Light guiding type reflective film plate and manufacturing method thereof

A production method and technology of reflective film, which are applied to illuminated signs, instruments, display devices, etc., can solve the problems of being unsuitable for large-scale popularization and application of traffic engineering, and the pattern display is not full and uniform, and achieves high light source utilization efficiency. , Beautify the night scene of the city road, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing of description, the present invention will be further described.

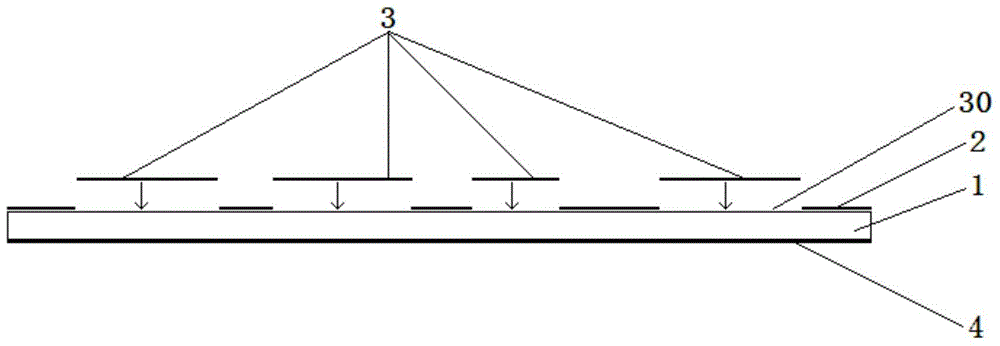

[0035] Such as figure 1 A light-guiding reflective film plate is shown, including a fully transparent substrate 1, a hollow reflective base film 2 and a reflective pattern film 3 attached to the top surface of the substrate 1, and a nano-transparent composite film sprayed on the bottom surface of the substrate 1. powder layer 4; the reflective pattern film 3 is pasted on the hollowed-out position 30 of the hollowed-out reflective bottom film 2, figure 1 The middle arrow shows the direction of overlaying. The substrate 1 is preferably an optical-grade acrylic plate, which can be spliced by equal layouts.

[0036] The present invention also provides for the production of figure 1 The manufacturing method of the light-guiding type reflective sheeting shown includes the following steps:

[0037] 1) Prepare substrate materials and reflective materials;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com