Electric energy meter robot feeding and discharging system and working process thereof

A technology of electric energy meters and robots, which is applied in the field of electric energy meter robot loading and unloading systems and their work processes, can solve the problems of high labor intensity, high labor costs, and low work efficiency in manual operations, and achieve high production efficiency and high degree of automation , the effect of improving precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

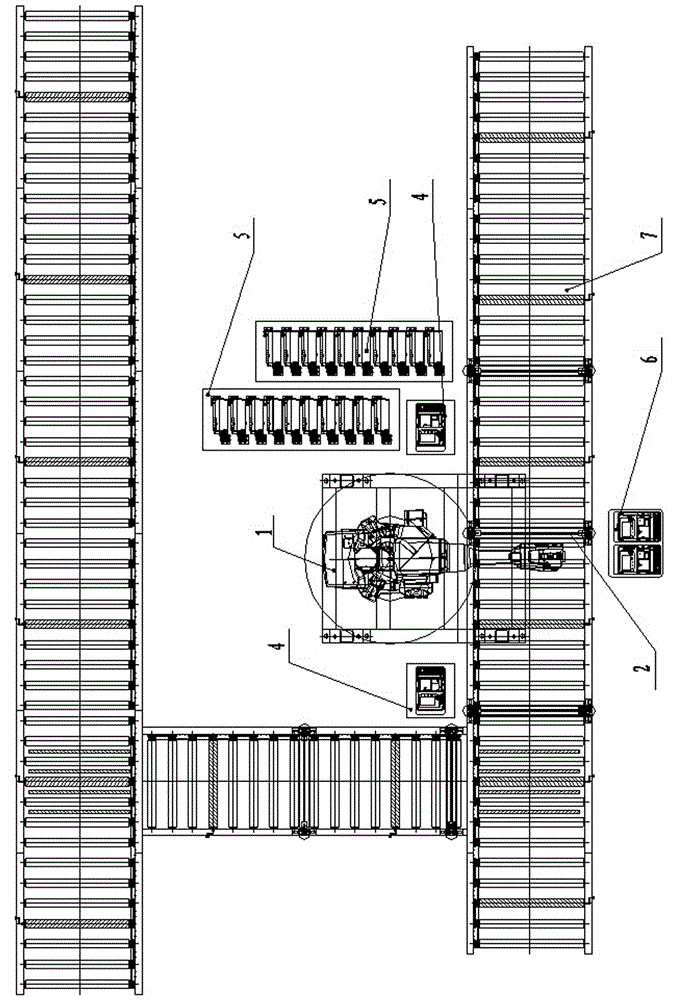

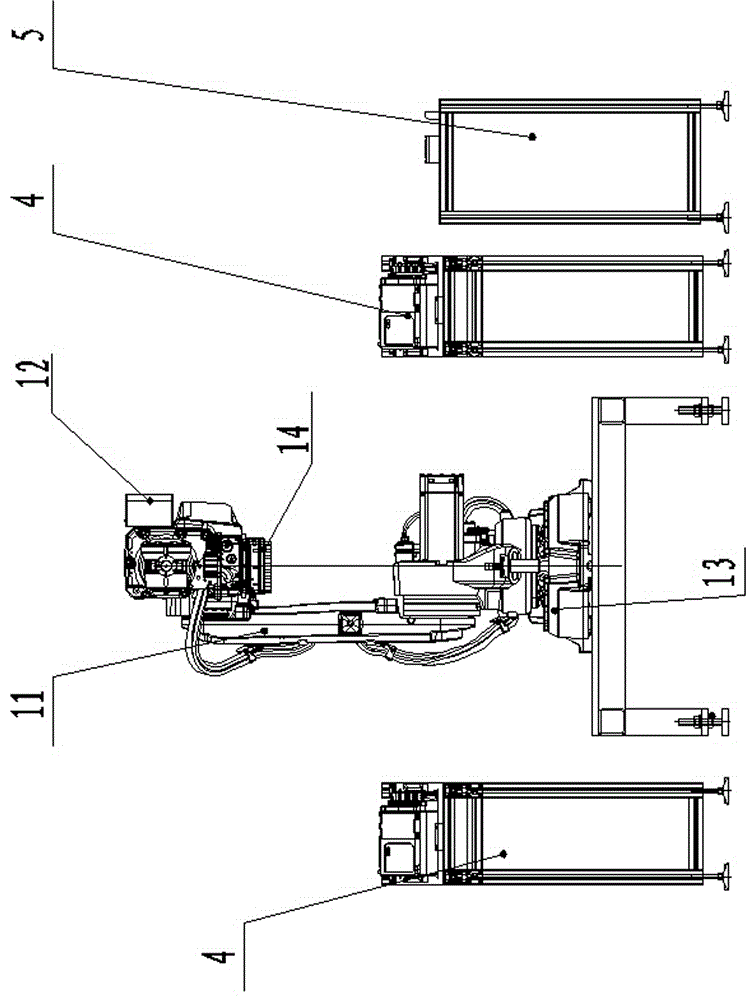

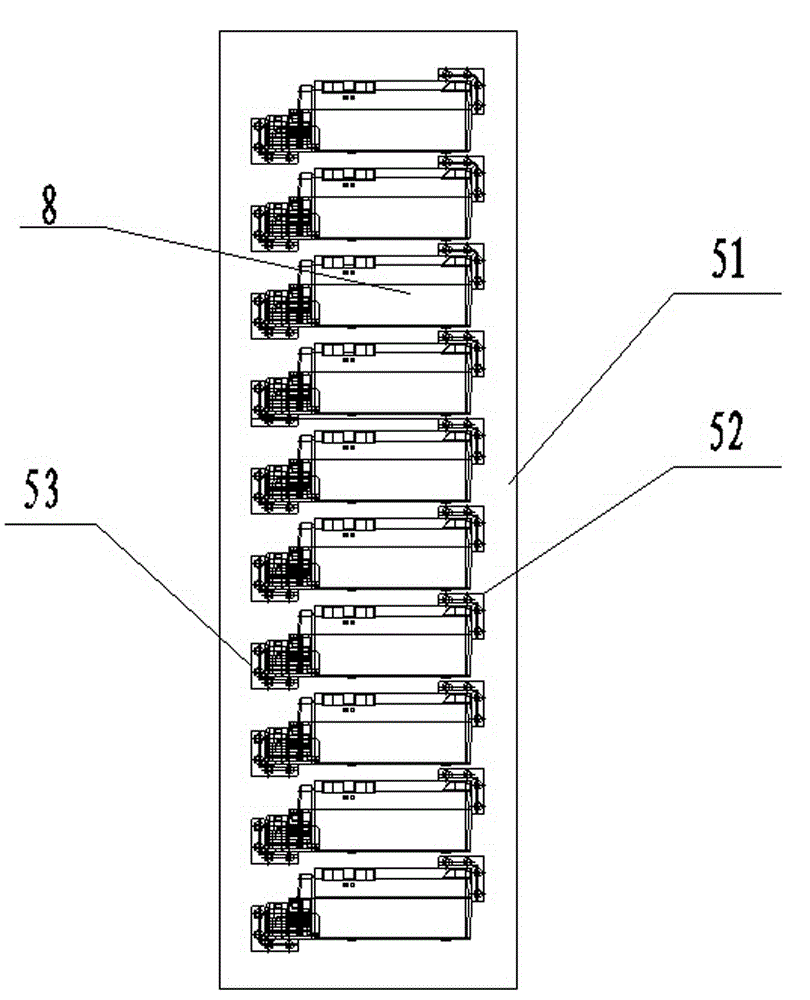

[0031] like Figure 1 to Figure 6As shown, a robot loading and unloading system for an electric energy meter of the present invention includes a turnover box assembly line device 7 and an electric energy meter assembly line device 6 arranged in a row, and the turnover box assembly line device 7 is provided with a stop device 2 (the stop device 2 is in the ZL 200920224136.5 has been disclosed, this embodiment will not be described in detail), it also includes a robot device 1, an electric energy meter sorting device 4 and an electric energy meter temporary storage device 5, and the robot device 1 is arranged on one side of the turnover box assembly line device 7 , the robot device 1 includes a robot base 13, a robot gripper 11 and a gripper control unit 12 for controlling the robot gripper 11, the robot gripper 11 is arranged on the robot base 13, and the robot gripper 11 is a sucker type manipulator, The gripper control unit 12 is in control connection with the robot gripper 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com