An aircraft assembly work dock

A technology for aircraft assembly and work, applied in aircraft assembly, aircraft parts, ground installations, etc., can solve problems such as unsightly appearance, limited space for plant use, and unfavorable aircraft production costs, achieve a novel overall design concept, and improve space utilization. efficiency, easy inspection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

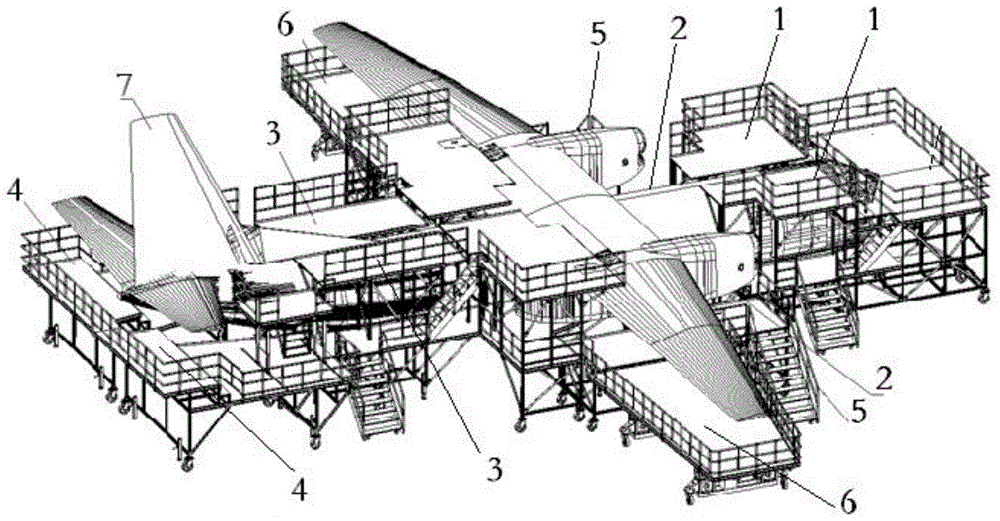

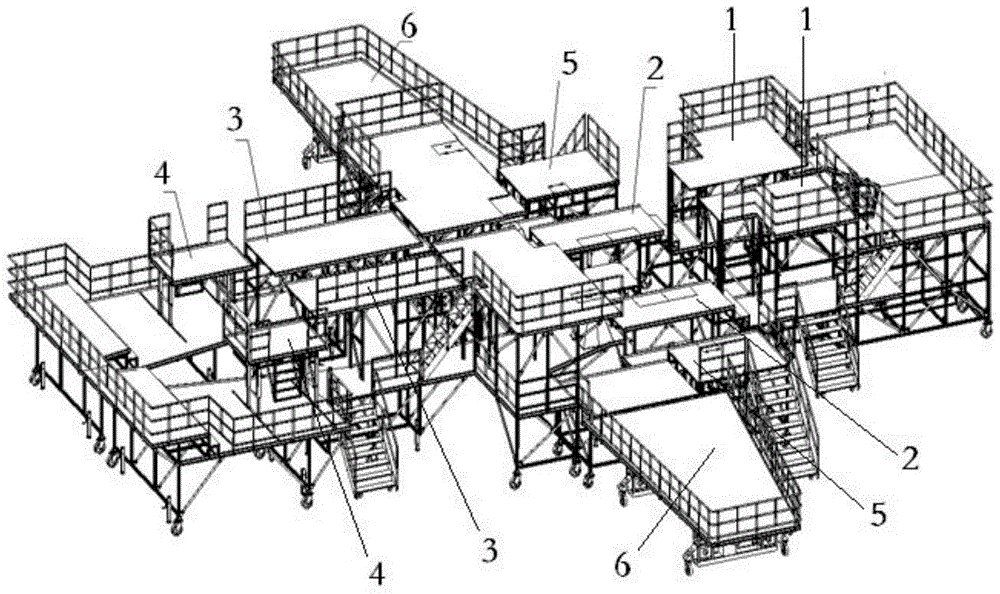

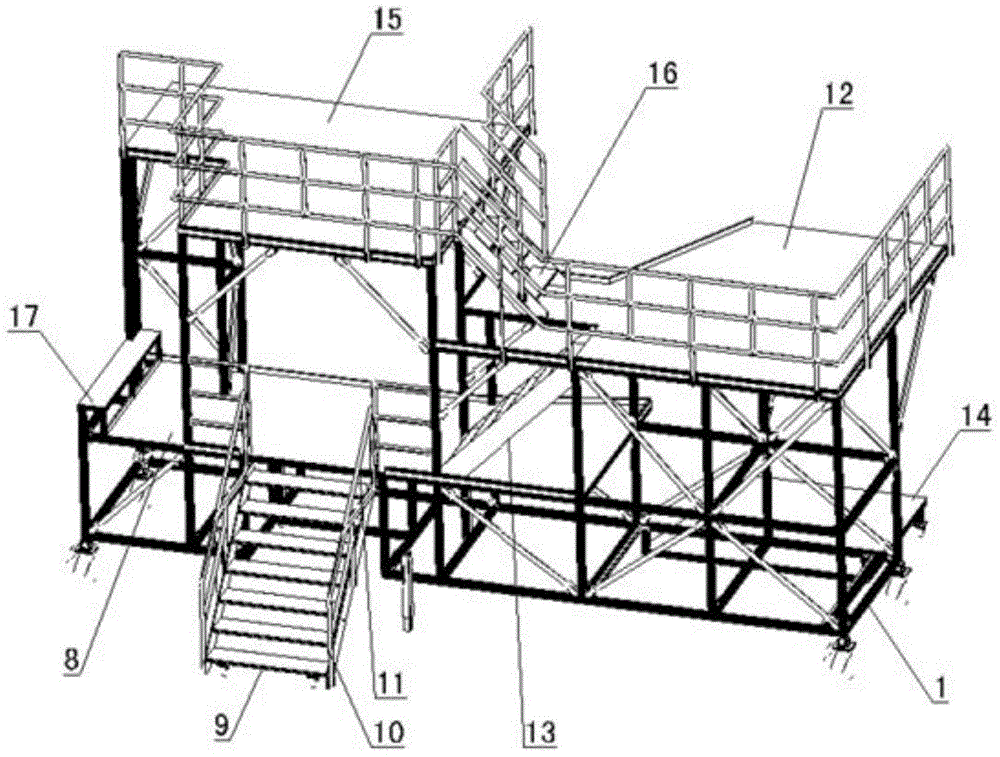

[0033] see figure 1 , an aircraft assembly work dock, which is a combined modular assembly platform, and each module is divided into six groups of modules according to the degree of concentration of operations, and each group has a symmetrical structure, which are respectively: two fuselage front section modules 1 (see image 3 ), two front wing body modules 2 (see Figure 5 ), two rear wing modules 3 (see Figure 7 ), two empennage modules 4 (see Figure 9 ), two nacelle outer modules 5 (see Figure 11 ), two wing modules 6 (see Figure 13 ). The six groups of modules of the aircraft assembly work dock are symmetrically distributed on both sides of the aircraft body 7 according to the shape of the aircraft, and there are twelve modules in total. Each module contains an independent support frame, working platform, movable casters and fixed feet. The modules are combined to form multiple interpenetrating working platforms that can approach the external working parts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com