Automatic dust falling sheet metal maintenance platform

A maintenance station and dust reduction technology, which is applied in the field of sheet metal maintenance stations, can solve the problems of hidden dangers of operators, iron filings and dust scattering, and achieve the effects of reducing the amount of iron filings and dust, improving air quality, and reducing the degree of occupational disease hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

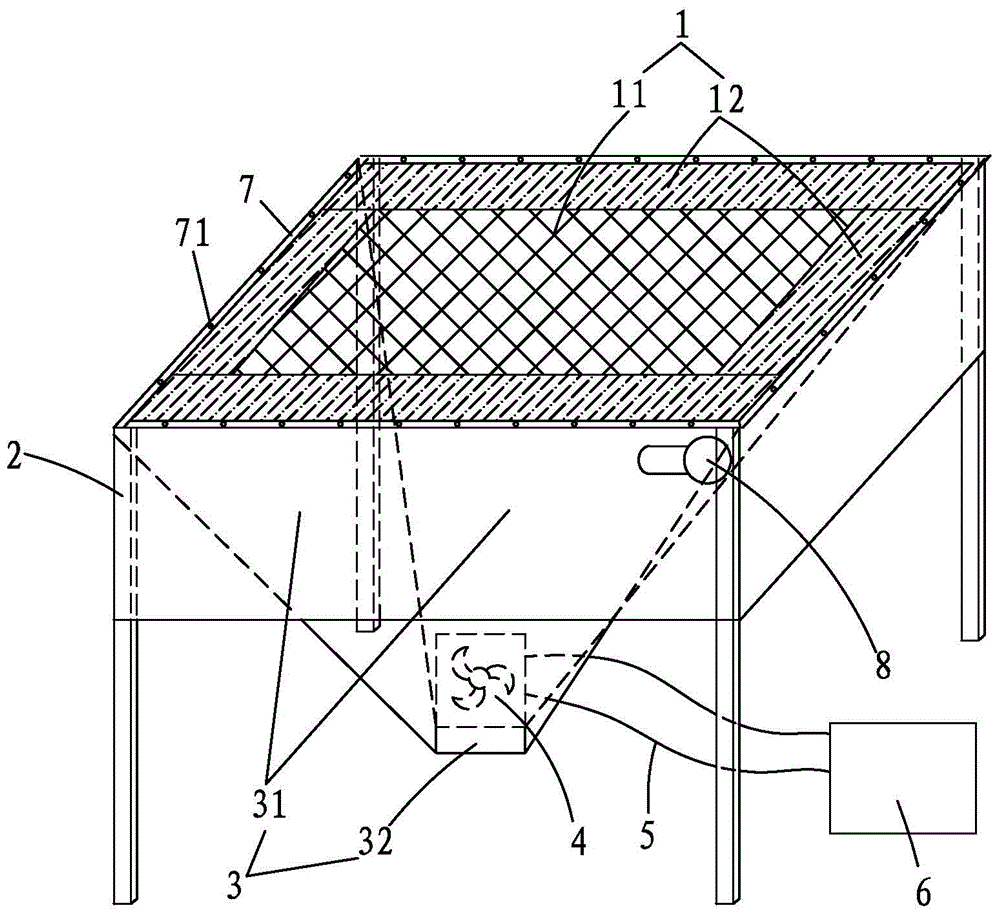

[0014] see figure 1 , an automatic dust-reducing sheet metal maintenance platform of the present invention, comprising a table top 1, a fixed frame 2 and a dust-removing tank 3, the table top 1 includes a hollowed iron grid 11 and artificial wires laid on the edge of the upper surface of the hollowed iron grid 11 for a week The turf strip 12, the hollow iron grid 11 is supported by the fixed frame 2, the dust removal tank 3 is located below the hollow iron grid 11, the bottom of the dust removal tank 3 is provided with an exhaust fan 4, and the exhaust fan 4 passes through a pipe 5 Connected with a collection box 6, the maintenance station also includes a blowing pipe 7 and a blowing gas source switch 8 for controlling the blowing pipe 7, the blowing gas source switch 8 is installed on the fixed frame 2, and the blowing pipe 7 is set around the upper edge of the dust removal tank 3, and a plurality of exhaust holes 71 are set at intervals on the blowing pipe 7, and the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com