A PID Parameter Tuning Method for Differential Linear Systems

A differential linear, parameter tuning technology, applied in general control systems, control/regulation systems, instruments, etc., to achieve the effects of strong stability, reduced wear and significant dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with specific embodiments. Based on the premise of the technical solution of the present invention, this embodiment provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

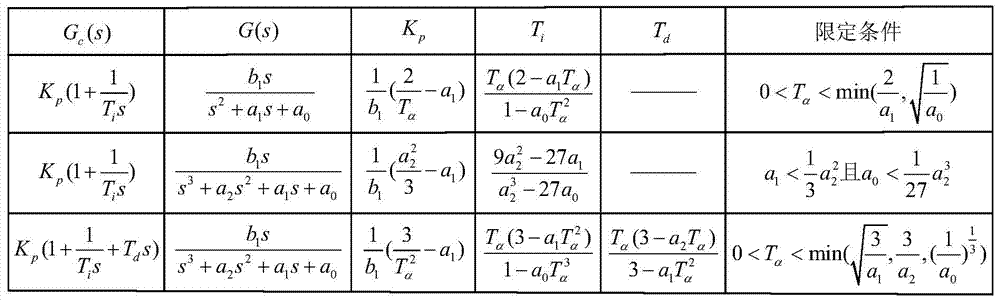

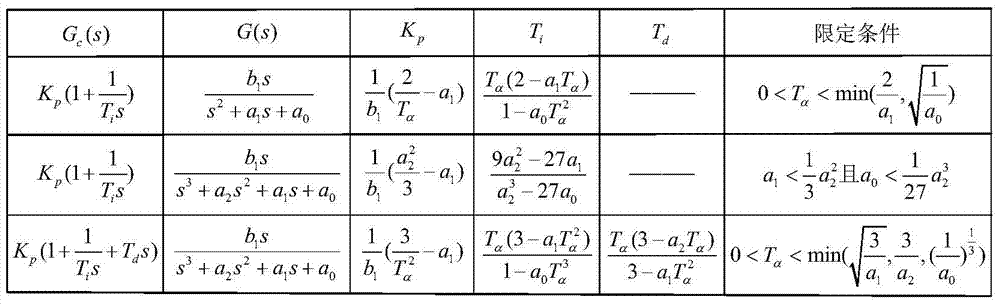

[0024] This embodiment provides a PID parameter tuning method for a differential linear system, which is based on the multi-capacity inertial standard transfer function design. This method is suitable for linear control systems that require fast response and small overshoot, and has strong stability and robustness. High and reduce actuator wear characteristics. The parameter setting table of the PID controller with differential linear system based on the multi-capacity inertia standard transfer function is stored in the data memory and can be used repeatedly.

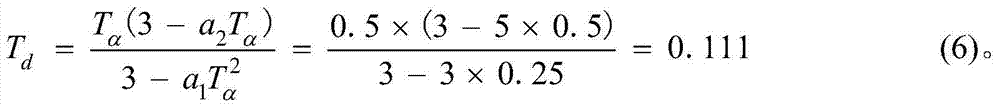

[0025] The parameter tuning table of the above PID controller is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com