Fire resisting damper used for treating paint mist

A fire damper and paint mist technology, which is applied in the spray booth, the device for coating liquid on the surface, the injection device, etc., can solve the problems that the fire in the equipment warehouse cannot be controlled and the fire in the equipment warehouse can not be controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

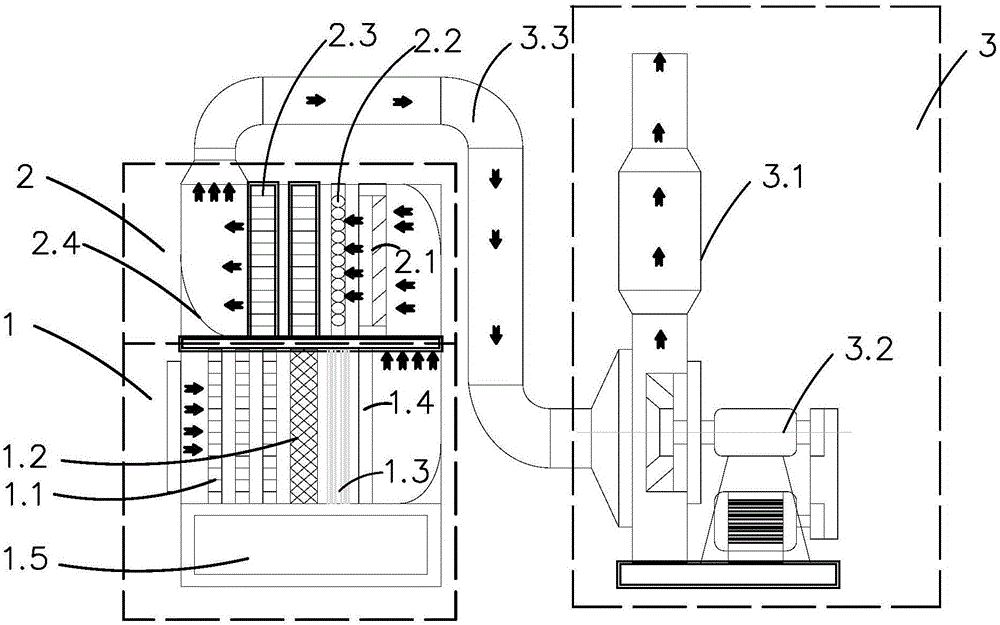

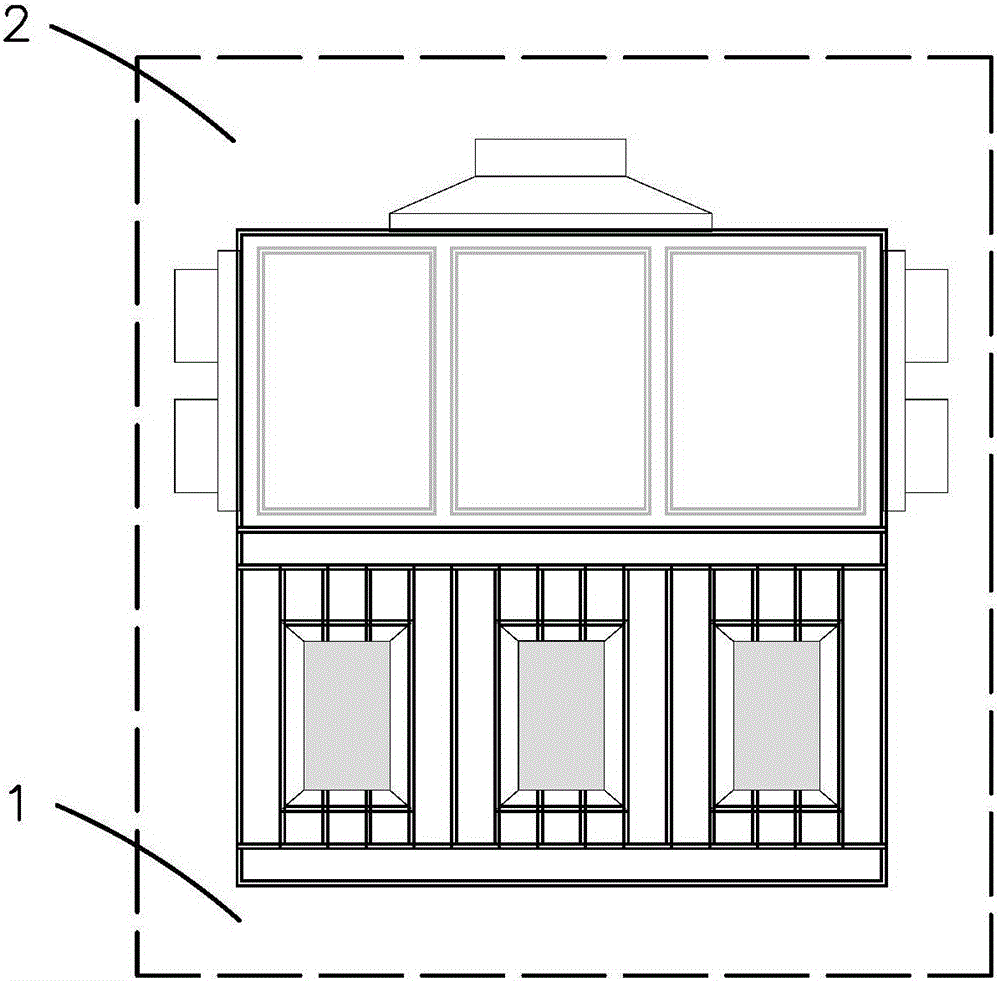

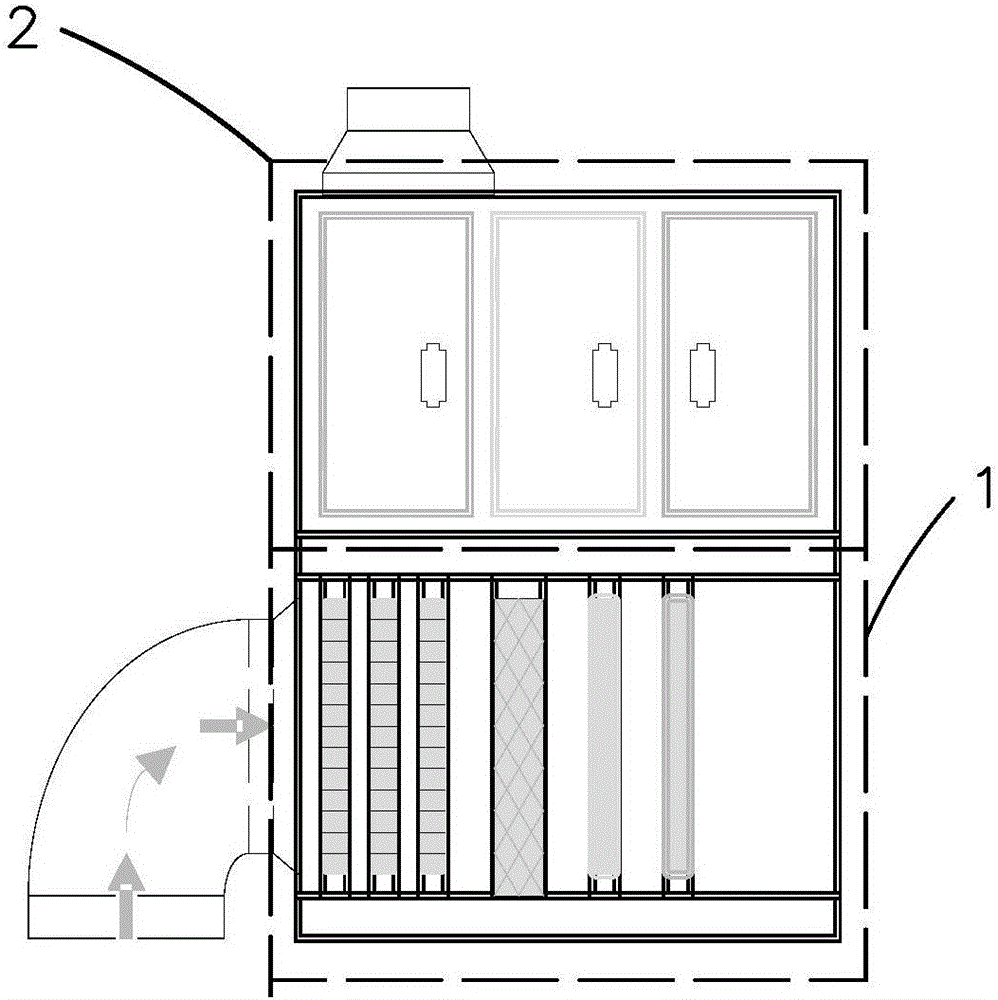

[0059] The paint mist treatment equipment provided in the present invention includes three paint mist treatment stages.

[0060] The first treatment stage: inside the paint mist catalytic chamber 1 in the water curtain spray booth, the interior of the catalytic chamber 1 is provided with a filter 1.1, a wet filter 1.2, a dehydrator 1.3 and an activated carbon filter bag 1.4 in sequence along the airflow; the paint mist passes through first. The filter 1.1 is used for filtering, and the airflow passes through the space between the Venturi filter tube 1.1.2 and the casing 1.1.4 to form a space that can accommodate the paint mist, and the filtered paint mist forms a spiral in the space to precipitate a part of impurities. The preferred filter housing 1.1.4 can be stacked in two layers, and a two-layer space that can accommodate paint mist is formed between the two layers of Venturi filter tubes 1.1.2 and the two layers of housing 1.1.4, which can separate impurities from the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com