Material transfer device based on composite planetary gear mechanism

A technology of compound planetary gear and transfer device, which is applied in the direction of conveyor objects, transportation and packaging, etc., to achieve the effect of large transfer range, enlarged transfer stroke and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

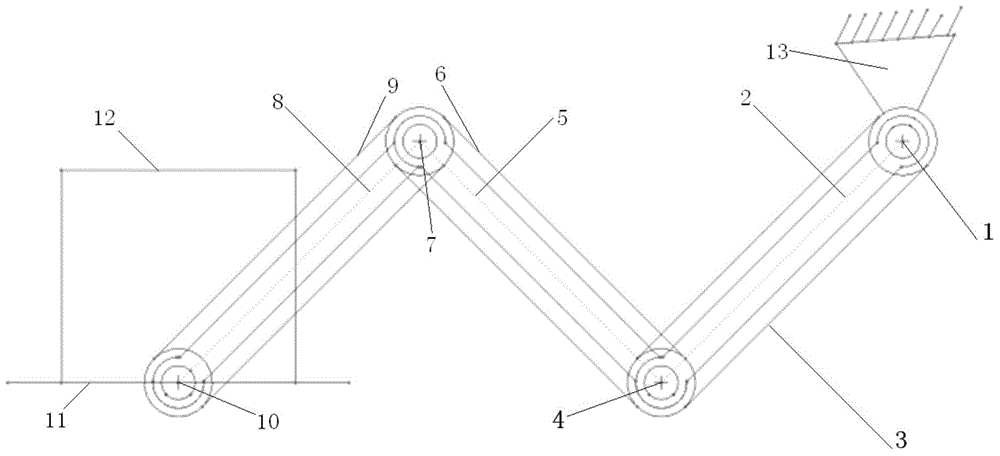

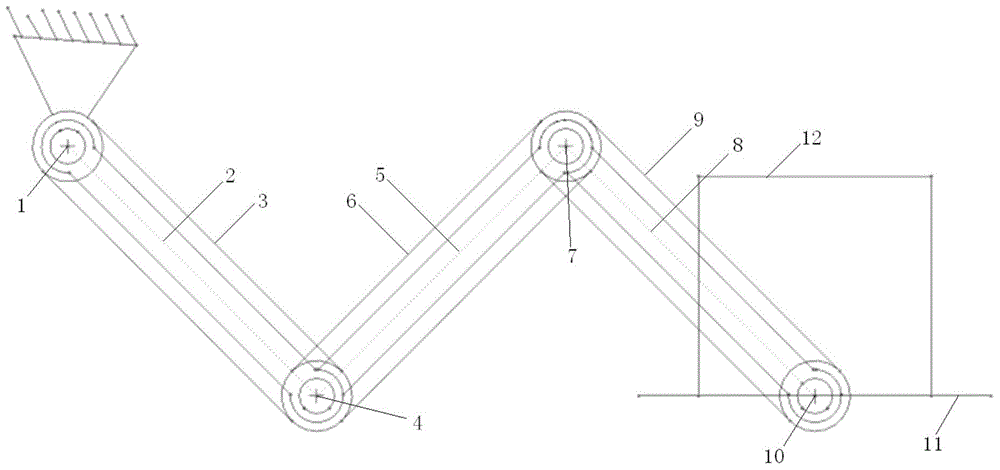

[0024] see Figure 1-3 , a material transfer device based on a composite planetary gear mechanism, including a driving device, a support 13, a fixed wheel 1, a connecting body I2, a grommet I3, a composite wheel I4, a composite wheel assembly, a grommet X9, a connecting body X8, a rotating Wheel 10 and pallet 11, wherein,

[0025] The fixed wheel 1 is fixedly connected to the support 13, the fixed wheel 1 cannot rotate, and the two ends of the connecting body I2 are respectively rotatably connected to the fixed wheel 1 and the composite wheel I4, and the connection The body I2 can rotate relative to the fixed wheel 1 and the composite wheel I4, the grommet I3 goes around the fixed wheel 1 and the composite wheel I4, and the connecting body I2 swings around the fixed wheel 1 The compound wheel I4 can be driven to rotate through the grommet I3;

[0026] The composite wheel assembly includes connector II5, grommet II6 and composite wheel II7, the two ends of the connector II5 a...

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is that the fixed wheel 1, the composite wheel I4, the composite wheel II7 and the rotating wheel 10 are all sprockets, and the grommets I3, grommets II6 and grommets X9 are all chains. Other structures and principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

[0036] In this embodiment, the fixed wheel 1, composite wheel I4, composite wheel II7 and rotating wheel 10 are set as sprockets, and the grommet I3, grommet II6 and grommet X9 are set as chains to increase the load capacity of the material transfer device ability.

[0037] The working process of the material transfer device of the present invention is described below.

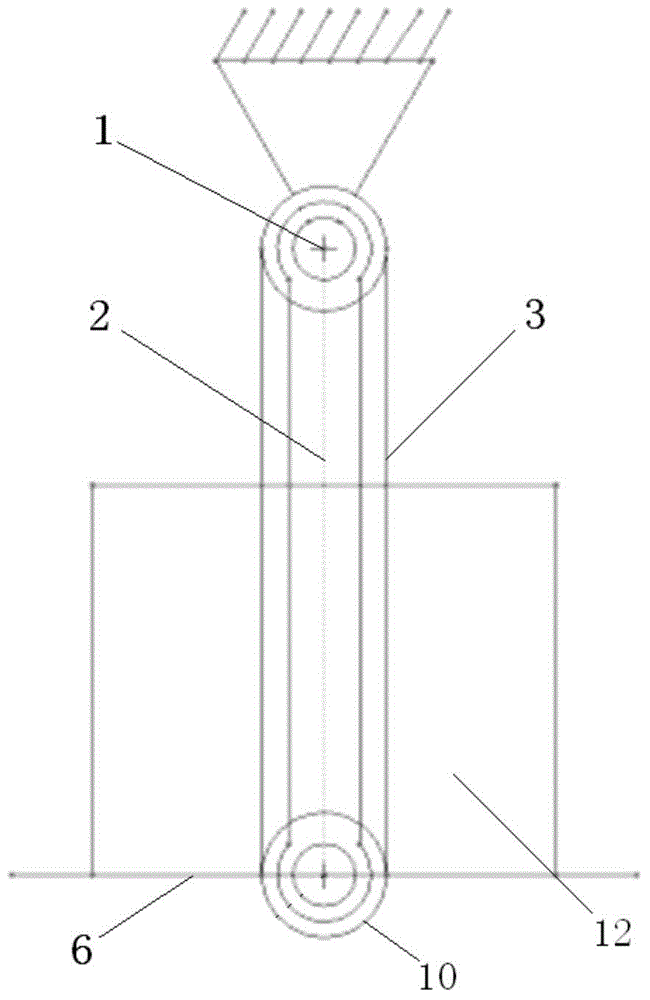

[0038] The fixed wheel 1 is fixedly connected on the support 13, and the material 12 to be transferred is placed on the pallet 11, as figure 2 As shown, the connecting body I2 is driven by the motor or motor to swing to the left, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com