Panel groove fast molding device and method

A technology of forming device and plate, applied in the direction of forming tools for metal extrusion, metal extrusion, metal processing equipment, etc., to achieve the effect of improving processing efficiency, avoiding displacement and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0040] The invention also discloses a method for rapid forming of plate grooves, which includes the following steps:

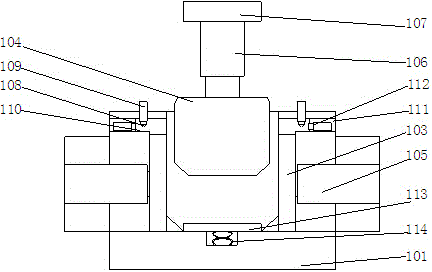

[0041] S1: The plate to be processed is embedded in the T-shaped groove 111 provided on the fixed bracket 101, so that the plate slides into the limit groove 110 through the T-shaped groove, and the two ends of the plate are clamped in the limit groove 110, so that the adjustment hydraulic cylinder 112 telescopic rods are pressed against both sides of the plate;

[0042] S2: Start and adjust the hydraulic cylinder 112 to push the horizontal position of the plate, so that the plate is located directly below the longitudinal forming platen 104, start the fastening cylinder 109, and press the tapered end of the conical top pressure block 108 on the lower part of the fastening cylinder 109 against the plate upper surface;

[0043] S3: Start the longitudinal hydraulic cylinder 106, make the telescopic rod of the longitudinal hydraulic cylinder 106 push the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com