Railway ballast cleaning device used for tamping wagon and tamping wagon

A technology of cleaning device and tamping vehicle, which is applied in the direction of roads, tracks, ballast layers, etc., can solve the problems of lack of automatic cleaning, heavy workload, and large operating time consumption, so as to achieve easy storage, high cleaning efficiency, and improved The effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

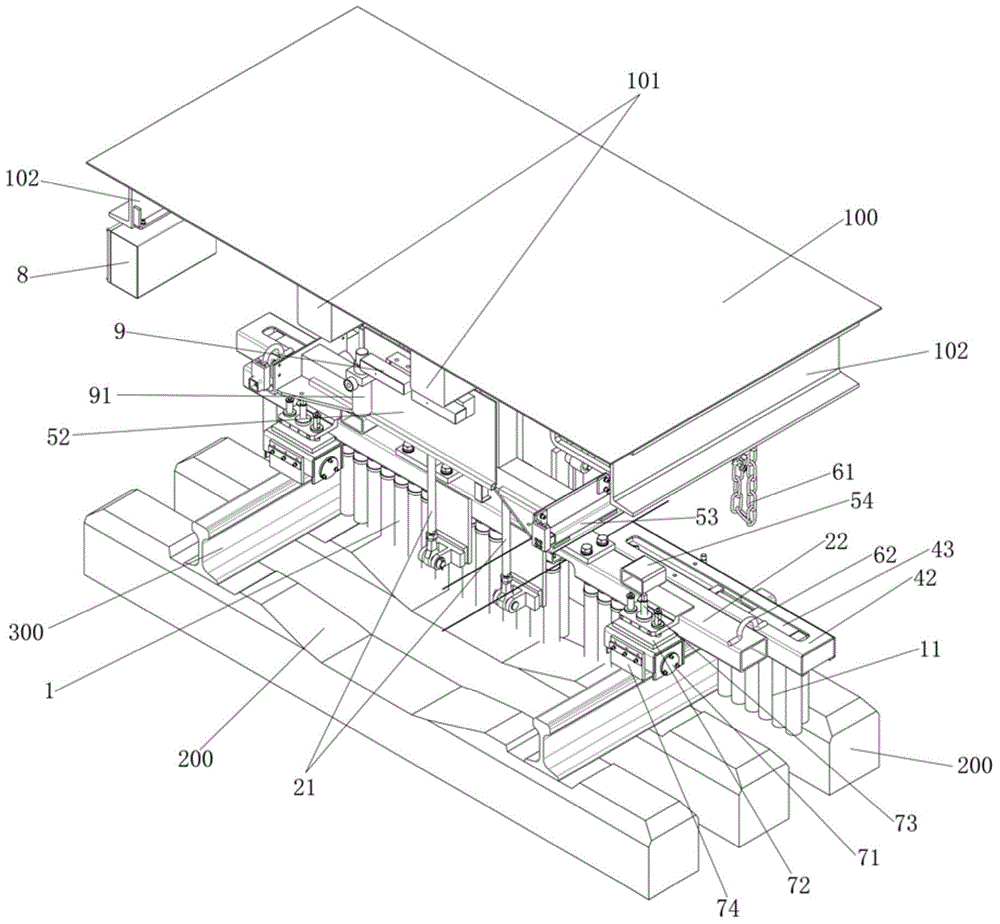

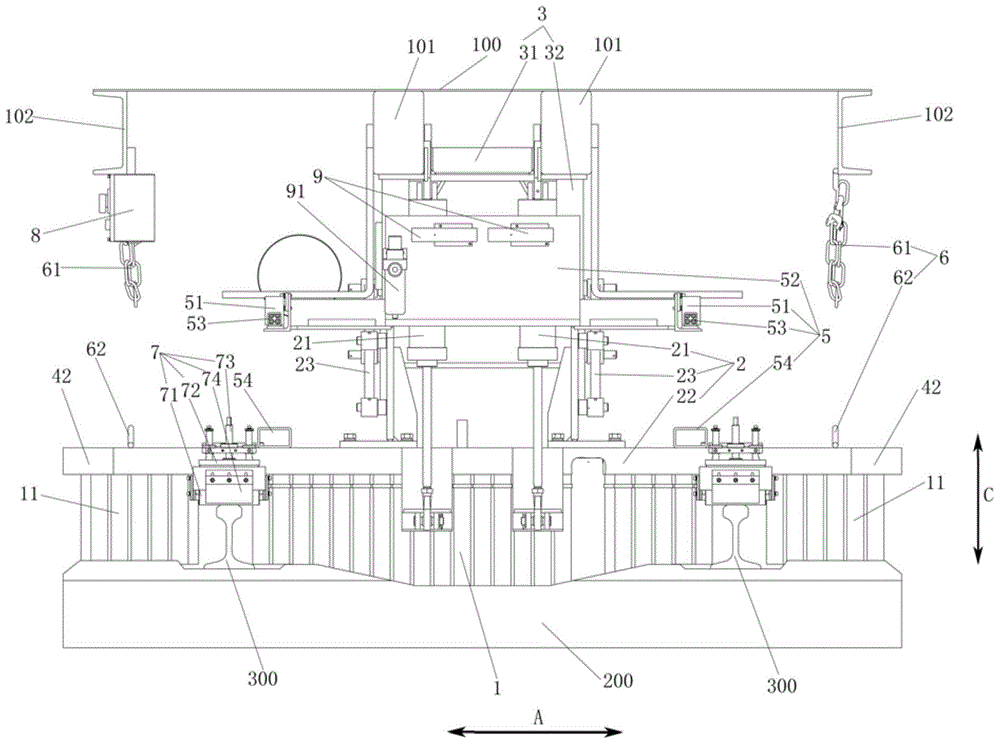

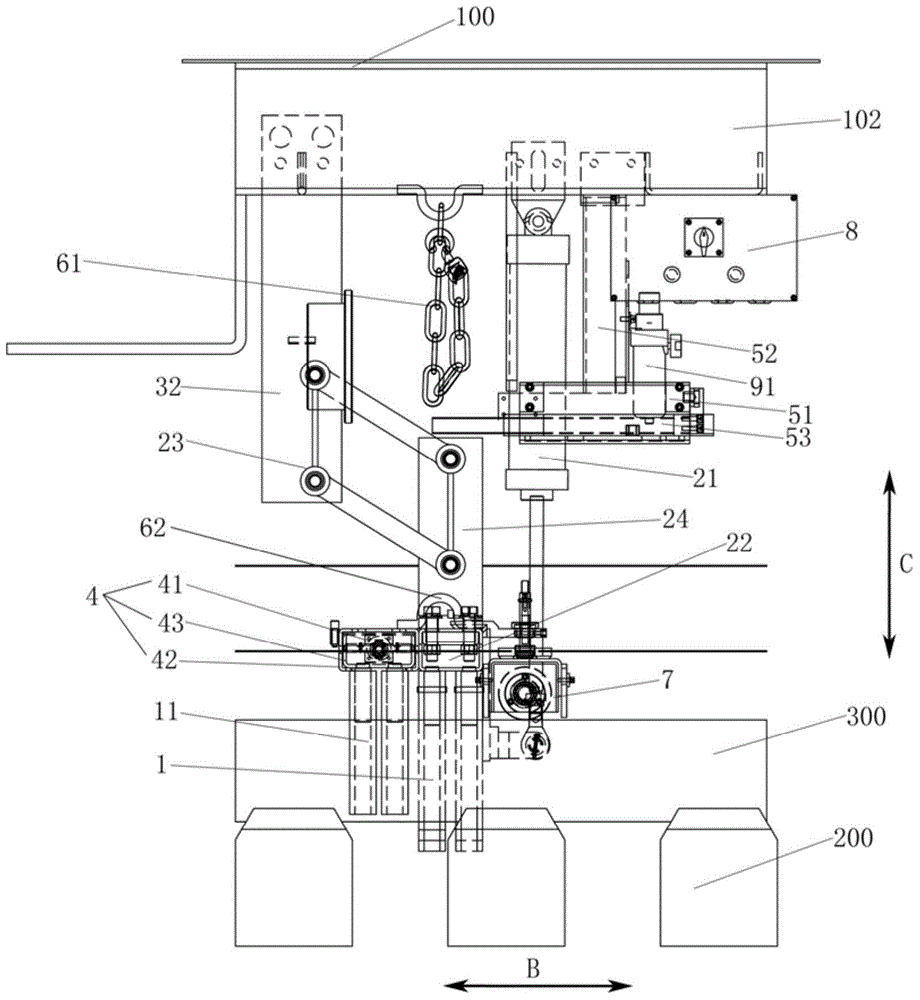

[0041] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0042] According to one aspect of the present invention, the present invention provides a ballast cleaning device for a tamping vehicle, the ballast cleaning device has an installation part that can be installed under the tamping vehicle 100, and the ballast cleaning device includes a cleaning structure 1 and a lifting structure 2, the lifting structure 2 is used to drive the cleaning structure 1 up and down so that the cleaning structure 1 can contact the ballast and perform ballast cleaning operations, the cleaning structure 1 includes cleaning parts arranged along the lateral direction A of the ballast cleaning device.

[0043] Such as Figure 1 to Figure 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com