Novel tire and preparation method thereof

A new tire and carcass technology, which is applied to tire parts, reinforcing layers of pneumatic tires, tires, etc., can solve the problems of cumbersome pattern mold replacement, slow pattern update speed, delayed delivery, etc., to achieve rich tire pattern styles, The effect of improving the unevenness of vulcanization and improving the overall life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

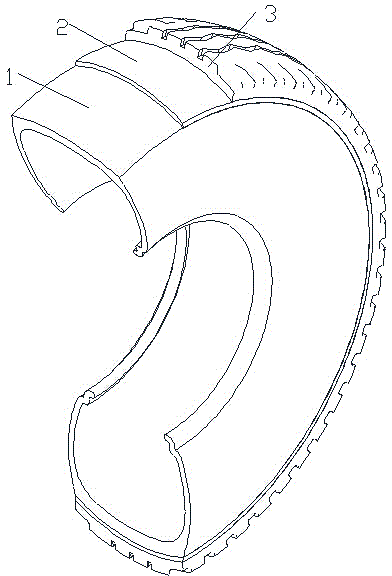

[0028] The new tire of the present invention is as figure 1 As shown, it includes a precured carcass 1, a mid cushion rubber 2 and a precured tread rubber 3. The middle pad rubber 2 is arranged between the pre-vulcanized carcass 1 and the pre-vulcanized tread rubber 3, and the three are bonded and vulcanized together (bonded together). The middle cushion rubber 2 is initially unvulcanized rubber, and after being vulcanized, the middle cushion rubber 2 is vulcanized together with the precured carcass 1 and the precured tread rubber 3 to form a new tire.

[0029] The pre-vulcanized carcass 1 refers to a new carcass that has been vulcanized in advance and has no crown pattern and has not been used. The pre-vulcanized tread rubber 3 refers to the tread rubber that has been vulcanized in advance. The surface of the pre-vulcanized tread rubber 3 that is bonded to the middle cushion rubber 2 is called the tread rubber bonding surface. The bonding surface of the tread rubber is pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com