Apparatus and method for overcoming hydrostatic level gauge static friction force and improving precision

A technology of static level and static friction, which is applied in the direction of measuring devices, hydrostatic leveling, instruments, etc. It can solve the problem of easy contact between the float and the liquid storage tank, hindering the normal floating or sinking of the float, and the jamming of the connecting rod and the displacement gauge. To avoid problems such as death, to achieve the effect of simple structure, improved measurement accuracy, and stable driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following description.

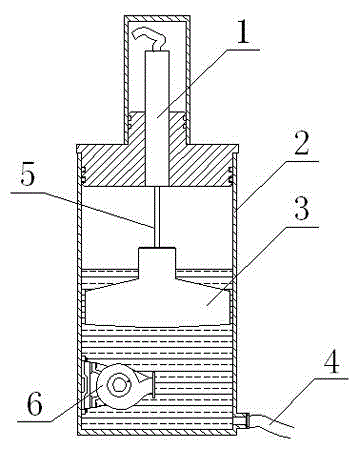

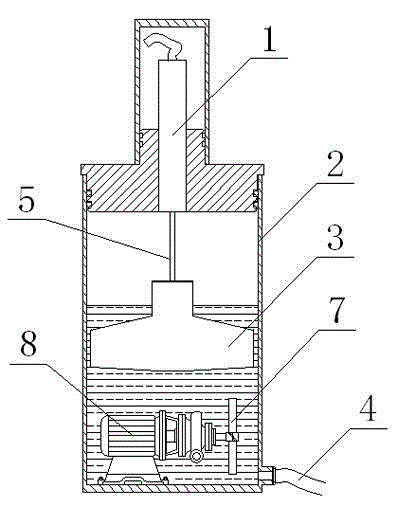

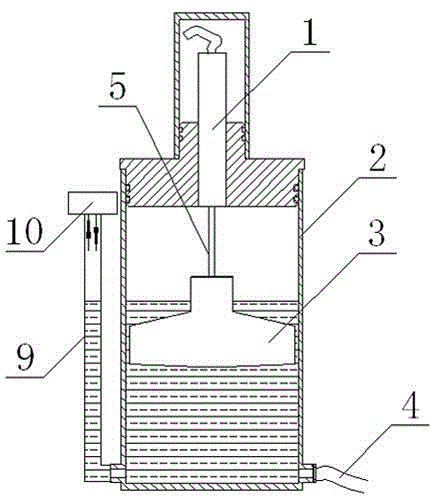

[0032] A device for overcoming the static friction force of a static level to improve accuracy, the static level includes a displacement gauge 1, a liquid storage tank 2 and a float 3, the displacement gauge is fixedly installed on the upper part of the liquid storage tank 2 through a displacement gauge mounting seat, and the storage The bottom of the liquid barrel 2 is connected with the liquid pipe 4, and the float 3 is installed on the displacement gauge 1 through the connecting rod 5. The device also includes a power source assembly, which is used to drive the relative movement between the float 3 and the inner wall of the liquid storage tank 2 or between the connecting rod and the displacement gauge to overcome ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com