Movable rollover-type mixer truck

A technology of mixer truck and mixing drum, applied in cement mixing device, clay preparation device, unloading device, etc., can solve the problems of inability to mix concrete on construction site, limit development and application, affect construction efficiency, etc. Simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

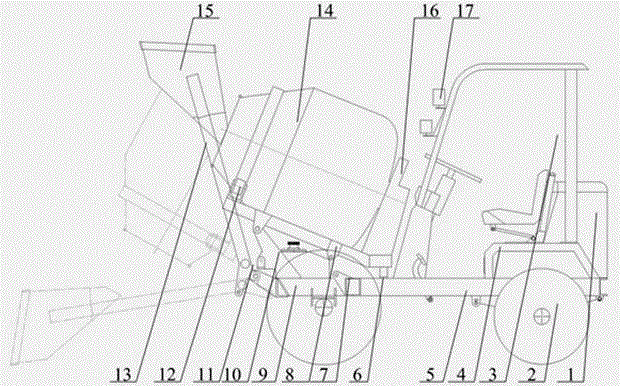

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] like figure 1 As shown, the mobile tipping mixer truck of the present invention includes a front chassis 9, a rear chassis 6, a mixing drum 14, a mixing drum driving mechanism 17, a shovel 15, a driving control unit 3, a hydraulic unit 2, an engine 1 and wheels 2. The front underframe 9 and the rear underframe 6 are hinged through the swing bridge 7 to form a swing frame structure, so as to provide better balance during operation and improve the running stability of the mixer truck. Four wheels 2 are connected on the front underframe 9 and the rear underframe 6 respectively. The third hydraulic jack (not shown in the figure) is connected between the front chassis 9 and the rear chassis 6, and the third hydraulic jack is connected to the hydraulic unit 2. Through the third hydraulic jack, mixing or discharging can be carried out when the mixer truck i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com