System and method for monitoring motion state of construction vertical shaft sinking bucket

A motion state and monitoring system technology, applied in transportation and packaging, lifting equipment in mines, elevators, etc., can solve problems such as inability to monitor the motion state of buckets, achieve high reliability and automation, ensure safe operation, and ensure real-time sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

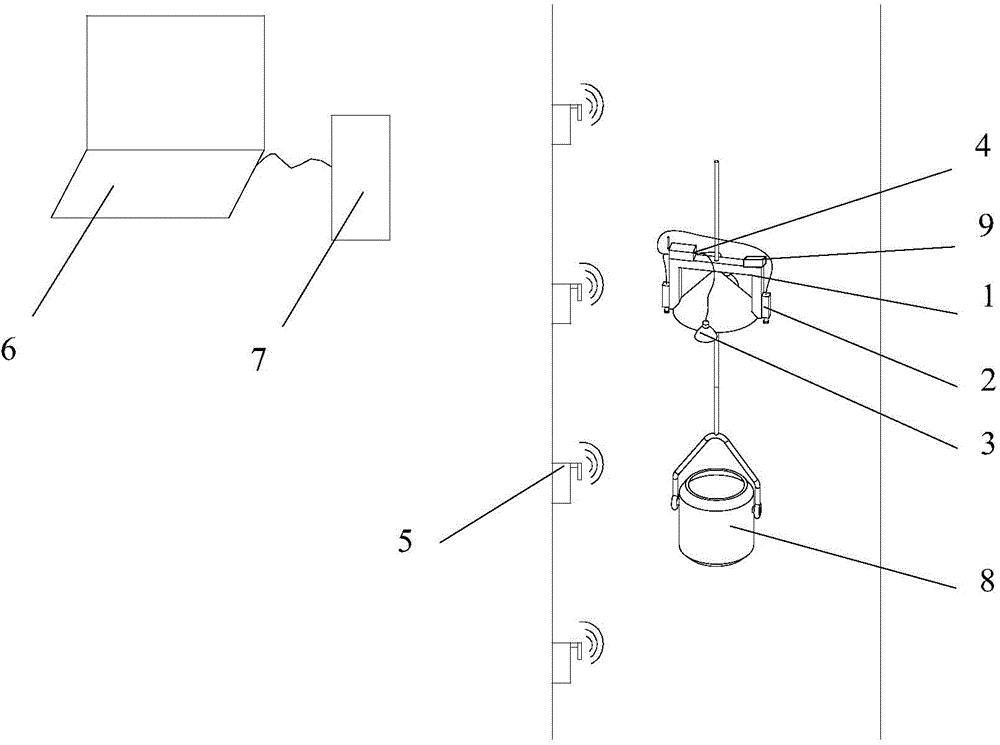

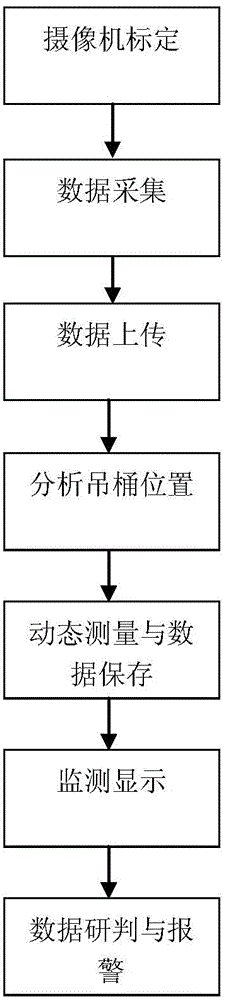

[0030] Example: figure 1 It is the layout diagram of the monitoring system for the movement state of buckets in the construction shaft. The system includes a dynamic signal acquisition and transmission system installed on the carriage 1, a wireless signal transmission system installed on the shaft wall, and a computer centralized control center installed in the control room.

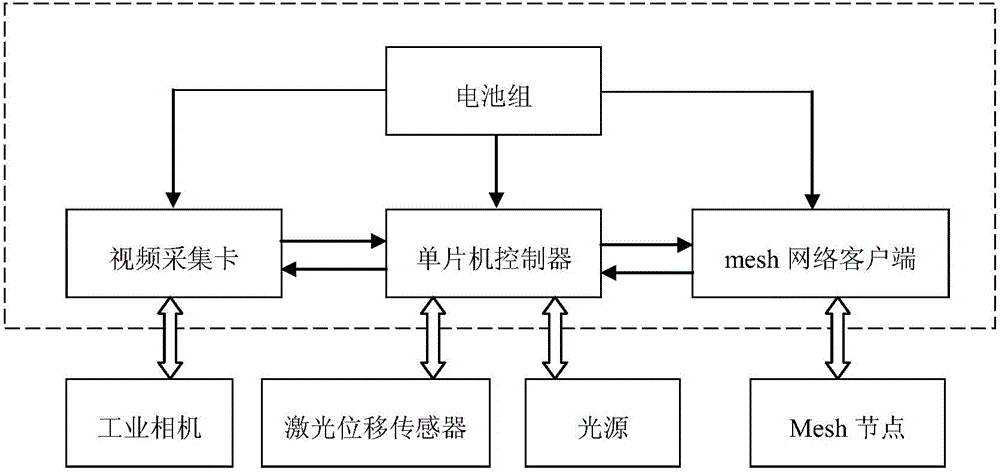

[0031] The dynamic signal acquisition and transmission system includes a laser displacement sensor 9 installed on the carriage 1, two industrial cameras 2 installed on both sides of the carriage, two groups of light sources 3 for supplementary light, and a camera placed on the carriage 1. The terminal acquisition and emission controller 4 is connected with the industrial camera 2, the light source 3 and the laser displacement sensor 9.

[0032] There are two laser displacement sensors 9, two laser displacement sensors 9 are horizontally arranged on the carriage, and the measurement directions of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com