Grinder and grinding machine

A technology of grinding discs and grinding machines, which is applied to grinding machine tools, grinding devices, grinding tools, etc., can solve the problems of high wear degree and large amount of movement, and achieve the effect of grinding uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

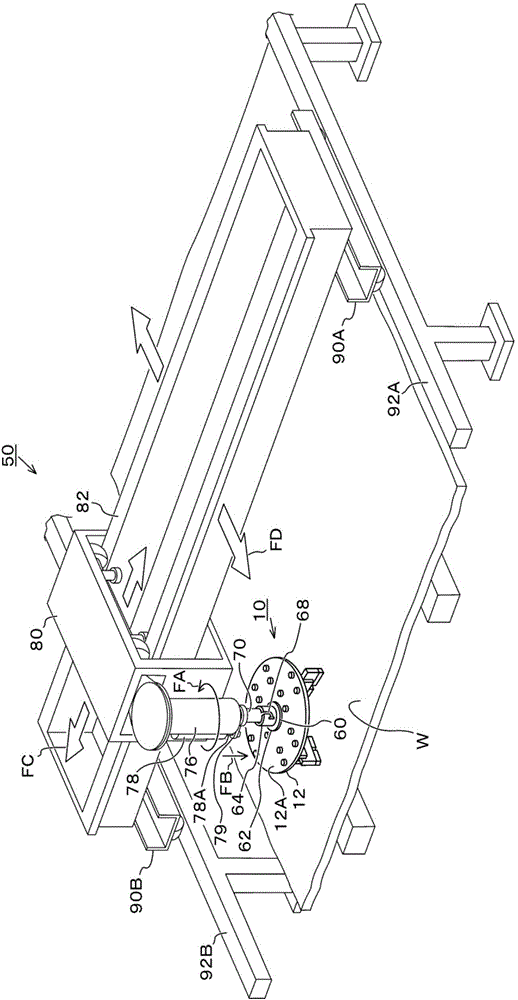

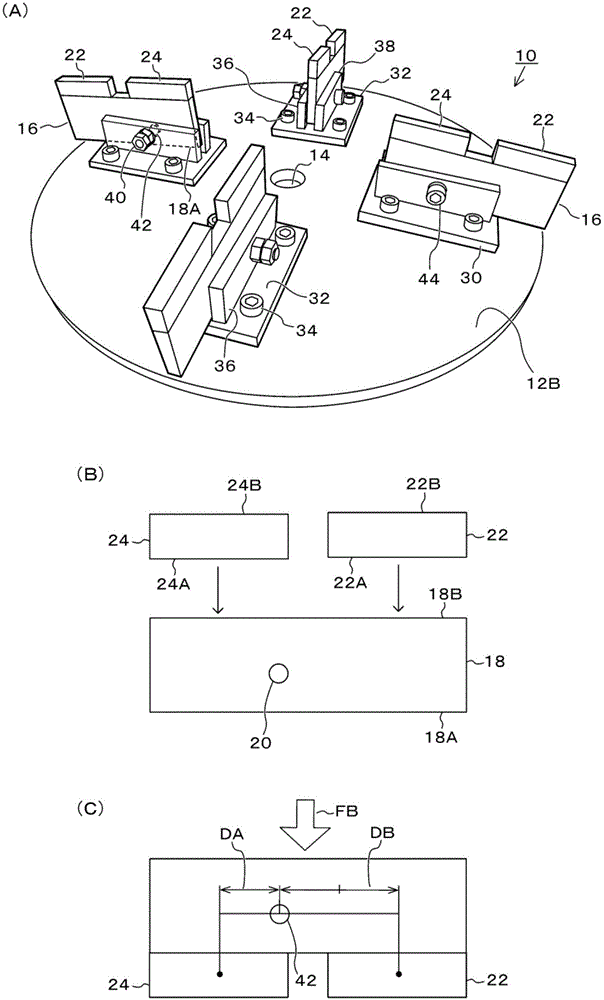

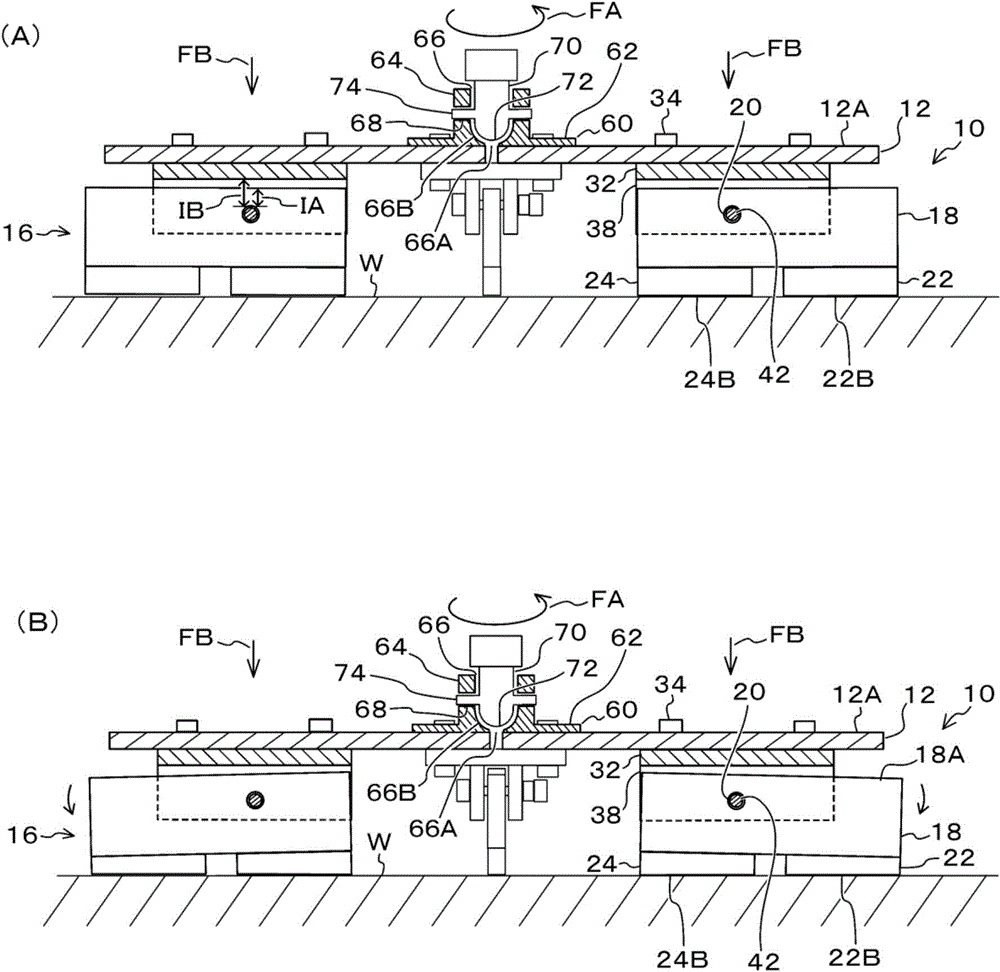

[0025] First, refer to Figure 1 ~ Figure 3 Example 1 of the present invention will be described. figure 1 It is an external perspective view showing the overall structure of the grinder of this embodiment. Such as figure 1 As shown, the grinder 50 of this embodiment is used to grind the surface of an object W such as a stone, and this embodiment is an example of a uniaxial type. The grinder 50 is equipped with a grinding disc 10 at the top of the rotating shaft 70 of the main shaft 76, and the grinding disc 10 can be as figure 1 Rotate as indicated by arrow FA in . In addition, a hydraulic cylinder 78 is provided on the side of the spindle 76 as a pressing member for pressing the rotating shaft 70 toward the object W (see arrow FB). A rod 78A of the hydraulic cylinder 78 is connected to the rotary shaft 70 via a connection member 79 . In addition, the spindle 76 is a self-propelled type capable of moving along the surface of the object W. As shown in FIG.

[0026] Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com