Integrated polyurethane synchronous belt and manufacturing method thereof

A polyurethane and synchronous belt technology, applied in chemical instruments and methods, transmission belts, mechanical equipment, etc., can solve problems such as low production efficiency, hidden safety hazards, and complicated preparation processes, and achieve the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

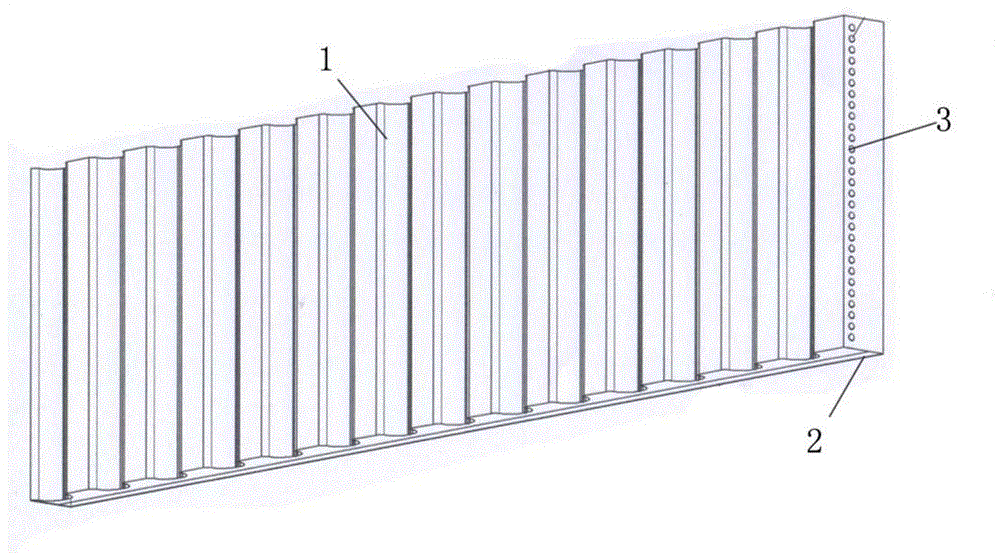

[0020] Such as figure 1 As shown, the present invention is an integrated polyurethane synchronous belt, which includes a synchronous belt main body formed by an integrally formed hard polyurethane tooth layer 1 and a soft polyurethane base layer 2, and the hardness (Shore) of the rigid polyurethane is 91- 93A, the hardness (Shore) of soft polyurethane is 55-60A. The main body of the synchronous belt is provided with a metal skeleton 3 . In this embodiment, the metal skeleton 3 is arranged in the hard polyurethane tooth layer 1 . The metal skeleton includes several metal wires located on the same plane, the several metal wires are parallel to each other with intervals between them, and the metal wires are 1mm steel wires.

[0021] The following is the preparation method of the one-piece polyurethane synchronous belt. It is to put a metal skeleton in a tooth-shaped metal mold, pour a layer of high-hardness polyurethane for forming a hard polyurethane tooth layer, and wait unti...

Embodiment 2

[0023] In this embodiment, the metal skeleton is composed of at least one layer of metal mesh, and the metal mesh is braided by metal wires, and the metal wires are 2mm steel wires.

[0024] The following is the preparation method of the one-piece polyurethane synchronous belt. It is to put a metal skeleton in a tooth-shaped metal mold, pour a layer of high-hardness polyurethane for forming a hard polyurethane tooth layer, and wait until the layer of polyurethane is in a gel state Finally, another soft polyurethane used to form a soft polyurethane base layer is poured in. After the soft polyurethane is in a gel state, it is pressurized and vulcanized. After 35 minutes, the mold is demoulded, and then the secondary vulcanization is carried out in an oven at 120 ° C for 11 hours. .

[0025] Compared with the prior art, the present invention adopts pouring a layer of polyurethane with higher hardness in the tooth-shaped metal mold, and pouring another soft polyurethane with hardn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com