Involute internal gear generating instrument

A technology of internal gear and involute, which is applied in the field of involute internal gear fan forming instrument, to achieve the effect of convenient operation and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

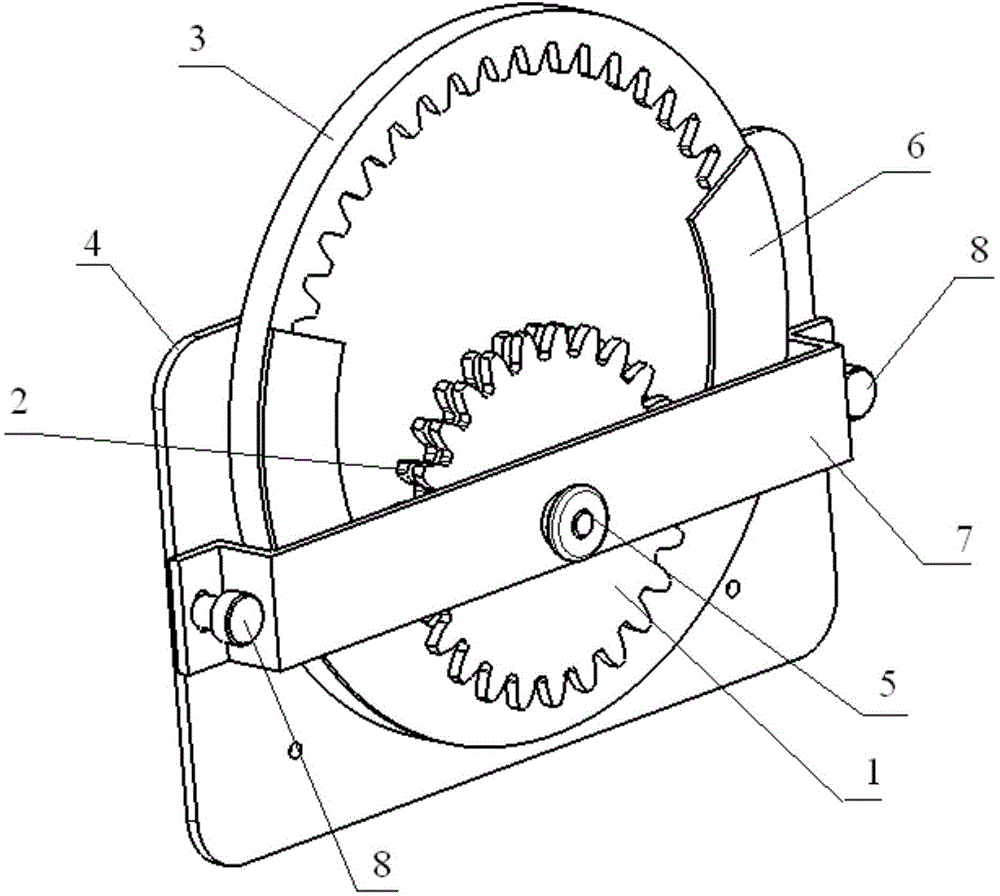

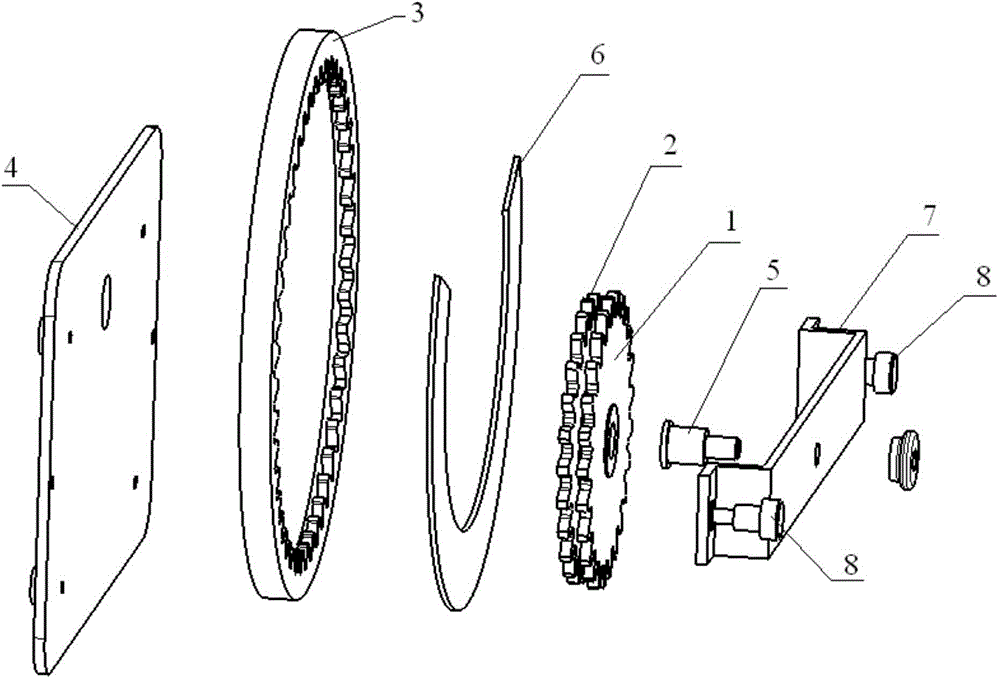

[0016] see figure 1 and figure 2 Shown:

[0017] The involute internal gear fan provided by the present invention includes a first external gear 1, a second external gear 2, an internal gear 3 and a bottom plate 4, wherein the first external gear 1 and the second external gear 2 are coaxially connected by a fixed shaft 5 , synchronous rotation, the second external gear 2 meshes with the internal gear 3, the second external gear 2 drives the internal gear 3 to rotate synchronously with the first external gear 1, and the internal gear 3 is pivotally connected to the bottom plate 4.

[0018] A backing plate 6 is sandwiched between the first external gear 1 and the second external gear 2 , the backing plate 6 is connected to the internal gear 3 , and the backing plate 6 and the internal gear 3 rotate synchronously.

[0019] The first external gear 1 and the second external gear 2 are fixed on the bottom plate 4 through the frame body 7, and the position of the frame body 7 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com