High-safety efficient stirring mechanism for wet mixing granulator

A technology of wet mixing and stirring mechanism, which is applied to mixers, mixers with rotating stirring devices, applications, etc. It can solve the problems of prolonging the working hours of raw material crushing, incomplete crushing of raw materials, and low efficiency, so as to shorten the mixing time. The effect of granulation man-hours, enhanced auxiliary crushing effect, and overall safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

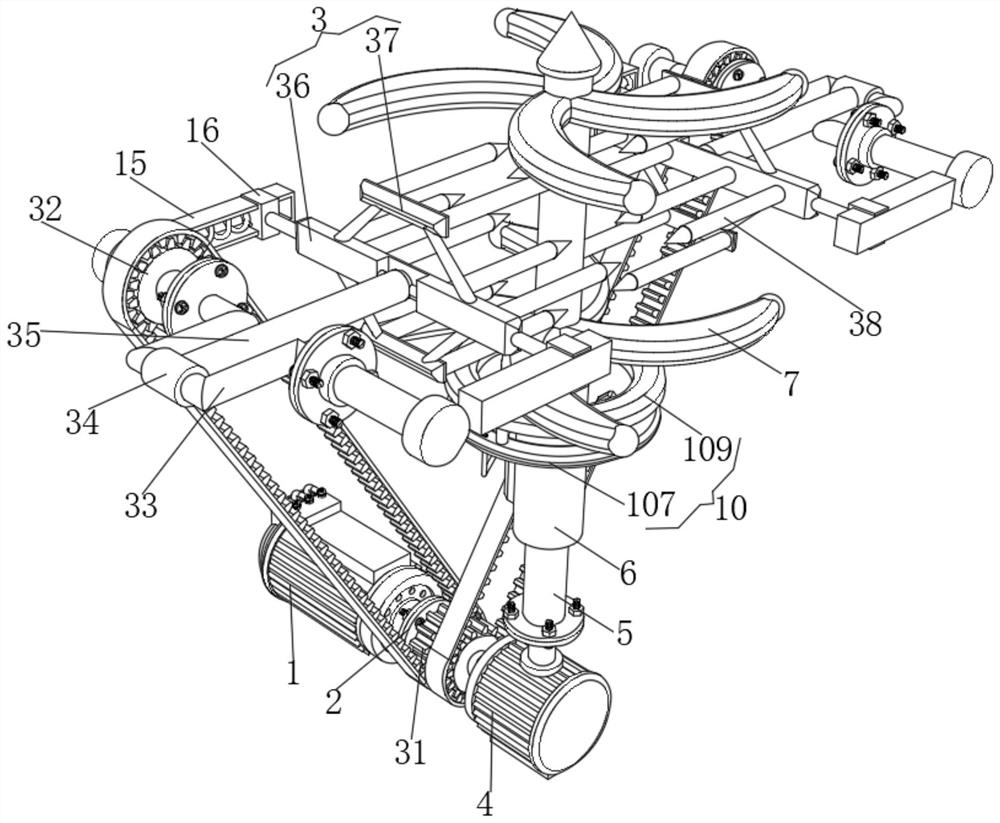

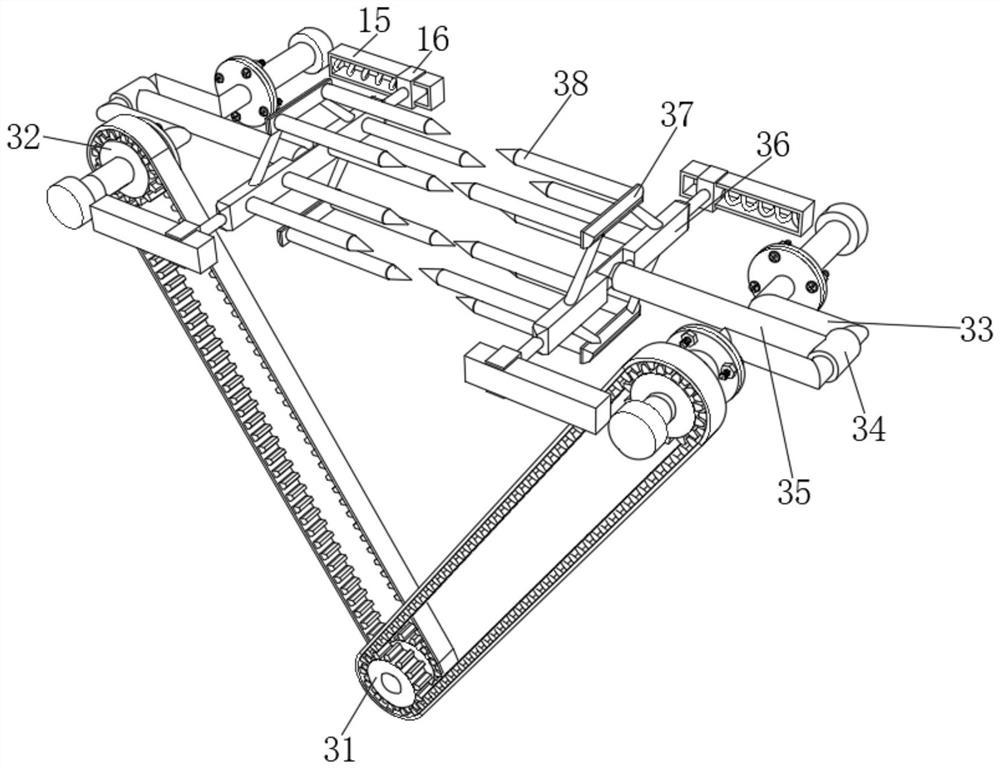

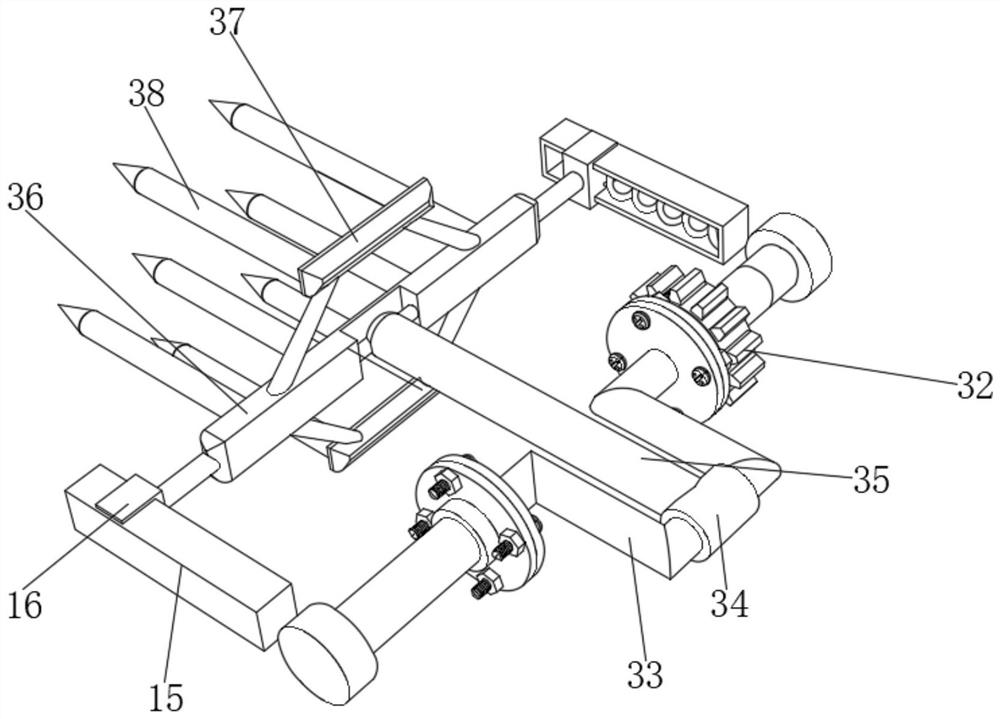

[0029] see Figure 1-6 , The present invention provides a technical solution: a high-efficiency stirring mechanism for a wet mixing granulator with high safety, comprising a drive motor 1, the output shaft of the drive motor 1 is fixedly connected with a coupling 2, and the Both sides are provided with auxiliary mechanisms 3. By setting auxiliary mechanisms 3, the driving synchronous wheel 31, the driven synchronous wheel 32, the concave rod 33, the drum 34, the connecting rod 35, the connecting frame 36, the auxiliary frame 37 and the crushing rod 38 When the two sets of stirring paddles 7 are stirring the raw materials in the granulator material cylinder, the auxiliary crushing treatment is performed on both sides of the semi-formed raw materials in the granulator material cylinder, which further improves the granulation and forming requirements of the raw materials, and also Shorten the stirring and granulating time of the raw materials, and improve the granulation efficien...

Embodiment 2

[0032] see Figure 1-6 , The present invention provides a technical solution: a high-efficiency stirring mechanism for a wet mixing granulator with high safety, comprising a drive motor 1, the output shaft of the drive motor 1 is fixedly connected with a coupling 2, and the Both sides are provided with an auxiliary mechanism 3, the auxiliary mechanism 3 includes a driving synchronous wheel 31, two sets of driving synchronous wheels 31 are fixed on the front and rear sides of the coupling 2, and the two sets of driving synchronous wheels 31 pass through the side away from the coupling 2. The synchronous belt drive is connected with a driven synchronous wheel 32, the inner cavity of the two sets of driven synchronous wheels 32 is fixedly connected with a concave rod 33, the center of the two sets of concave rods 33 is rotatably connected with a rotating drum 34, and the inner side of the rotating drum 34 is fixedly connected. There are connecting rods 35, the other side of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com