Multi-concave-plane propeller

A propeller, concave technology, used in propellers, rotating propellers, rotary propellers, etc., can solve problems such as not being widely promoted, and achieve the effect of reducing radial flow and high propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

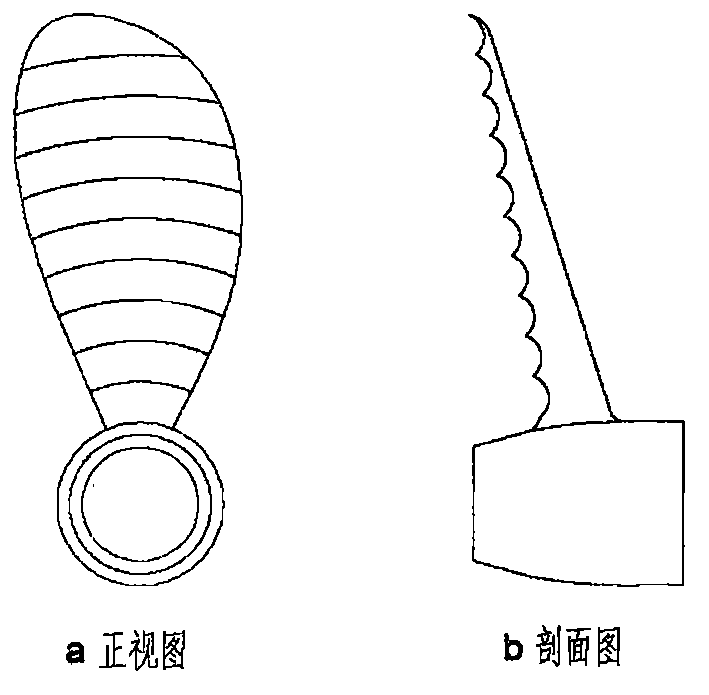

[0018] Specific implementation mode 1, such as figure 1 As shown, the propeller blade is airfoil or bow-shaped, and the thrust surface of the blade is composed of multiple concave surfaces in the radial direction. The cross-section of each concave surface is arc-shaped, with equal depth and equal width.

specific Embodiment approach 2

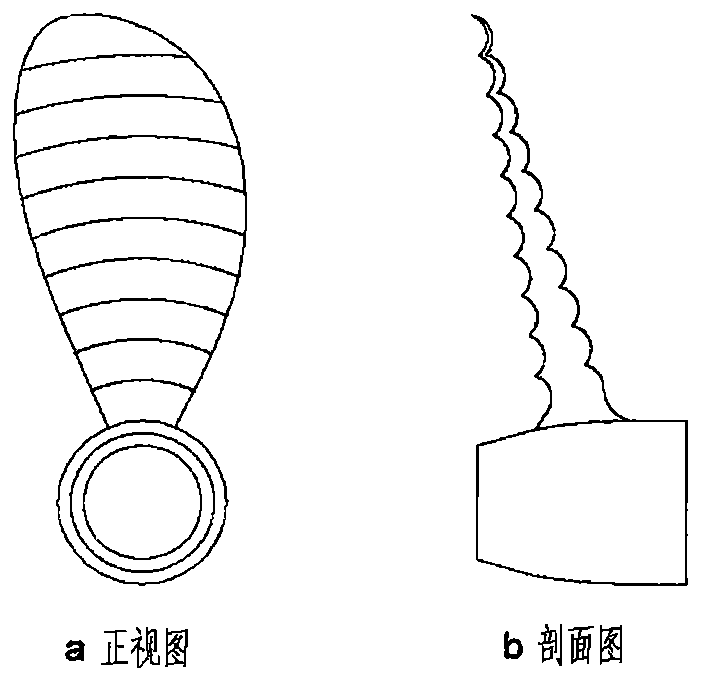

[0019] Specific implementation mode 2, such as figure 2 As shown, the propeller blade is airfoil or bow-shaped, and the thrust surface of the blade is composed of multiple concave surfaces in the radial direction. The concave and convex positions of the suction surface correspond to the thrust surface, and the concave grooves corresponding to the suction surface also form concentric circles.

specific Embodiment approach 3

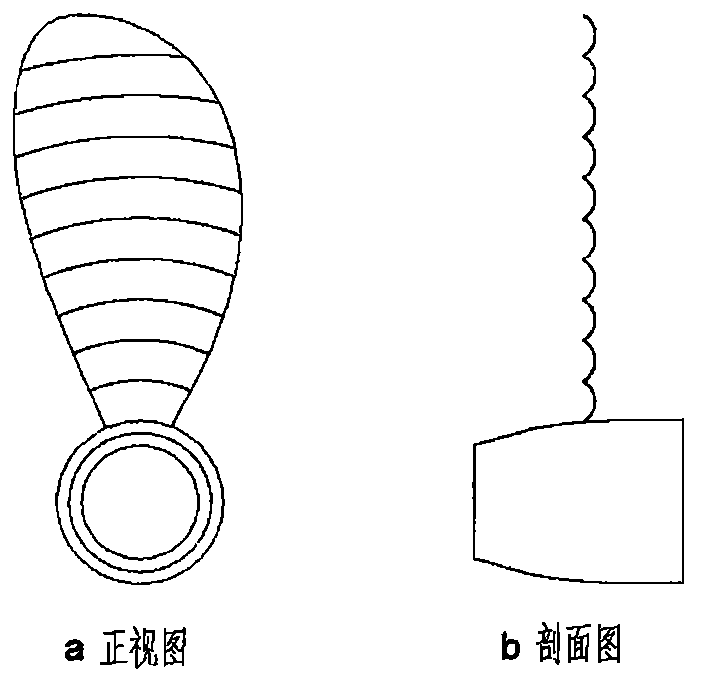

[0020] Specific implementation mode 3, such as image 3 As shown, the propeller blade is a sheet type, and the blade body is composed of multiple concave surfaces in the radial direction. The cross-section of each concave surface is arc-shaped, with equal depth and equal width, and each concave surface forms a concentric circle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com