A test device and method for filling slurry delivery

A technology of filling slurry and testing equipment, which is applied in the field of pipeline transportation engineering and fluid mechanics, can solve the problems of affecting the accuracy of test results, increasing the measurement time, and high labor intensity, and achieves convenient and accurate rheological parameters, simple processing, and production convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

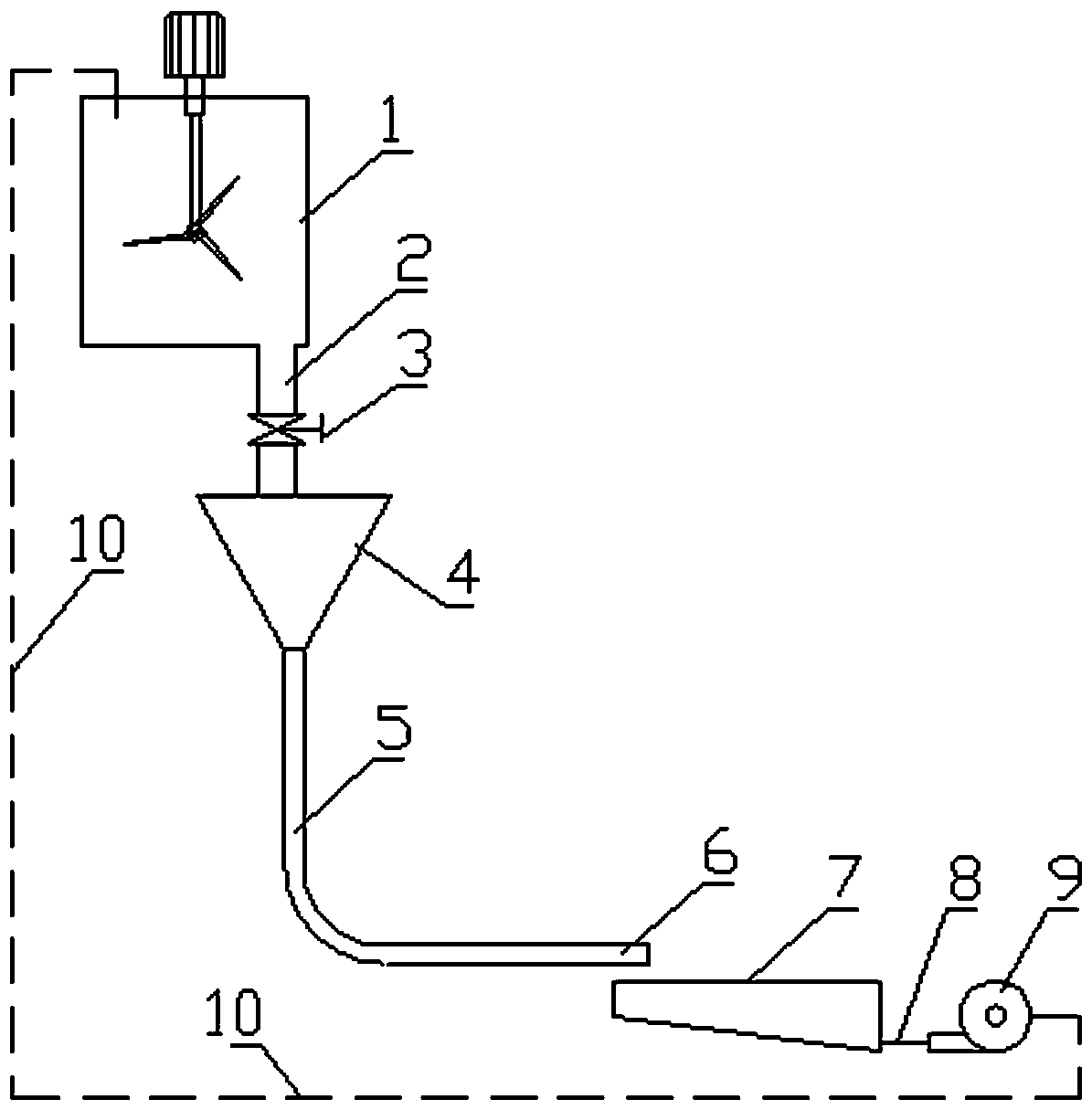

[0023] refer to figure 1 , the present embodiment comprises a mixing tank 1, a storage bin 4, a discharge pipe 5, a receiving tank 7, a small sand pump 9 and a feeding pipe 10, the mixing tank 1 is provided with an agitator, and the lower end of the mixing tank 1 is provided with There is a discharge pipe 2, the end of the discharge pipe 2 is equipped with a discharge valve 3, the storage bin 4 is placed under the discharge pipe 2, the lower end of the storage bin is connected with one end of the discharge pipe 5, and the other end of the discharge pipe 5 It is the discharge nozzle 6, and the discharge nozzle 6 is placed above the material receiving tank 7. The material receiving tank 7 is connected to the small sand pump 9 through the connecting pipe 8, and the small sand pump 9 is connected to the mixing tank 1 through the return pipe 10. connected.

[0024] The mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com