Horizontal tape coiling machine

A reeling and horizontal technology, applied in the field of reeling machines, can solve the problems of unraveling the tape roll, the maximum diameter of the webbing roll cannot be too large, and the shaft core is difficult to pull out, etc., to achieve good bearing capacity, avoid wear, and reduce friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

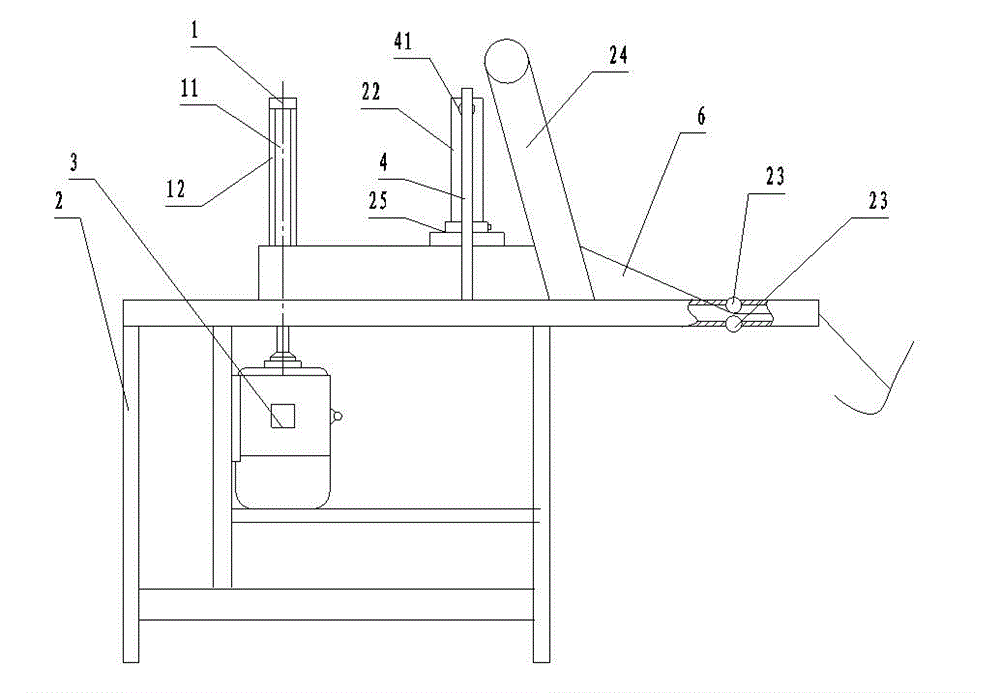

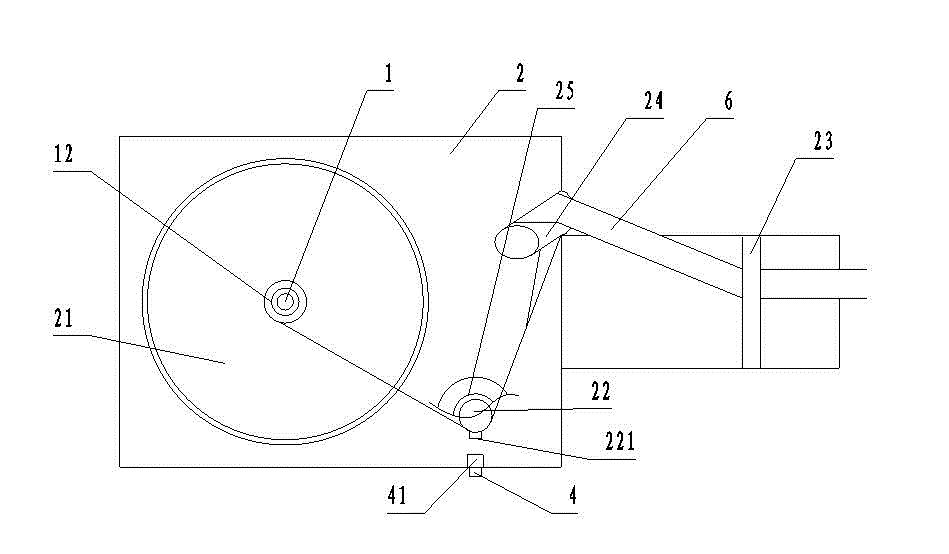

[0024] Example 1, such as figure 1 , 2 Shown, a kind of horizontal reeling machine, it comprises shaft core 1, frame 2, and frame 2 is fixed with feeding system, turntable 21, motor 3 and electric control system, and feeding system is mainly composed of horizontal feeding guide The roller 23 and the oblique guide roller 24 are composed of two parallel horizontal feed guide rollers 23 fixed on the front end of the frame 2 to ensure that the webbing enters horizontally and smoothly. The oblique guide roller 24 is located on the horizontal feed guide roller 23 The rear end of the shaft core 1 is vertically fixed to the center of the turntable 21 and is connected with the motor 3, the turntable 21 is parallel to the ground, and a strip bar 22 parallel to the shaft core 1 is vertically fixed on the plane outside the turntable 21. 22 is fixed with a belt pressing piece 25, generally the belt pressing piece 25 is fixed by a set screw, and the belt pressing piece can be adjusted long...

