Back bolt and connection structure

A back-bolt and consistent technology, which is applied to building components, building structures, coverings/linings, etc., can solve the problems of flakes that cannot be pulled out, slipped out, and high manufacturing costs of conjoined cylindrical expansion parts, and achieve strong earthquake resistance, good fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

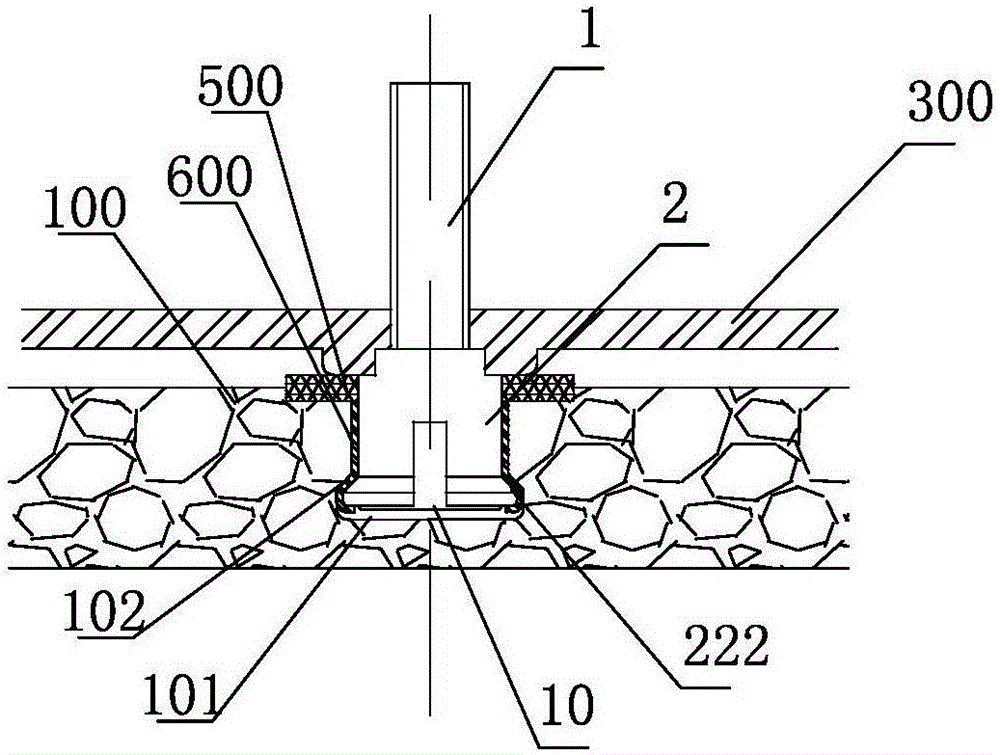

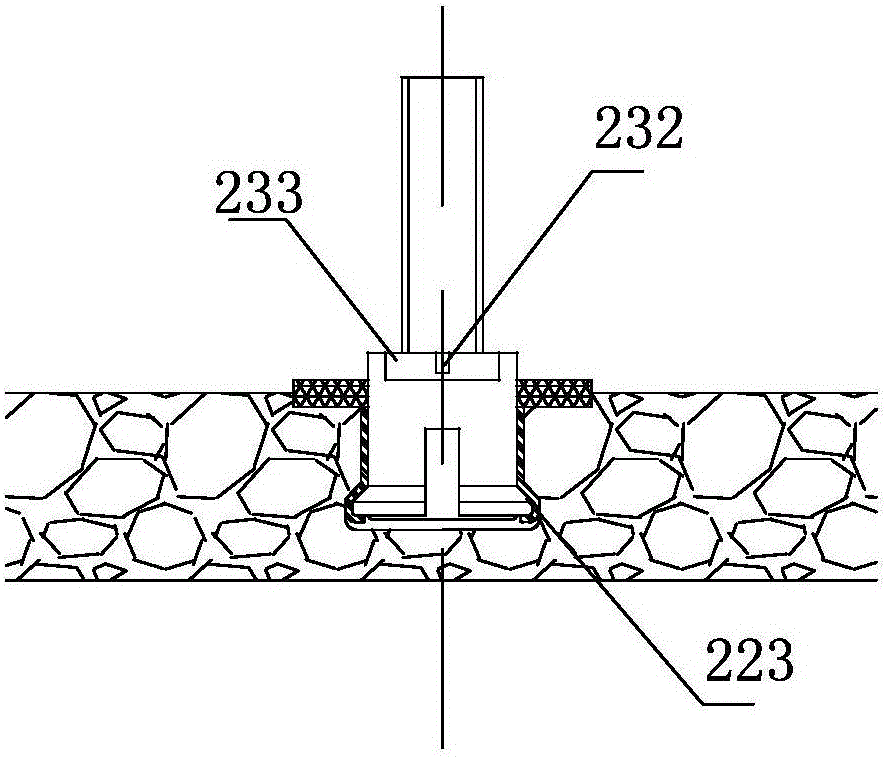

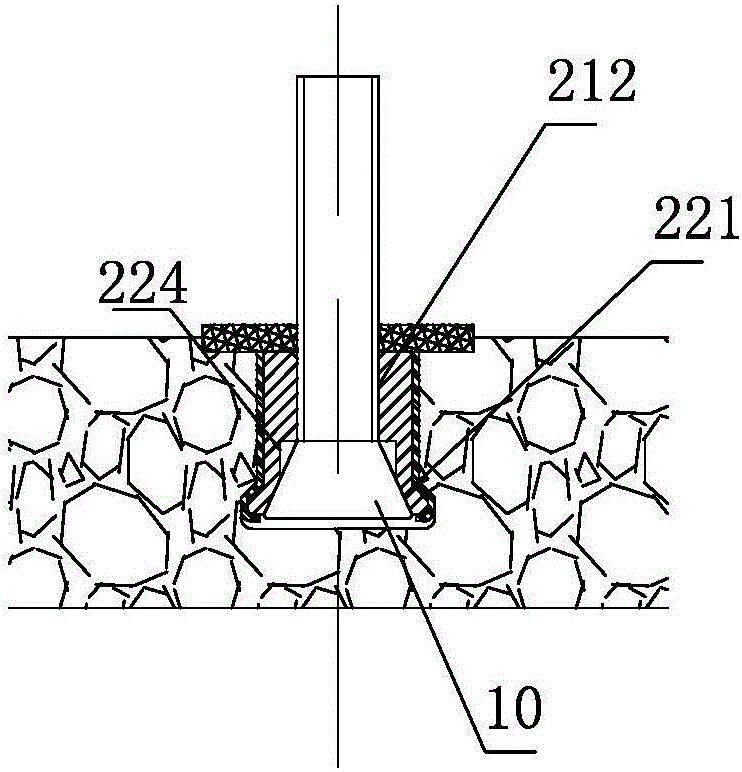

[0038] Refer to attached Figure 1-5 . The stress-free position-limiting back bolt provided by the present invention includes an anchor rod 1 with a cone head 10 and an expansion element 2. The expansion element has a cylindrical body 21 and a plurality of expansion locations 22 at one end of the cylindrical body.

[0039] The expansion part 22 can be in the shape of a circular arc sheet. The inner side of the expansion part has a force receiving part 221 matching with the cone head 10 , and the force receiving part 221 can adopt an inner conical surface matching with the cone head 10 . The expansion element 2 is sleeved on the anchor rod 1 , and the cone head 10 of the anchor rod is stuck by the expansion part 22 and cannot pass through the expansion element 2 .

[0040] The outer diameter of the expansion part 22 is consistent with the outer diameter of the cylindrical main body 21, that is, after being expanded, the expansion part 22 is fully expanded outwards, and is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com