Waterpower automatic silt-washing device of inverted siphon in pressure water delivery pipe

A water pipeline and hydraulic automatic technology, which is applied in the direction of water supply devices, water supply main pipelines, cleaning sewer pipelines, etc., to achieve the effects of small impact on project operation, prevention of sedimentation at the bottom of pipes, and water conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

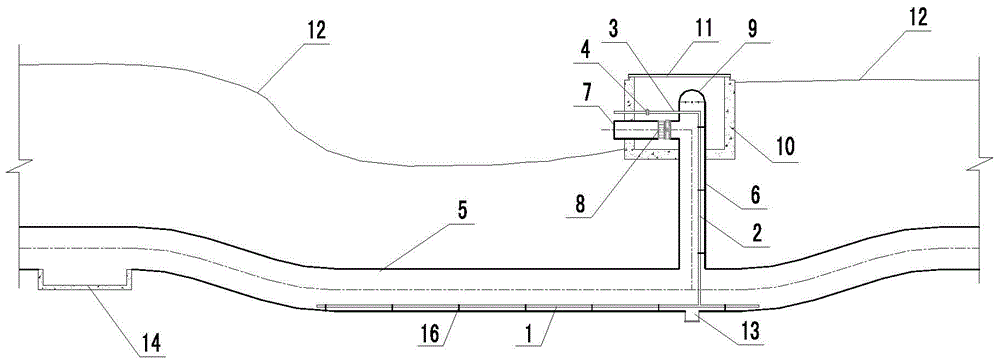

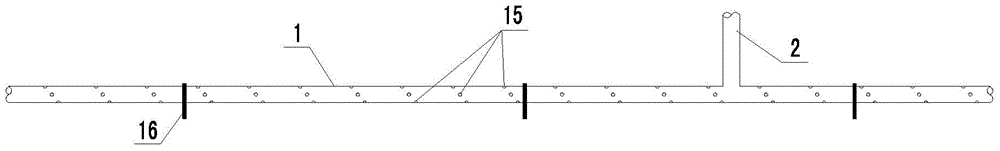

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] like figure 1 and figure 2 As shown, the present invention has a pressure water pipeline inverted siphon hydraulic automatic silting device, including a horizontal silt suction pipe 1 for sucking silt, a vertical mud pipe 2 for mud transportation and a surface mud discharge for mud discharge Pipe 3; the horizontal silt suction pipe 1 is located at the bottom of the inverted siphon pipe 5 of the water delivery pipeline, and is made of stainless steel steel pipes. Connected to the inner wall of the inverted siphon pipe 5, the fixing part 16 is an Ω-shaped stainless steel gasket, and after fixing the horizontal silt suction pipe 1, it is welded on the bottom inner wall of the inverted siphon pipe 5, and the total area of the orifices of all the silt suction holes 15 is smaller than that of the horizontal silt suction pipe The cross-sectional area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com