Embodiment 2

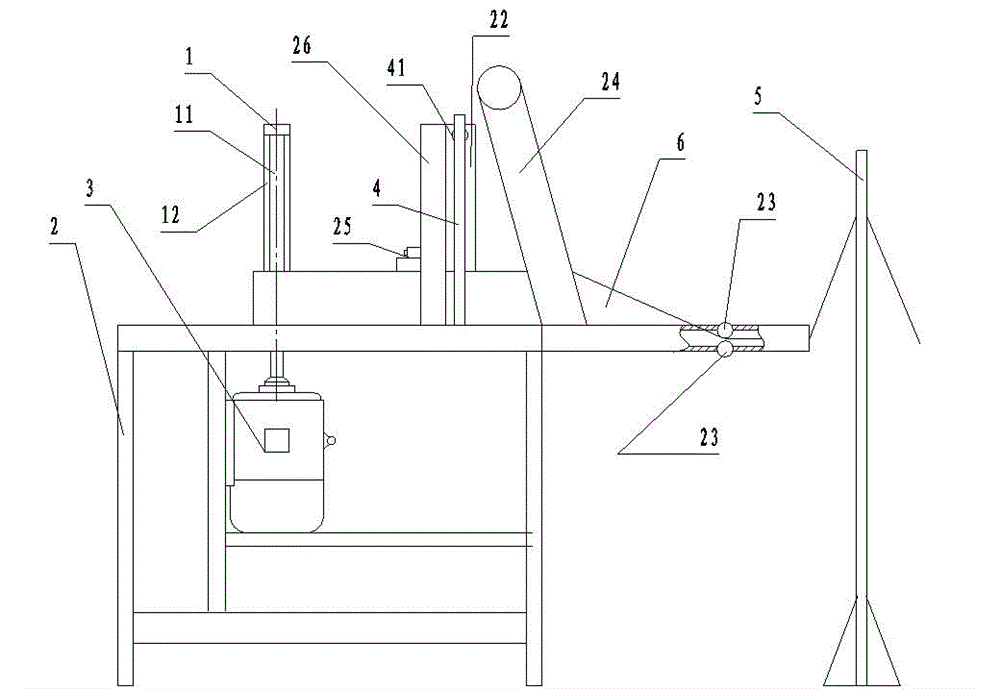

[0025] Example 2, such as image 3 , 4 As shown in , 5, it is further improved on the basis of embodiment 1, and is suitable for a kind of horizontal tape winding machine with large flexibility. It includes a shaft core 1 and a frame 2, and the frame 2 is fixed with a Belt system, turntable 21, motor 3 and electric control system, the belt feeding system is mainly composed of horizontal feeding guide rollers 23 and oblique guide rollers 24, and two horizontal feeding guide rollers 23 parallel up and down are fixed on the front end of frame 2 , to ensure that the webbing enters horizontally and smoothly, there is a horizontal guide bar 5 higher than the horizontal guide roller 23 before the horizontal guide roller 23, so as to increase the observation distance before the ribbon enters the winding belt, so as to have sufficient Time to resolve any webbing knots that may have occurred. There are also multiple horizontal feed guide rollers 23 arranged between the two vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com