Shading composite material

A composite material and composite layer technology, applied in the direction of synthetic resin layered products, lamination, layered products, etc., can solve the problems of endangering the life, rest and health of urban residents, poor window isolation ability, energy loss, etc. The effect of promoting use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

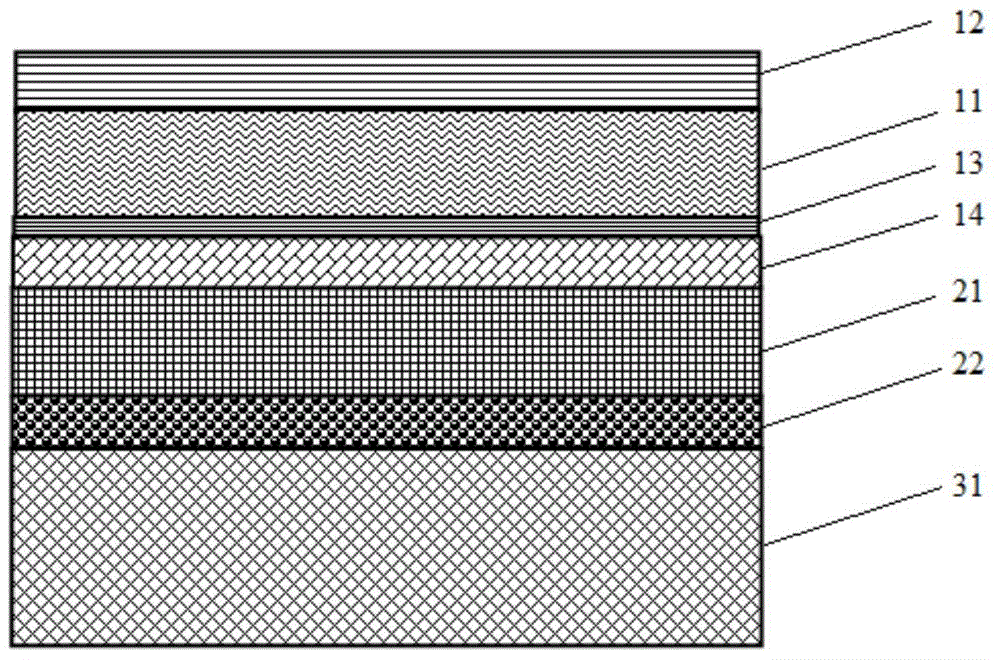

Embodiment 1

[0053] figure 1 It is a structural schematic diagram of the light-shielding composite material of Example 1. The shading composite material sequentially includes a stacked colored ink printing layer 12, a first transparent film layer 11, a first vacuum aluminized layer 13, a composite adhesive layer 14, a second transparent film layer 21, a polyethylene Laminating composite layer 22, and a non-woven fabric layer 31.

[0054] Raw materials and sources used in the preparation method of the light-shielding composite material:

[0055] 1. The first transparent film layer 11 and the second transparent film layer 21 are all made of PET film with a thickness of 12 microns, with a light transmittance of 88%, a 45° gloss of 136 gloss units, and a haze of 2.25%. The surface is treated by corona After wetting tension ≥ 48mN / m. Other physical properties are in line with the national standard GB / T16958-2008 "Biaxially Oriented Polyester Film for Packaging".

[0056] ②The printing equip...

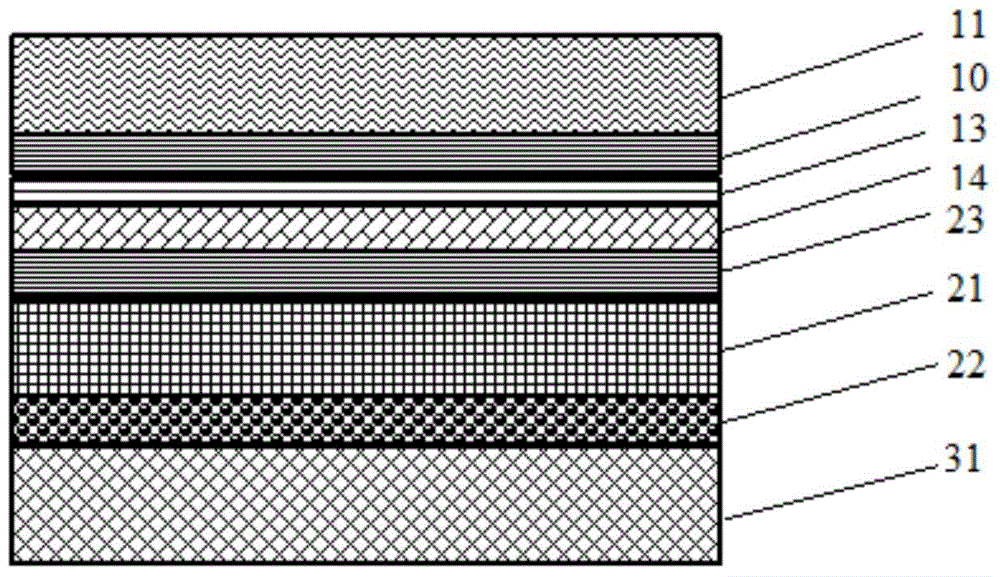

Embodiment 2

[0087] figure 2 It is a structural schematic diagram of the light-shielding composite material of Example 2. The light-shielding composite material sequentially includes a first transparent film layer 11, a colored paint layer 10, a first vacuum aluminized layer 13, a composite adhesive layer 14, a second vacuum aluminized layer 23, a second A transparent film layer 21 , a coating composite layer 22 and a non-woven fabric layer 31 .

[0088] Raw materials and sources used in the preparation method of the light-shielding composite material:

[0089] 1. The first transparent film layer 11 and the second transparent film layer 21 are all made of PET film with a thickness of 12 microns, with a light transmittance of 87%, a 45° gloss of 125 gloss units, and a haze of 2.27%. After corona treatment, the surface Wetting tension ≥ 48mN / m. Other physical properties are in line with the national standard GB / T16958-2008 "Biaxially Oriented Polyester Film for Packaging".

[0090] ② Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Longitudinal tensile strength | aaaaa | aaaaa |

| Transverse tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com