Material classification screening method and device

A material classification and equipment technology, applied in chemical instruments and methods, filtration, solid separation, etc., can solve problems such as inability to separate materials, unfavorable environmental protection, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

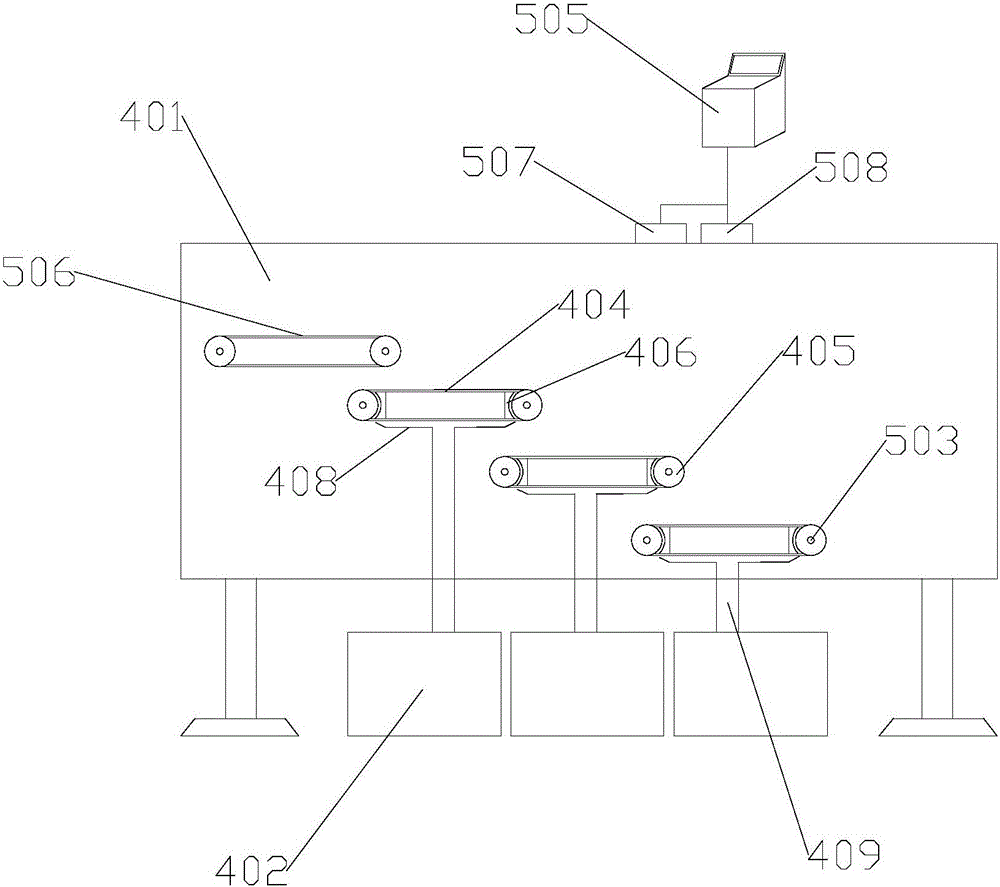

[0052] Embodiment 1, with reference to Figure 1 to Figure 2 .

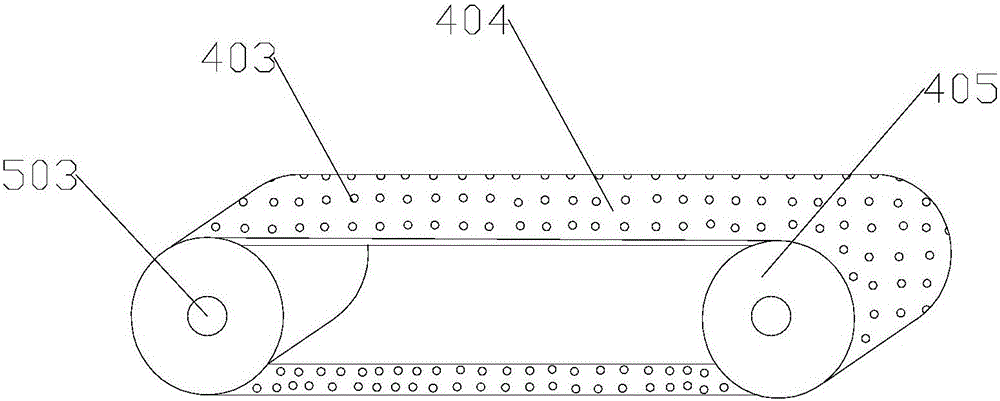

[0053] A kind of equipment that is used to realize the method for material graded screening, comprises frame 401, vibration screening device and storage device, and vibration screening device is arranged on frame 401, and storage device comprises a plurality of material storage chambers 402; Vibration screening device comprises at least Three vibrating screening parts, each vibrating screening part is provided with a leaking screen hole 403, the diameter of the leaking screen hole 403 on the vibrating screening part is smaller than the diameter of the leaking screen hole 403 on the next vibrating screening part, each vibrating screening A material storage chamber 402 is provided below each part.

