An operating mechanism and a locomotive using the operating mechanism

An operating mechanism and operating lever technology, applied in the direction of the power device inside the switch, etc., can solve the problems of unstable closing retention force, reduced closing reliability and stability, and shortened service life of the electromagnetic coil, avoiding the The closing holding force is unstable, improving the reliability and stability, and the effect of closing the holding state is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

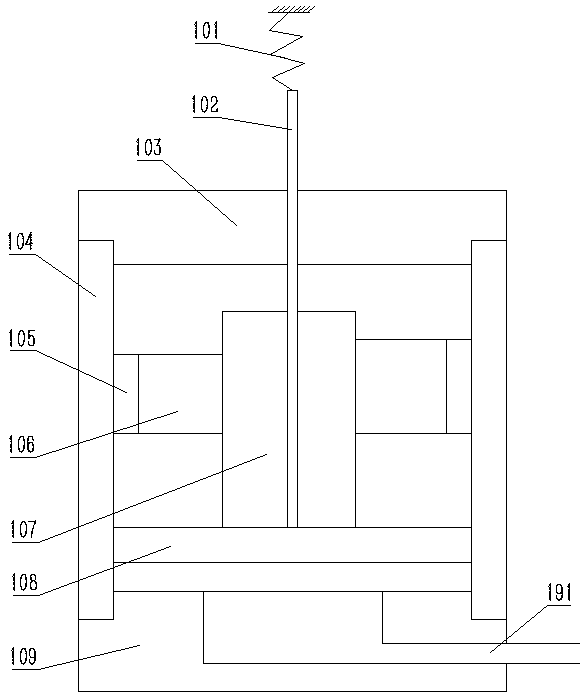

[0023] Embodiment 1 of locomotive among the present invention: as figure 1 As shown, the locomotive includes the locomotive and the operating mechanism assembled on it. The operating mechanism belongs to the field of high-voltage switches, and can be applied not only to the on-board switch control on the locomotive, but also to other operating systems on the car. The operating mechanism includes a cylinder body 104, an upper end cover 103 and a lower end cover 109 fixedly connected to a main cylinder body, the main cylinder body extends along the opening and closing direction, and a piston 108 is installed in the cylinder body 104 to move up and down. The up and down direction is also the opening and closing direction set by the operating mechanism. The piston 108 divides the inner cavity of the main cylinder into an upper closing chamber and a lower opening chamber. At the closing end, the lower end cover 109 is at the opening end of the cylinder body 104 . On the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com