Spraying washing machine having sealed power supply structure

A jet type, washing machine technology, which is applied to washing machines with containers, other washing machines, washing devices, etc., can solve the problems of poor sealing, electric leakage and injury, large water flow velocity, etc., and achieves good sealing, simple structure, and easy manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

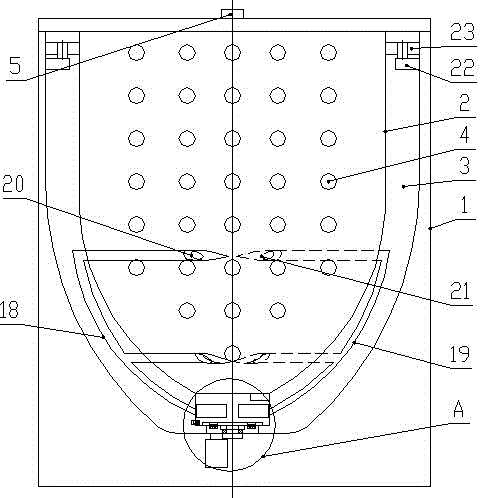

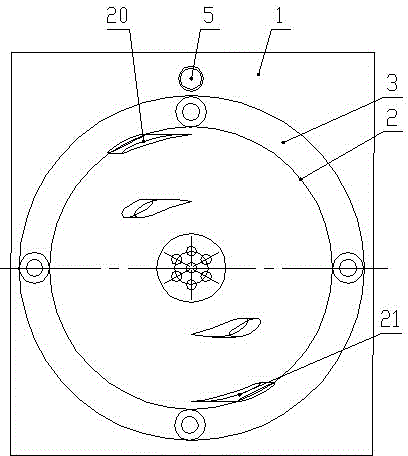

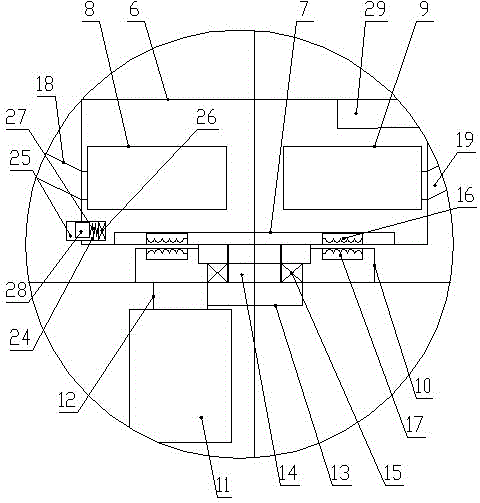

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the jet-flow washing machine with a sealed power supply structure includes an outer cylinder 1 and an inner cylinder 2 disposed inside the outer cylinder 1. There is a gap 3 between the inner side wall of the outer cylinder 1 and the outer side wall of the inner cylinder 2. The side of the inner cylinder 2 is uniformly provided with water permeable holes 4, the top of the outer cylinder 1 is provided with a water inlet pipe 5, and the bottom of the inner cylinder 2 is fixedly connected with a water tank 6, and the water tank 6 is equipped with a wireless signal receiver 29 and an upper sealing box 7 And the positive rotation water pump 8 and the reverse rotation water pump 9 positioned in the upper sealing box 7, the bottom of the outer cylinder 1 is provided with a lower sealing box 10, a motor 11, a driving gear 12, a driven gear 13 and a drive shaft 14, and the driving gear 12 is installed On the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com