Automatic cleaning wafer edge clamping mechanism

A fully automatic cleaning and edge clamping technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effect of facilitating installation and debugging, improving equipment capacity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

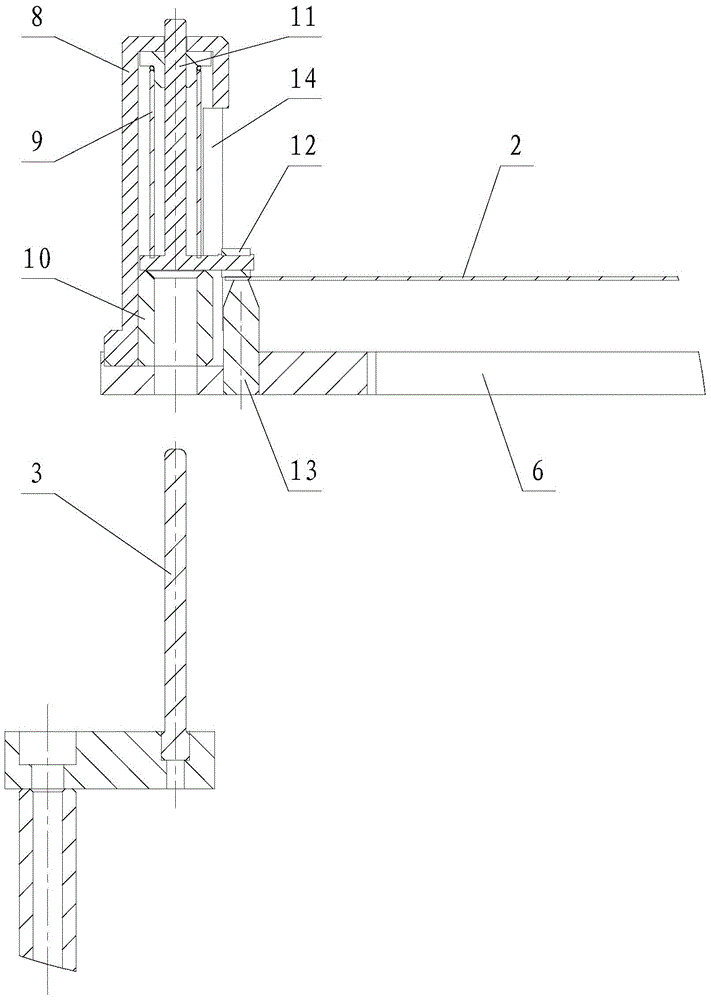

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] The centrifuge unit for fully automatic wafer cleaning includes a wafer holder 6, a spindle motor 7 and a casing, the spindle motor 7 is installed in the casing, the wafer holder 6 is driven to rotate by the spindle motor 7, and the wafer 2 is placed on the wafer holder 6, rotate together with the wafer table 6.

