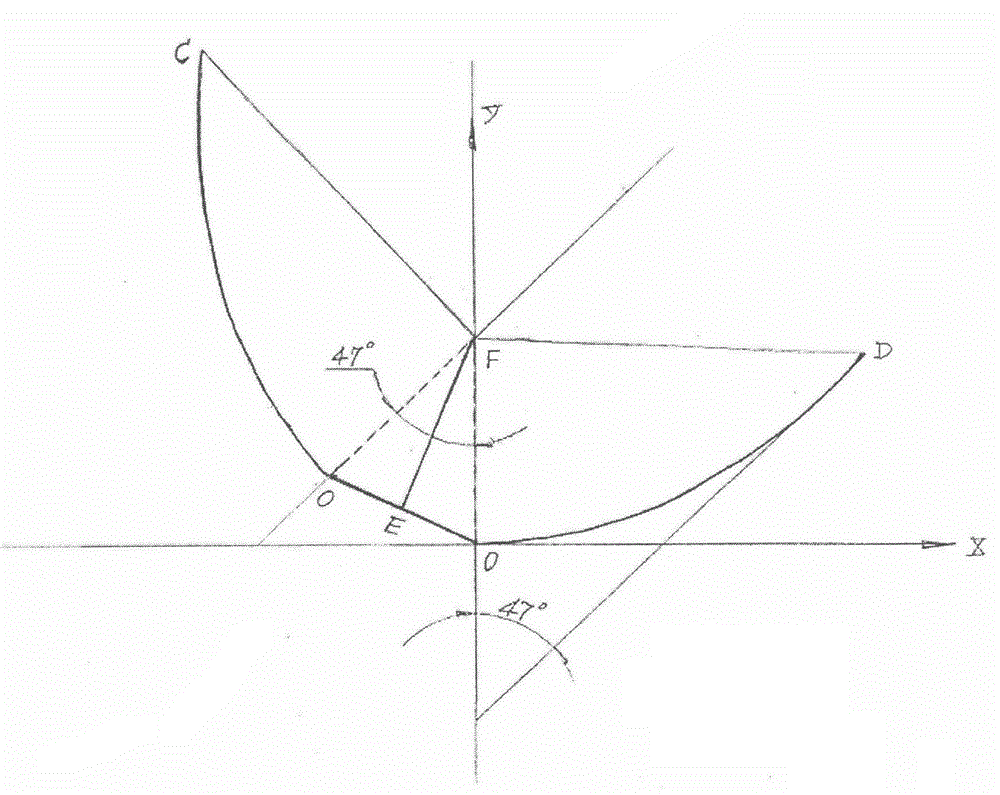

[0033] see figure 1 , 2 , 3 a kind of tracking-free solar compound parabolic concentrator, its compound parabolic mirror surface is compounded and generated by the parabolic light-concentrating curve, according to Y=X2 / 4F parabolic equation, make the parabolic curve coordinate figure that is 50cm with the focal length, in the parabolic curve On the coordinate diagram, according to the fact that the tracking-free solar compound parabolic concentrator is completely fixed as a fixed point, the intercepted half parabola segment located in the 1 image area is rotated clockwise until the angle between its focal line and the Y axis is equal to 47° , move the generated composite parabolic concentrating curve section along the vertical directi...

Embodiment 2

[0035] Application requirements: First, it is completely fixed and free from tracking. The second is that the placement site is a sunny slope roof with a slope of 40°. The third is that the application site is 30° north latitude, and the fourth is that in order not to affect the architectural landscape, the thickness of the generated concentrator shall not exceed 20cm. Under the condition of being completely fixed and tracking-free, it is guaranteed to receive incident sunlight throughout the year.

[0036] see Figure 4 A kind of tracking-free solar compound parabolic concentrator, its compound parabolic reflector surface is generated by compounding the parabolic concentration curve, the generation method is: according to Y=X2 / 4F parabolic equation, make the parabolic curve coordinate map that is 7cm with focal length, in On the parabolic curve coordinate diagram, according to the requirement that the tracking-free solar compound parabolic concentrator is completely fixed, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com