Vapor-liquid sensor

A sensor and gas-liquid technology, applied in the field of sensors, can solve the problems of easy sticking of the floating ball on the guide rod, failure of the gas-liquid sensor, and low detection sensitivity, and achieve the effects of light weight, good sealing, and high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

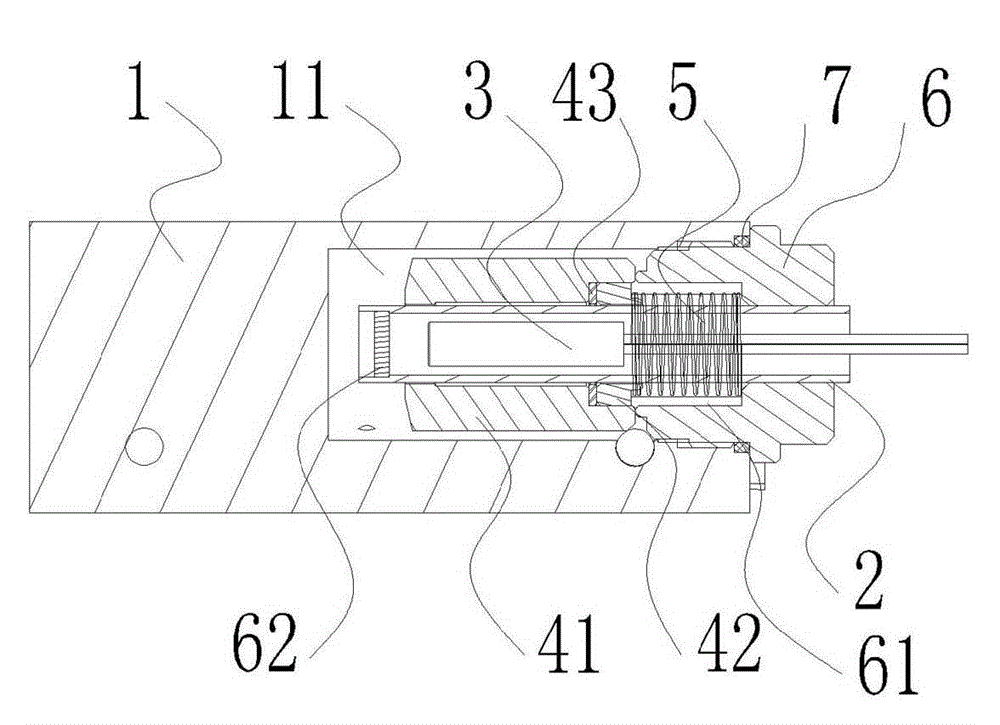

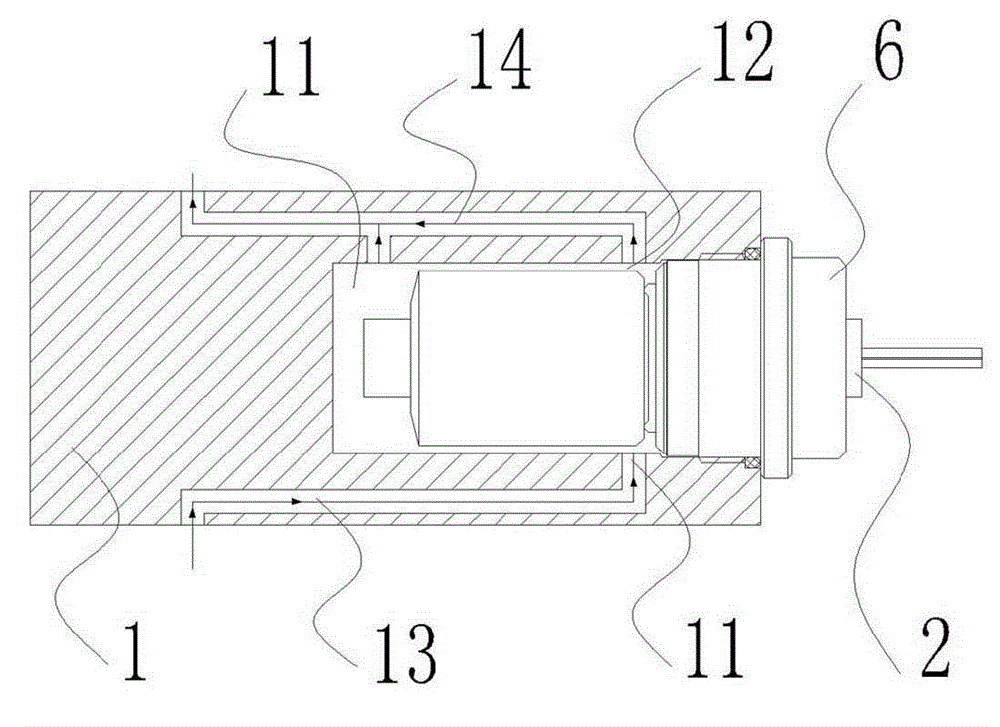

[0016] Such as figure 1 As shown, a gas-liquid sensor of the present invention includes a rectangular parallelepiped valve body 1, one end of the valve body 1 extends inwardly to form a cylindrical accommodation chamber 11, and a guide is screwed to the opening of the accommodation chamber 11. Rod joint 6, and an O-ring 7 is installed between the valve body 1 and the opposite end surface of the guide rod joint 6, a hollow guide rod 2 is inserted in the middle of the guide rod joint 6, and the outer ring surface of the hollow guide rod 2 The seal is welded on the guide rod joint 6, and the inner end of the hollow guide rod 2 extends into the accommodation cavity 11, the hollow guide rod 2 is made of copper tube, and a guide rod plug 62 is screwed on the inner end of the copper tube, A magnetic switch 3 is fixed in the cavity of the hollow guide rod 2, the wire on the magnetic switch 3 extends outward from the outer end opening of the copper tube, and a floating ball is slid out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com