[0054] Each vibrating screening part is provided with leaking screen holes 403, and the leaking screen holes 403 on each vibrating screening part are equal in size, and the leaking screen holes 403 are different betwee...

Embodiment 2

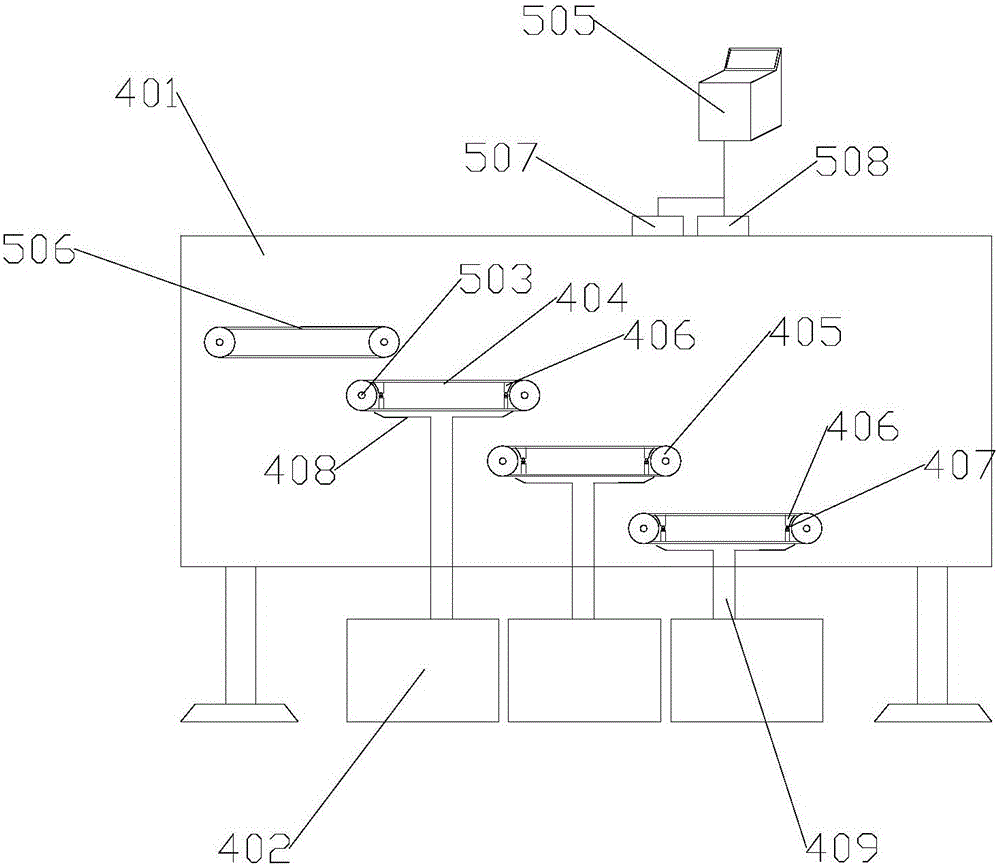

[0061] Embodiment 2, with reference to Figure 3 to Figure 8 .

[0062] In this embodiment, the vibration mechanism also includes a plurality of cam mechanisms, the cam mechanism includes a cam 407, and each vibration baffle plate 406 is divided into two parts vertically arranged, which are respectively an upper half and a lower half, and the upper half and the lower half. The lower half is slidably embedded on the frame 401 respectively, the side of the upper half near the driving wheel 405 is an arc surface, the side of the lower half near the driving wheel 405 is a plane, and the cam 407 is arranged on the top of the baffle. between half and bottom half.

[0063] In the process of the vibration baffle 406 moving up and down, in order to ensure that the material will not fall into the gap formed between the transmission wheel 405 and the screening conveyor belt 404, the upper half of the vibration baffle 406 is designed near the side of the transmission wheel 405 as The cu...

Embodiment 3

[0070] Embodiment 3, with reference to Figure 9 to Figure 12 .

[0071] In this embodiment, the vibrating screening device is a vibrating screen 504, and the vibrating screen 504 includes one sieve plate provided with multiple vibrating screening parts or multiple sieve plates provided with one vibrating screening part respectively.

[0072] In addition to the screening conveyor belt 404, the vibratory screening device can also use a vibrating screen 504, a sieve plate can be used, and a plurality of vibrating screening parts can be used on the sieve plate, or a plurality of sieve plates can be used, and each sieve plate is separately Vibration screening parts are provided, of course, the size of the leaking screen holes 403 on one vibration screening part is still the same, and the size of the leaking screen holes 403 between each vibration screening part is different. Smaller than the drain screen hole 403 on the rear vibrating screen section. When the vibrating screen 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com