A method for pressing large-scale flat rubber products and production equipment using the same

A technology for rubber products and flat plates, applied in the field of rubber production equipment, can solve the problems of uneven rotation, affecting the lifting balance of the upper hot plate, and difficult to guarantee the quality of rubber products, so as to reduce the movement error and ensure the effect of movement balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

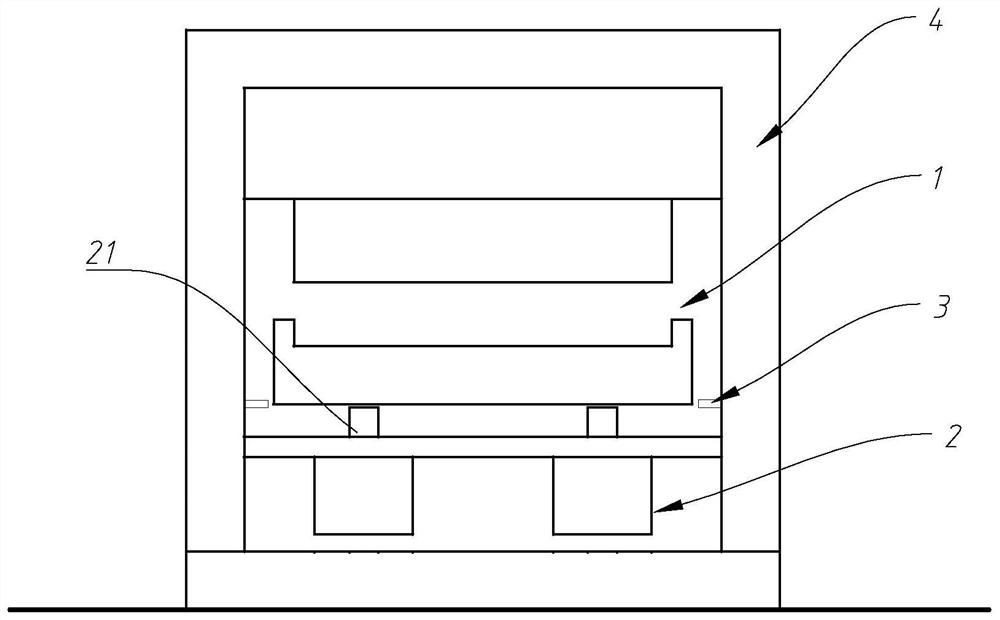

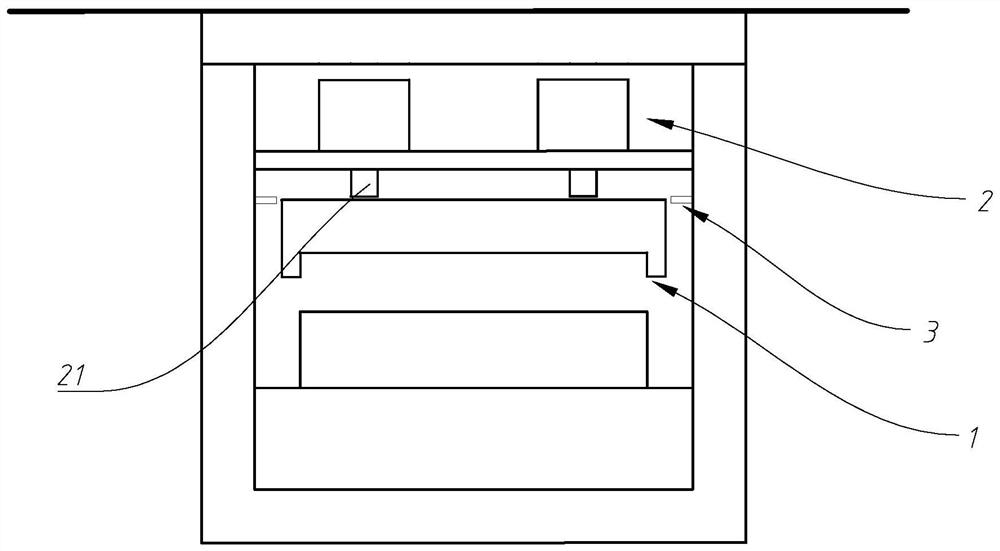

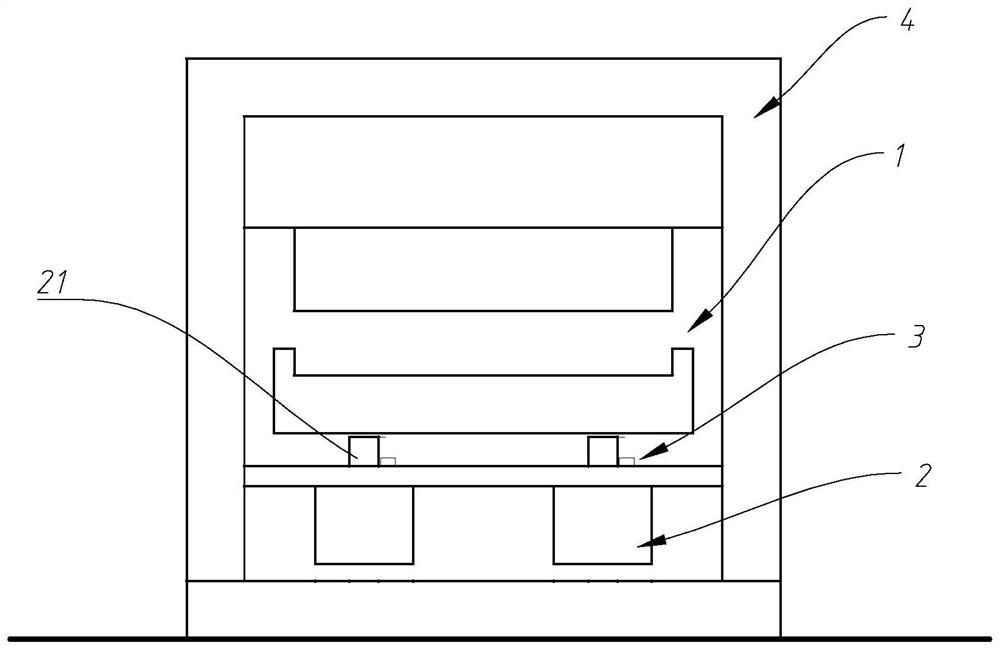

[0103] The pause position is set adjacent to the position where the rubber is pressed, as close as possible to the position where the rubber is pressed;

[0104] The specific distance value is determined according to the synchronous movement error of each driving source 2 .

[0105] Multiple driving sources simultaneously drive the lower mold 12 to move. At the beginning of the stroke, the synchronization is the best. The longer the stroke, the greater the movement error. Therefore, set the pause position close to the glue pressing position, that is, the position where the mold 1 and the rubber start to conflict. , to maximize the synchronization of the driving source and the balance of the mold 1, thereby ensuring that the rubber is evenly stressed.

[0106] A specific embodiment of the number of pauses in the present invention:

[0107] According to the length of the moving stroke, set several pause positions;

[0108] The corresponding driving source is started multiple t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com