System and method for calibrating optical axis of non-spherical reflecting mirror

A mirror and aspheric surface technology, which is applied in the field of optical assembly and inspection, can solve the problems of increasing the difficulty of the optical axis, and achieve the effect of reducing the risk of mirror surface scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

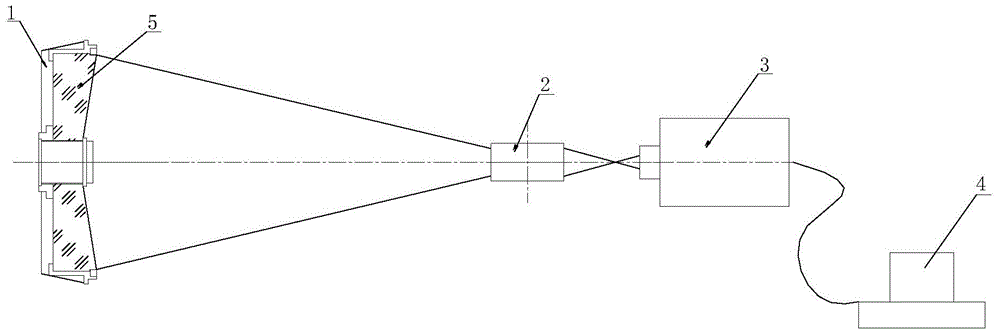

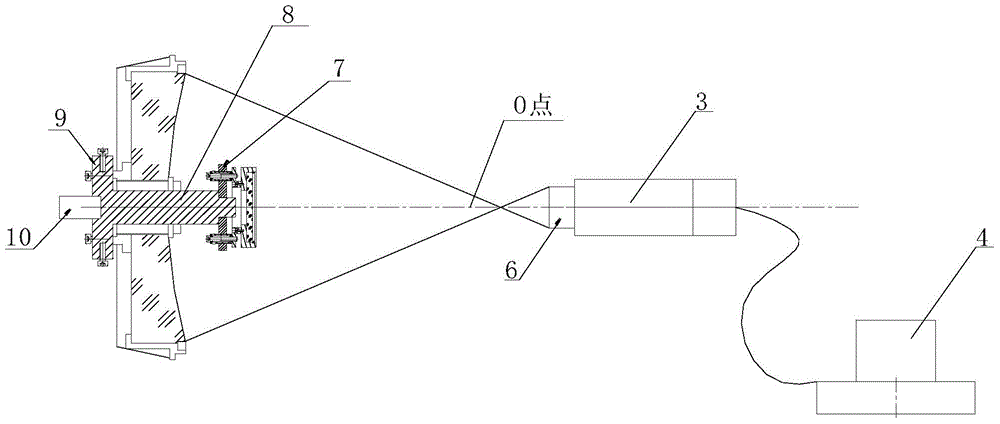

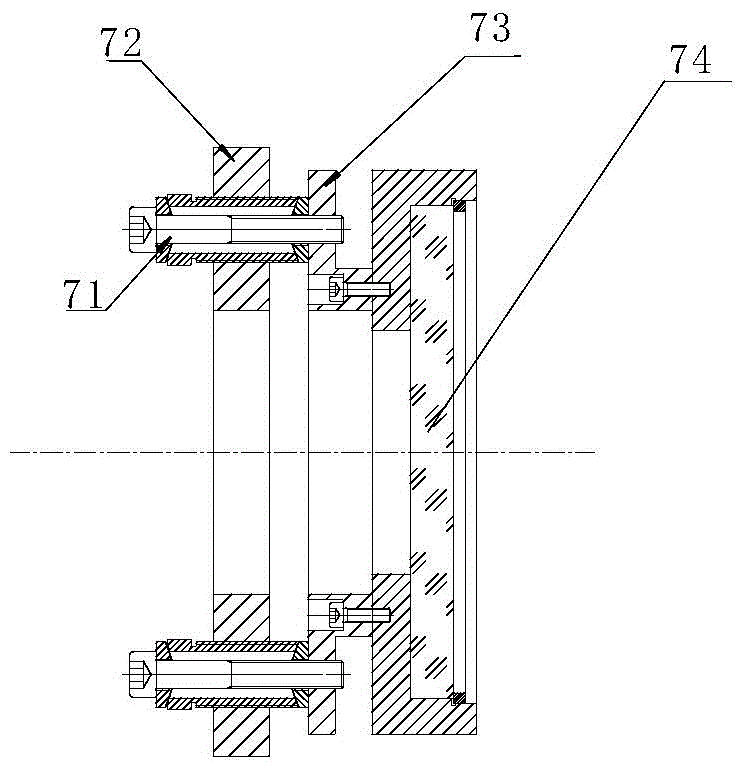

[0030] A system for calibrating the optical axis of an aspheric mirror, including the first optical path, the second optical path and the third optical path, such as Figure 1-5 As shown, the first optical path includes a frame 1, a compensator 2, a laser interferometer 3 and a PC 4 placed in sequence, an aspheric reflector 5 is fixed on the frame 1, and the aspheric reflector, compensator, and laser interferometer The optical axis is coaxial, one end of the laser interferometer is the lens and faces the aspheric reflector, the other end of the laser interferometer is connected to the PC, the lens is a spherical standard lens and matches the R / D value of the aspheric reflector, where R is the radius of the aspheric mirror, D is the diameter of the aspheric mirror;

[0031] The structure of the second optical path is: remove the compensator in the first optical path, replace the lens of the laser interferometer 3 in the first optical path with a flat standard lens, install and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com