Surface beautified glass tempering resisting method

A glass and steel-resistant technology is applied in the field of a method for surface beautification of glass and tempering resistance, which can solve the problems of inability to withstand tempering, lack of efficiency, and inability to reduce processing costs, and achieve increased life, glass safety, and ideal beautification effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

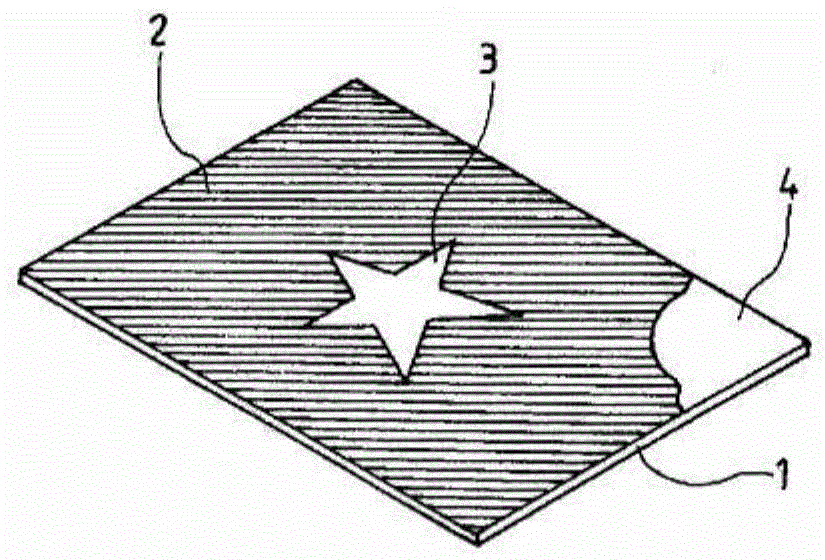

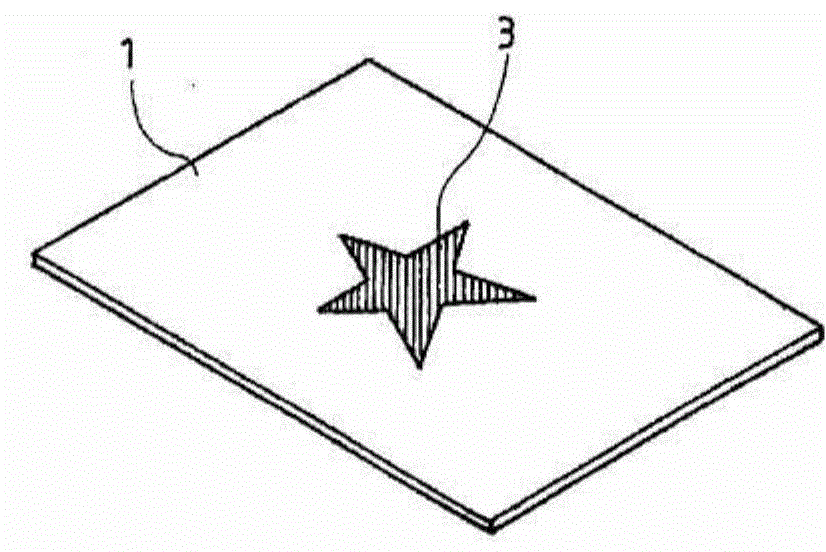

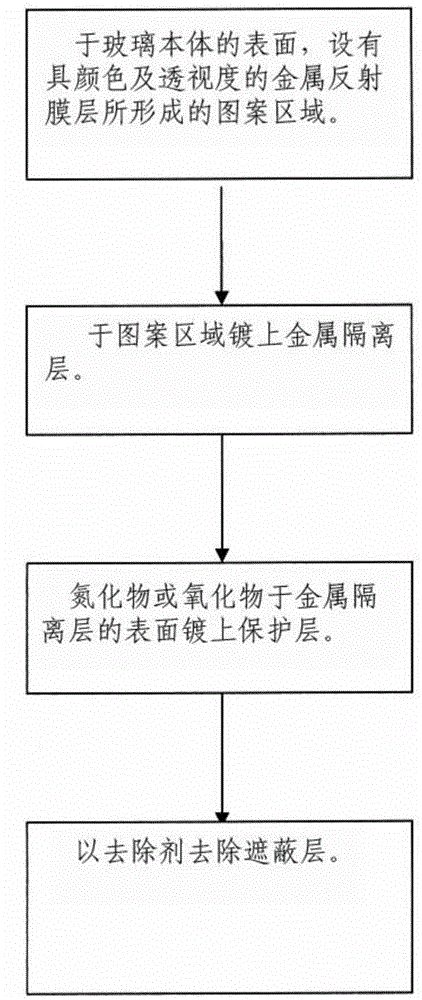

[0022] Please also see image 3 and Figure 4 , and with Figure 5 , is a flow chart of the present invention and a perspective view and a cross-sectional view of plating a metal isolation layer and a protective layer. As shown in the figure, the present invention is as figure 1 and figure 2 As shown, the beautified glass process includes:

[0023] 1. On the non-pattern area 2 on the surface of the glass body 1, a masking layer is provided by screen printing with acid-resistant ink or by developing ink.

[0024] 2. By means of vacuum magnetron sputtering, the unmasked pattern area 3 on the surface of the glass body 1 is coated with a metal reflective film layer with color and transparency.

[0025] 3. Use the remover 4 (alkaline solvent) to remove the shielding layer to leave the pattern area 3 formed by the metal reflective film layer on the surface of the glass body 1 .

[0026] Among them, in order to prevent the pattern area 3 on the surface of the glass body 1 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com