Assembly machine for commutator, meson and rotor assembly

A commutator and assembly machine technology, applied in the direction of electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problems of unguaranteed product quality, inaccurate rotor positioning, low production capacity, etc., and achieve product yield rate The effect of upgrading, liberating labor force and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

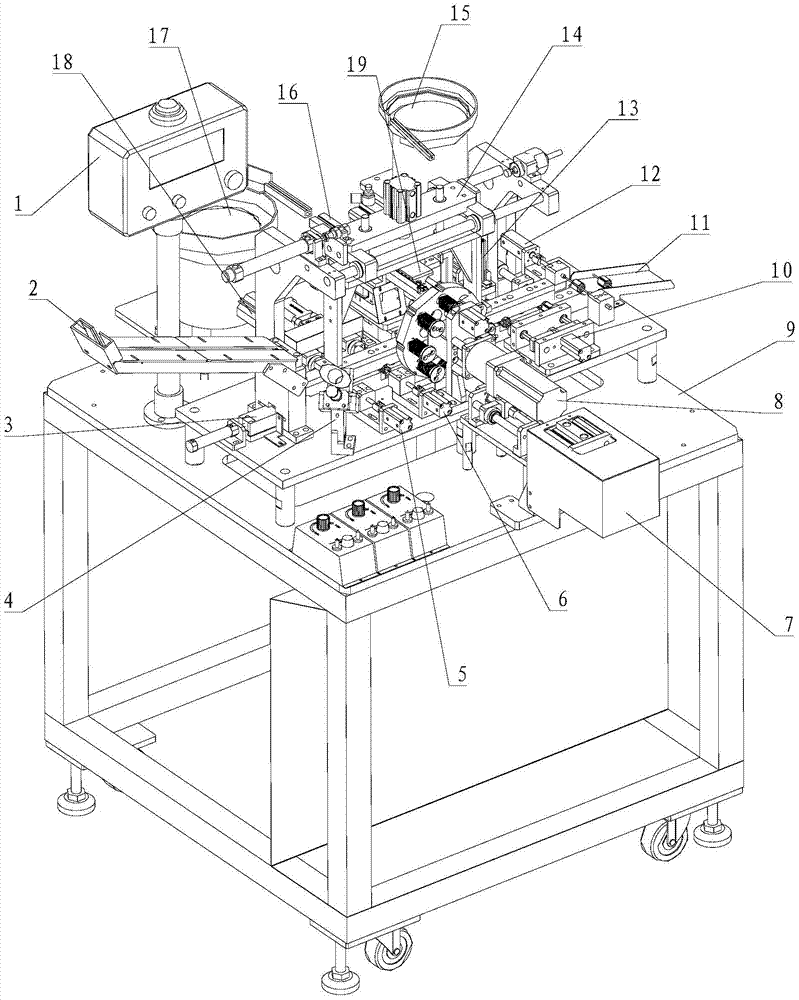

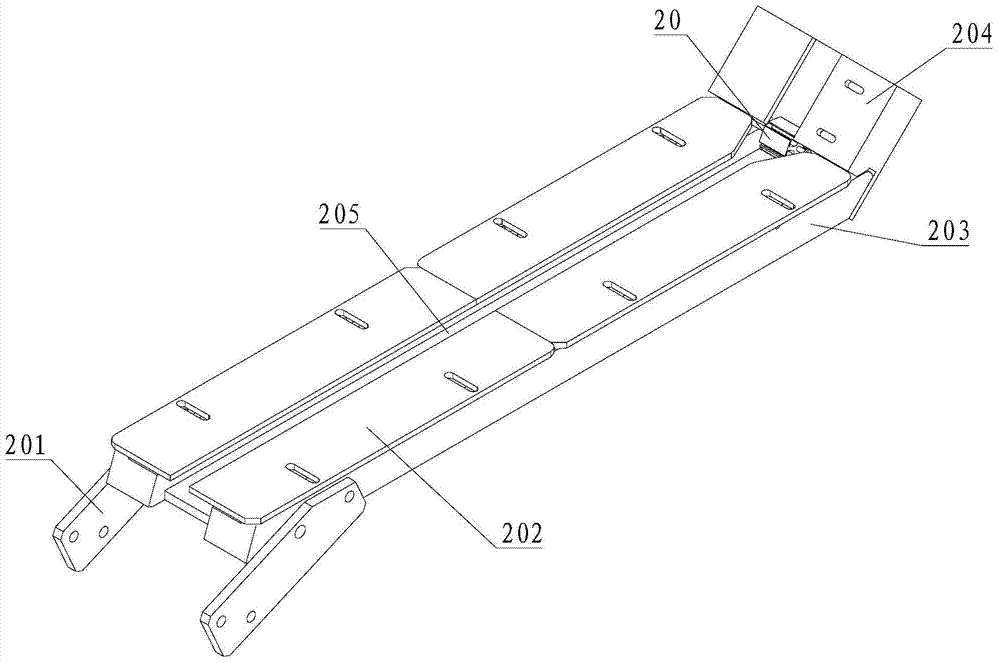

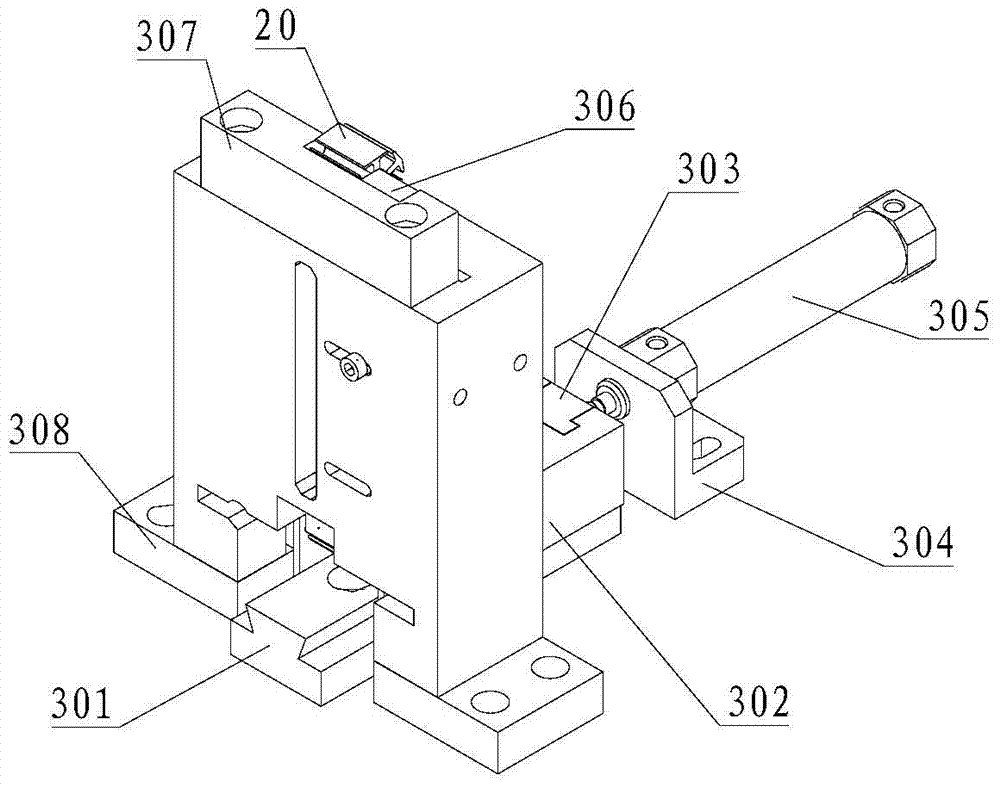

[0082] see Figure 1 to Figure 17 , Embodiment 1 of the present invention is:

[0083] A commutator, meson and rotor assembly machine, including a frame and a large working plate 9 arranged above the frame, and also includes a plurality of fixed rotors arranged in a line arranged on the large working plate 9 Seat 1406, the rotor feeding device arranged at one end of the rotor-sending fixed seat 1406, the rotor delivery mechanism 14 arranged above the rotor-sending fixed seat 1406, the rotor positioning device arranged at one side of the rotor-sending fixed seat 1406, and the The commutator press-in device, the meson press-in device, the glue dispensing mechanism 4, the meson vibrating plate 15, the commutator vibrating plate 17 and the finished product discharge channel 11 provided on the fixed seat 1406.

[0084] The displacement path of the rotor conveying mechanism 14 passes at least through the rotor positioning device, the commutator pressing device and the meson pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com