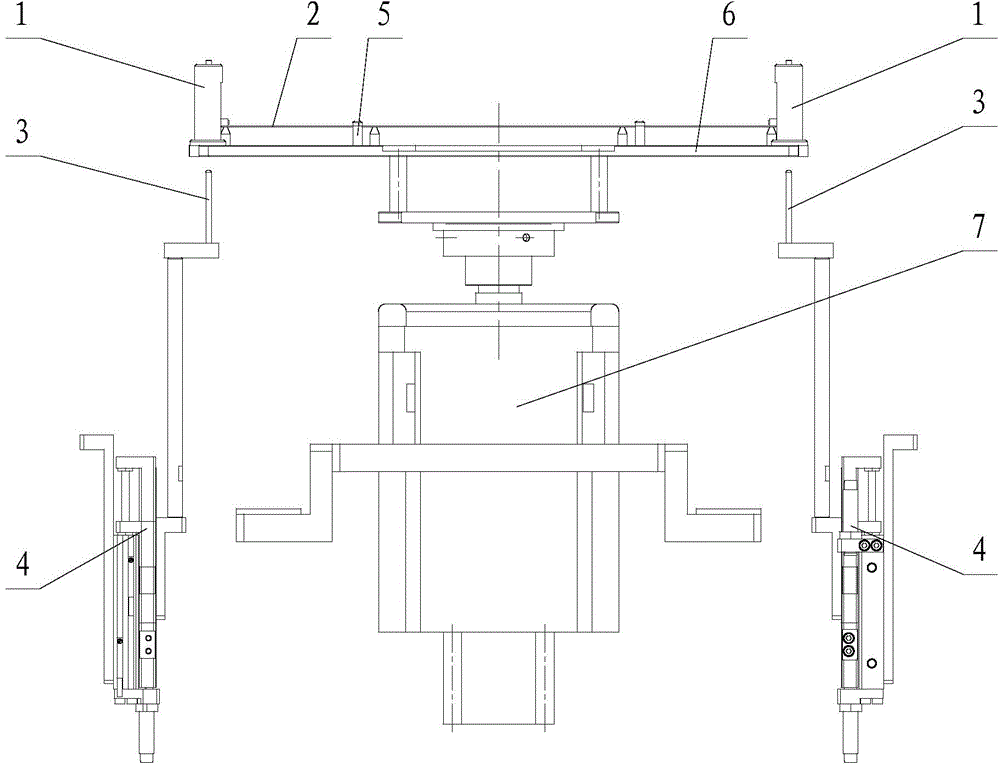

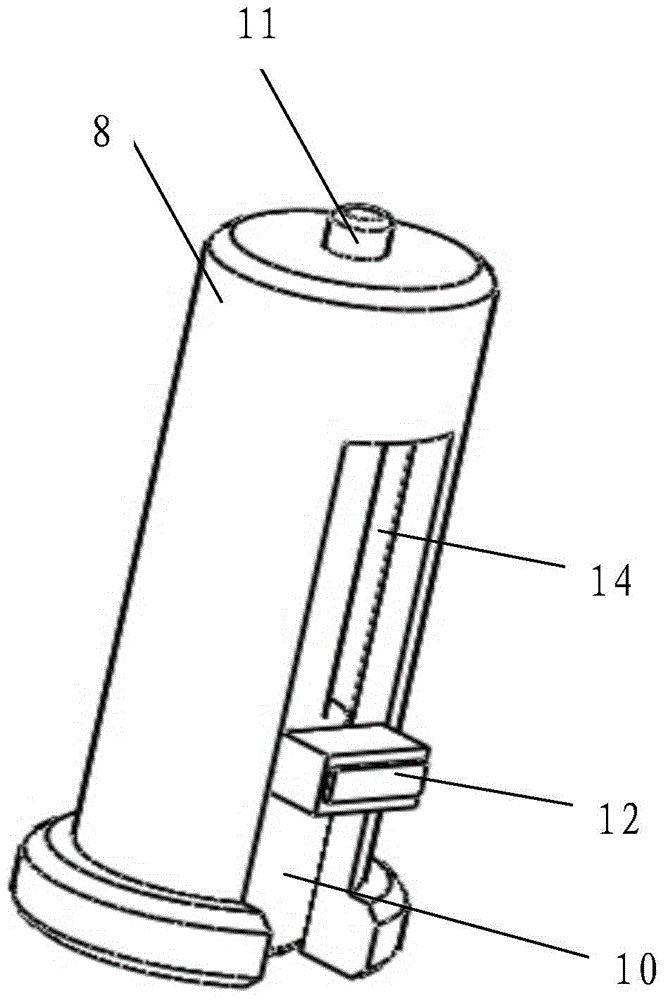

[0017] Such as figure 1 As shown, the present invention includes a gripper 1, a thimble 3 and a lifting cylinder 4, and on the edge of the wafer table 6, a plurality of grippers 1 are evenly distributed along the circumferential direction (the gripper 1 of this embodiment is two ), each holder 1 rotates with the wafer stage 6 . The number of lifting cylinders 4 equal to the number of holders 1 is installed outside the casing, that is, there is a lifting cylinder 4 fixed on the outer surface of the casing directly under each holder 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com