Quartz sand slag foamed light soil filling material for highway abutment backfill

A foam lightweight soil and filling material technology, which is applied in the field of civil engineering, can solve the problems that the pores of filler particles cannot be completely eliminated, the quality of the filler is poor, and the car jumps, etc., so as to eliminate the phenomenon of car jumping at the bridge head, reduce the construction cost, and solve the problem of stacking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

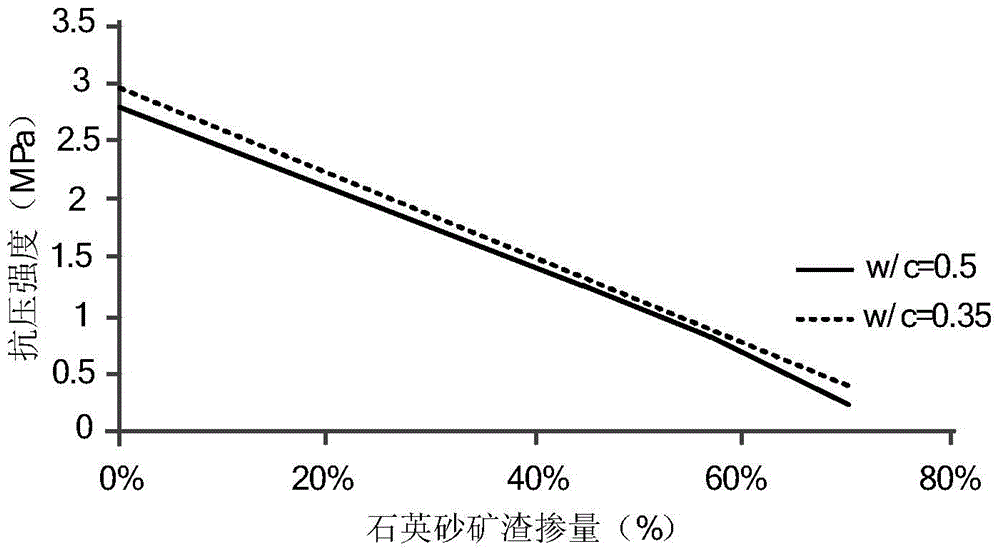

[0015] The foam light soil of the present invention is formed by foaming raw materials such as industrial tailings-quartz sand slag, cement, foaming agent, etc., the water-powder ratio is 30%-50%, and the dosage of quartz sand slag is 25%- 75%, the amount of cement is 25%-75%. The specific proportioning ratio can be within the scope provided by the present invention, and according to the comprehensively considered economic and strength requirements, several groups of different indoor proportioning tests can be carried out to determine the optimal proportioning ratio.

[0016] The research object in this embodiment is the abutment back of the bridge (culvert) of the Fengyang extension section of the Benghuai Expressway.

[0017] Raw material in the embodiment:

[0018] Cement: P II52.5 grade Portland cement, specific surface area 376m2 / kg;

[0019] Tailings: waste resources near the project site - quartz sand slag, density 2.54kg / m 3 , specific surface area 1314m 2 / kg, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com