Apparatus and method for processing substrates

A technology of a substrate processing device and a substrate processing method, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem that the chip cannot provide the best exhaust speed, shorten the exhaust time, and prevent the deformation of the chip position , the effect of efficient process processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

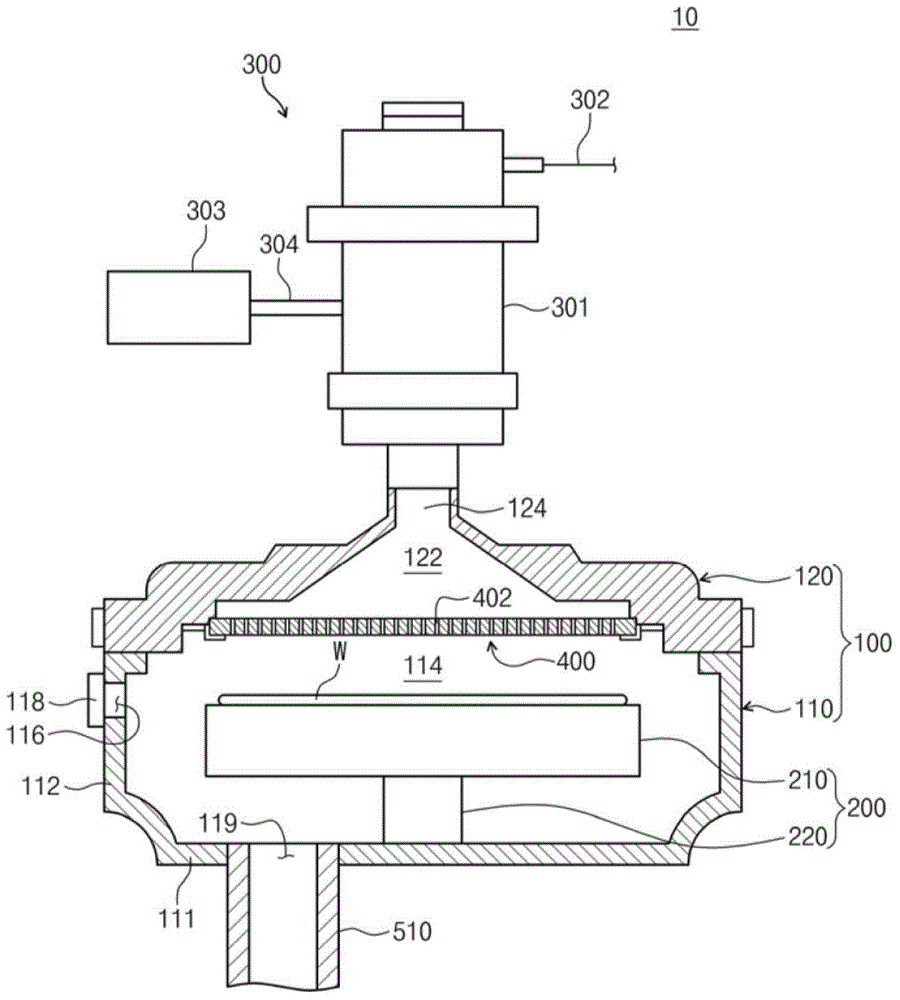

[0091] Refer below with attached Figure 1 With the detailed description of the embodiments, the advantages and features of the present invention and the method for realizing them will be clarified. However, the present invention is not limited to the embodiments disclosed below, and can be embodied in various ways that are different from each other. The embodiments of the present invention are only used to make the disclosure of the present invention more comprehensive, so that those skilled in the art can more completely It is understood that the scope of the present invention is defined only by the scope of the claims. Throughout the specification, the same reference numerals denote the same constituent elements.

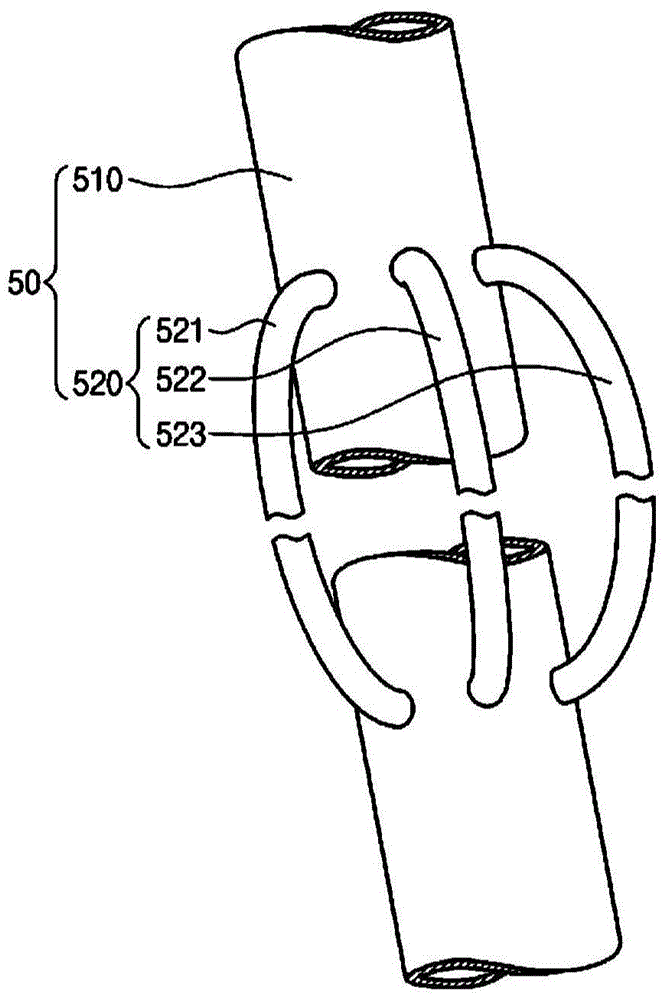

[0092] In an embodiment of the present invention, the size of the fluid passage means that in the plate ( Figure 4 640) is the area where the fluid can flow. In addition, when the board is not provided ( Figure 4 In the case of 640), the size of the fluid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com