Strip-shaped spreadlight lens and LED strip light

A technology of LED strip light and polarized lens, applied in the direction of light source, electric light source, point light source, etc., can solve the problems of poor visual experience, uneven light distribution, etc., to achieve uniform illumination and enhance the effect of concentrating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in further detail below based on the drawings. It should be understood that the description of the embodiments of the present invention herein is not intended to limit the protection scope of the present invention.

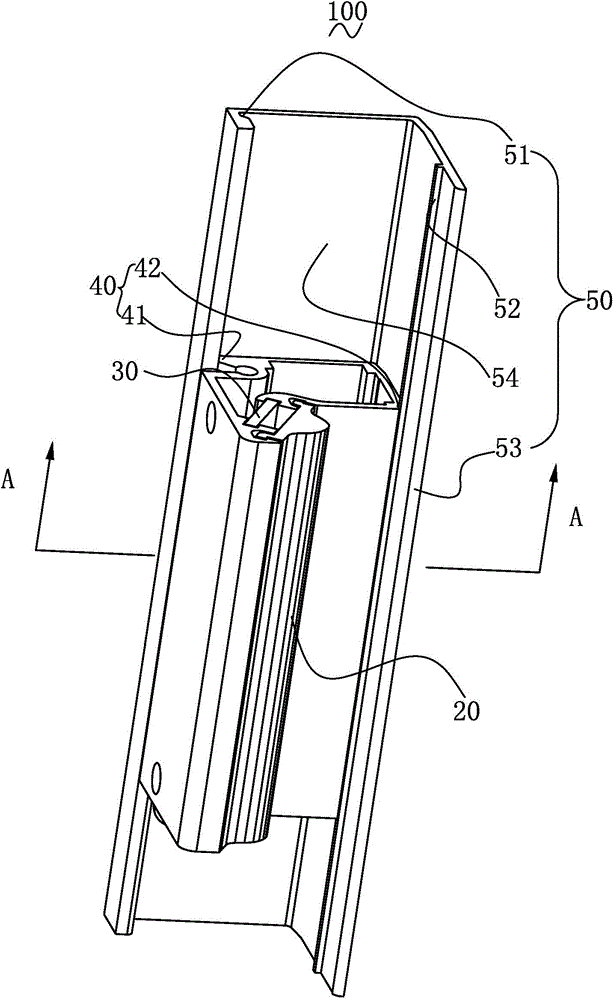

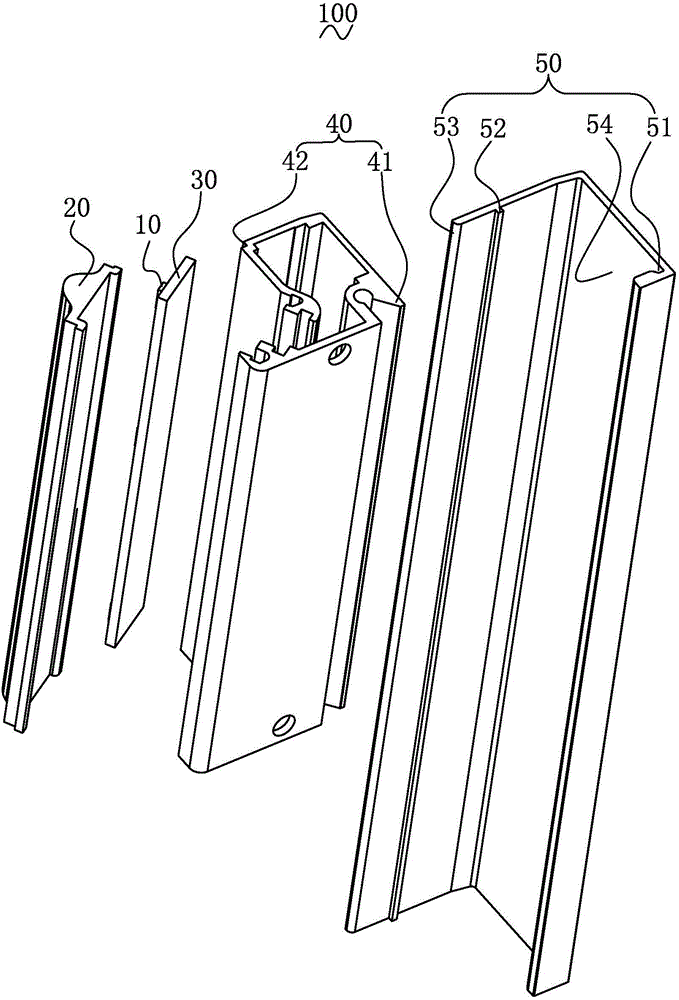

[0015] See figure 1 and figure 2 , Which is a schematic structural diagram and a three-dimensional exploded view of an LED strip light 100 provided by the present invention. The LED strip light 100 includes at least one LED 10, a strip polarizing lens 20 matched with the LED 10, a circuit board 30 for setting the LED 10, a lamp holder 40 for setting the circuit board 30, and A lamp holder 50 for clamping the lamp holder 40. It is conceivable that the LED strip light 100 also includes a power supply for driving the LED 10, which is not the focus of the present invention, and will not be repeated here.

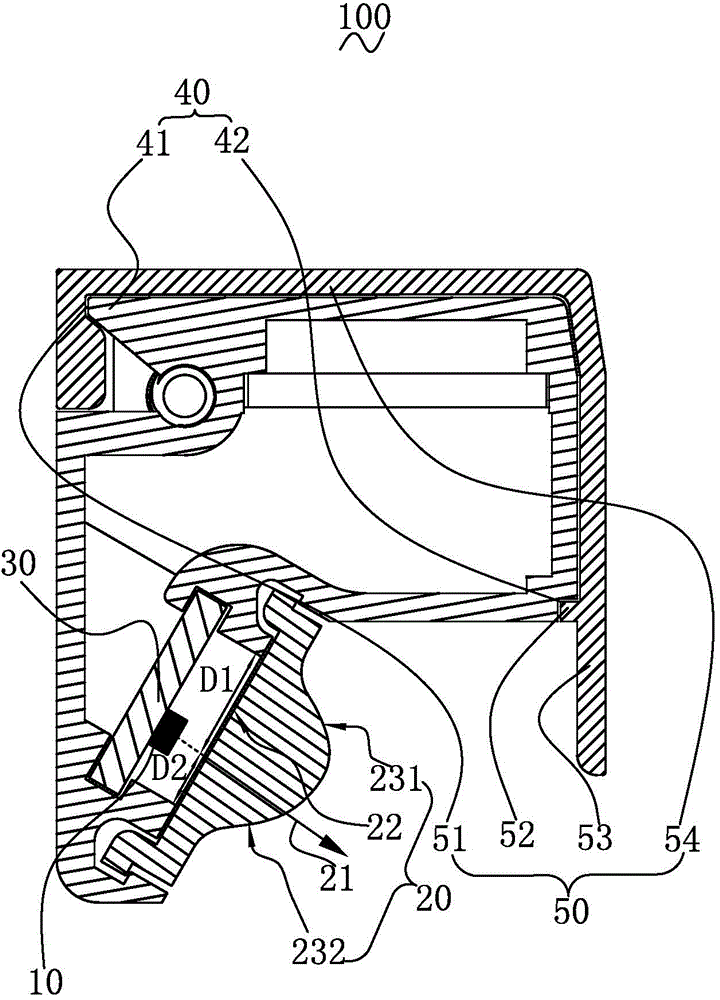

[0016] Please refer to image 3 The LED 10 serves as the light source of the LED strip light 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com