Variable frequency motor and water supply system

A frequency conversion motor and frequency conversion module technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of low integration, poor reliability, large frequency conversion motor, etc., achieve high integration, fewer failure points, and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

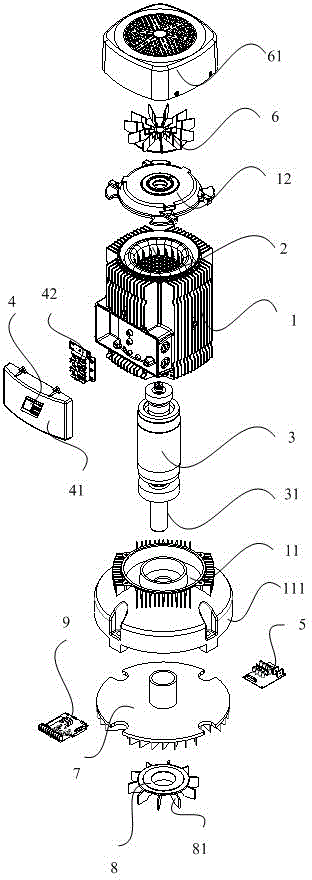

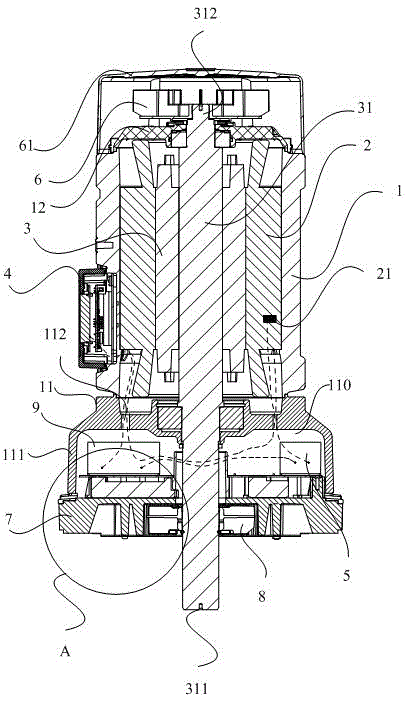

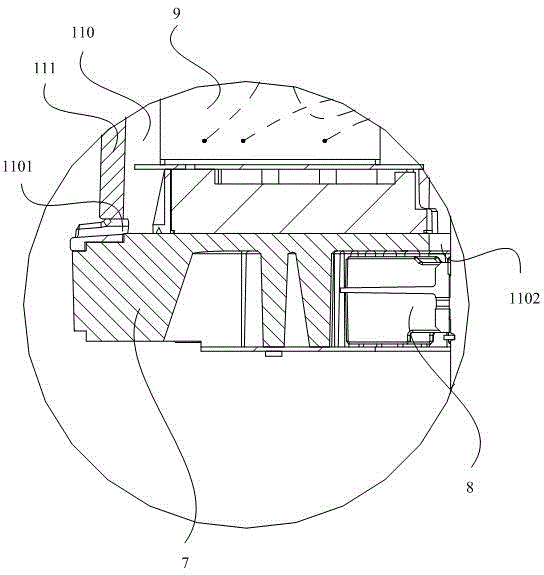

[0027] like Figure 1-Figure 4 As shown, the variable frequency motor in this embodiment includes a casing 1, a stator 2, a rotor 3, a frequency conversion module 5 and a motor fan 6, the stator 2 and the rotor 3 are installed in the casing 1, the rotor 3 has a rotating shaft 31, and one end of the casing 1 has an output End cover 11, the other end of the housing 1 has a non-output end cover 12, one end of the rotating shaft 31 is an output end 311, the other end of the rotating shaft 31 is a non-output end 312, and the output end 311 of the rotating shaft 31 extends out of the output end cover of the housing 1 11. The non-output end 312 of the rotating shaft 31 protrudes from the non-output end cover 12 of the housing 1 , the motor fan 6 is fixed on the non-output end 312 of the rotating shaft 31 , and the motor fan 6 is covered by the windshield 61 . Among them, in order to highly integrate the frequency conversion module 5 on the casing 1 and meet the heat dissipation requi...

Embodiment 2

[0032] like Figure 5-Figure 7 As shown, the variable frequency motor in this embodiment includes a casing 1, a stator 2, a rotor 3, a frequency conversion module 5 and a motor fan 6, the stator 2 and the rotor 3 are installed in the casing 1, the rotor 3 has a rotating shaft 31, and one end of the casing 1 has an output End cover 11, the other end of the housing 1 has a non-output end cover 12, one end of the rotating shaft 31 is an output end 311, the other end of the rotating shaft 31 is a non-output end 312, and the output end 311 of the rotating shaft 31 extends out of the output end cover of the housing 1 11. The non-output end 312 of the rotating shaft 31 protrudes from the non-output end cover 12 of the housing 1 , the motor fan 6 is fixed on the non-output end 312 of the rotating shaft 31 , and the motor fan 6 is covered by the windshield 61 . Among them, in order to highly integrate the frequency conversion module 5 on the casing 1 and meet the heat dissipation requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com