Auxiliary measuring rod for converter valve conduction tests

A technology of conduction test and auxiliary measurement, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, etc. It can solve the problems of increased danger for test personnel, and achieve the effect of convenient and flexible testing, convenient testing, and increased convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

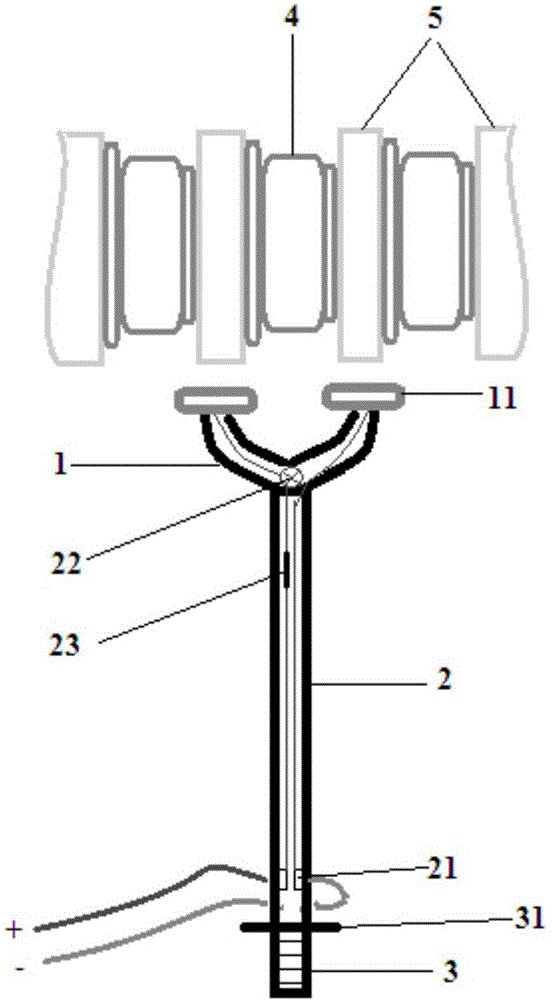

[0020] Such as figure 1 As shown, an auxiliary measuring rod for the conduction test of the converter valve is used for the test instrument to conduct the conduction test of a plurality of thyristors 4 in the converter valve. The auxiliary measuring rod includes a rod head 1, a rod body 2 and a The handle 3, the rod head 1 is a hollow U-shaped structure, the rod body 2 is a hollow telescopic rod, and the inside of the telescopic rod communicates with the inside of the rod head 1, and the two top ends of the rod head 1 are respectively provided with contact ends 11, and the contact ends 11 are respectively The wires pass through the rod head 1 and the inside of the telescopic rod in turn to connect with the testing instrument.

[0021] The contact end 11 is a metal end, the metal end is hinged with the top of the rod head 1, and its range of motion is 0-120 degrees. The spacing of the end aluminum blocks 5 is equal.

[0022] The contact end 11 on one top of the rod head 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com