Anti-skid differential and automobile

A technology of anti-skid differential and differential case, which is applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., which can solve the problem of poor passability, traction and driving safety, and the inability to transmit large Torque, coil spring installation space is limited, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

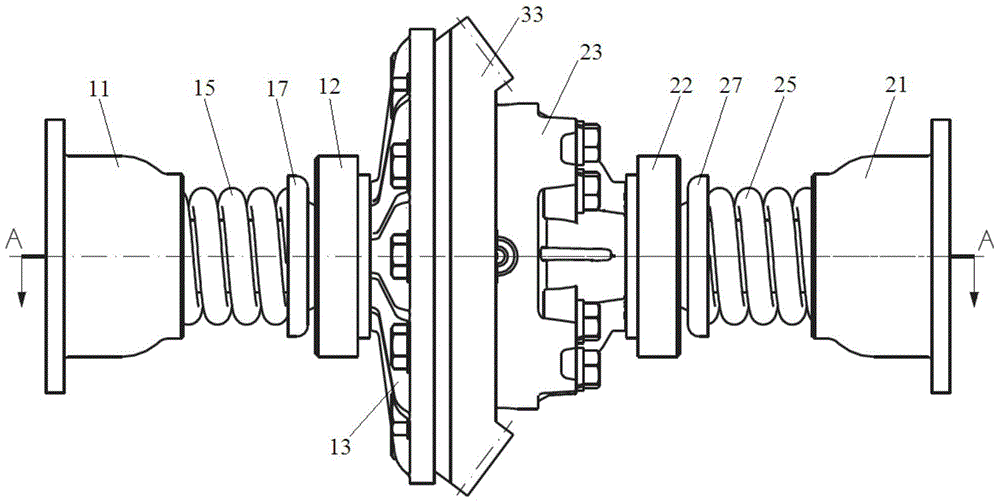

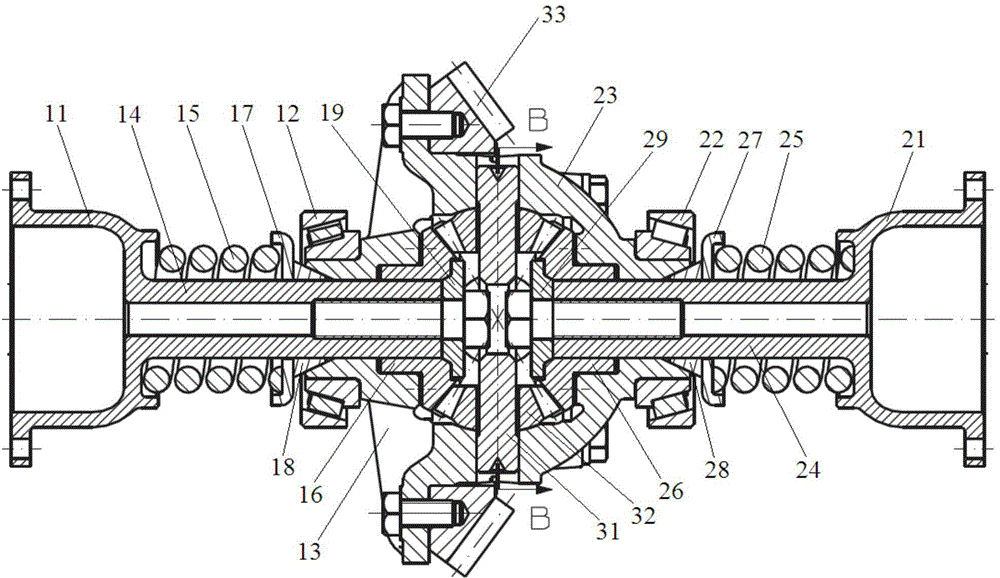

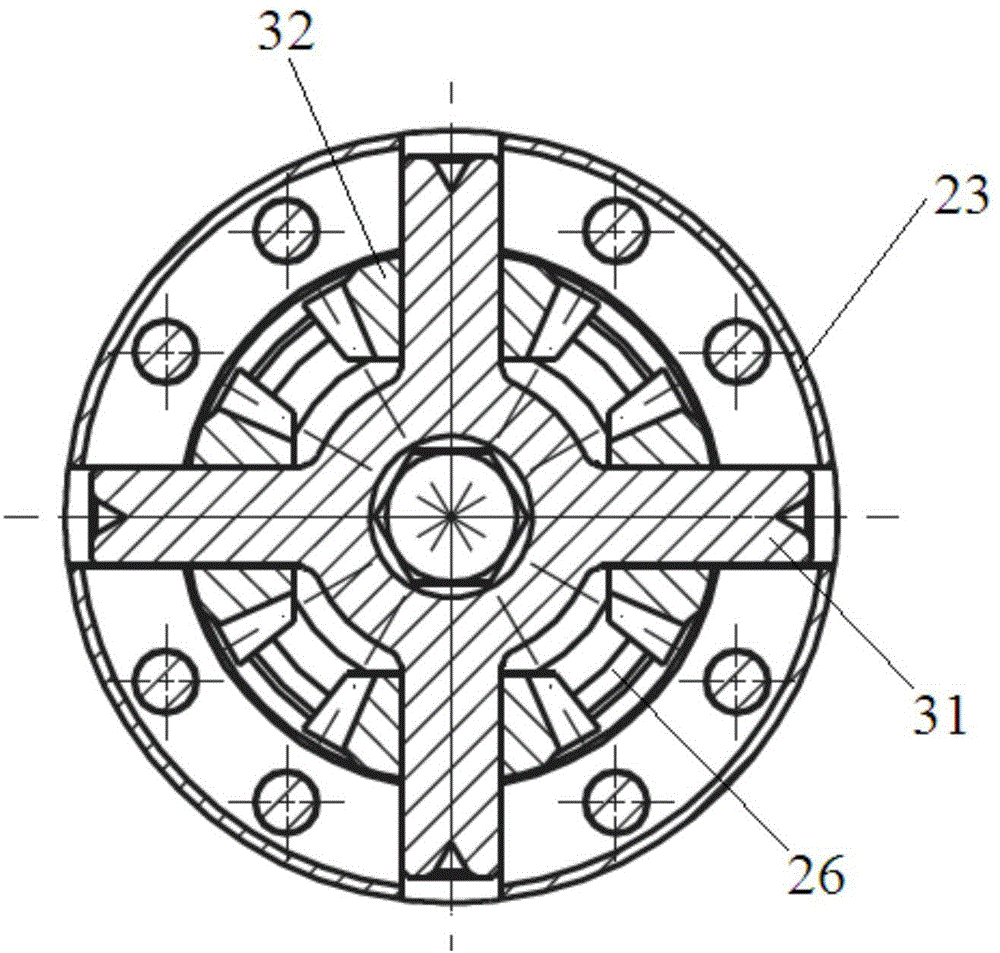

[0038] Such as Figure 1-3 As shown, the embodiment of the present invention provides a limited slip differential, which includes a first output flange 11, a first bearing 12, a first differential case 13, a first half shaft 14, a first screw Spring 15, first side gear 16, second output flange 21, second bearing 22, second differential case 23, second half shaft 24, second coil spring 25, second side gear 26, cross Shaft 31, planetary gear 32 and main minus driven bevel gear 33, wherein:

[0039] The first output flange 11 and the second output flange 21 are used to fix the left wheel and the right wheel respectively, so as to drive the left wheel and the right wheel to rotate; the first bearing 12 and the second bearing 22 are installed respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com