A method and device for measuring sediment denitrification rate

A technology for measuring devices and measuring methods, applied in measuring devices, electrochemical variables of materials, instruments, etc., can solve the problems of overestimation and underestimation of denitrification rate, etc., and achieve the effects of ensuring timeliness, easy disassembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

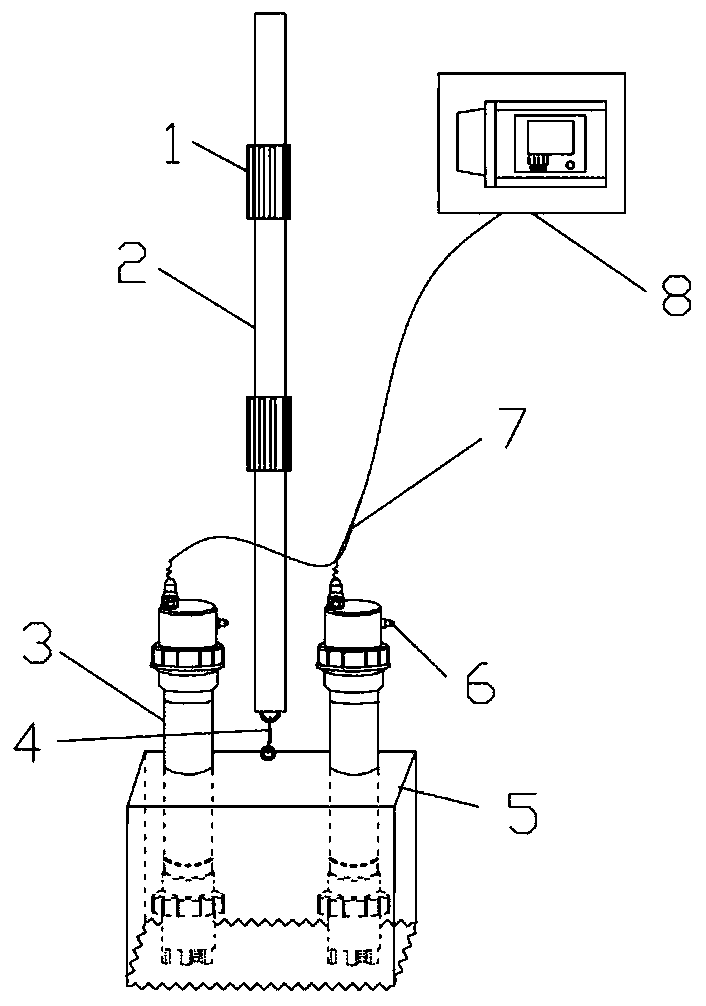

[0076] Embodiment 1: The present invention measures the denitrification rate of a certain natural river sediment in Shanghai

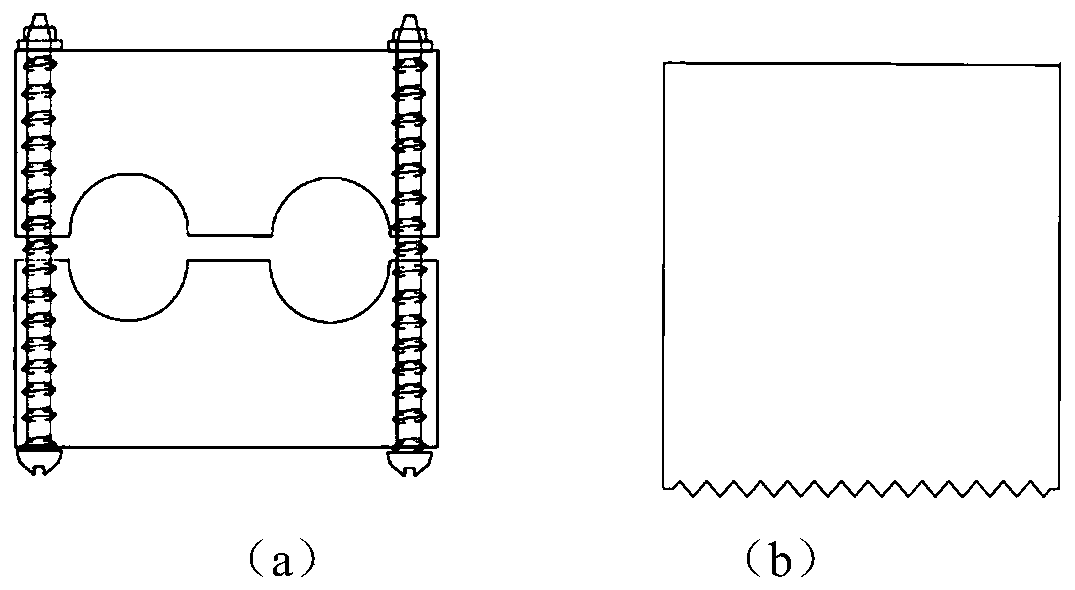

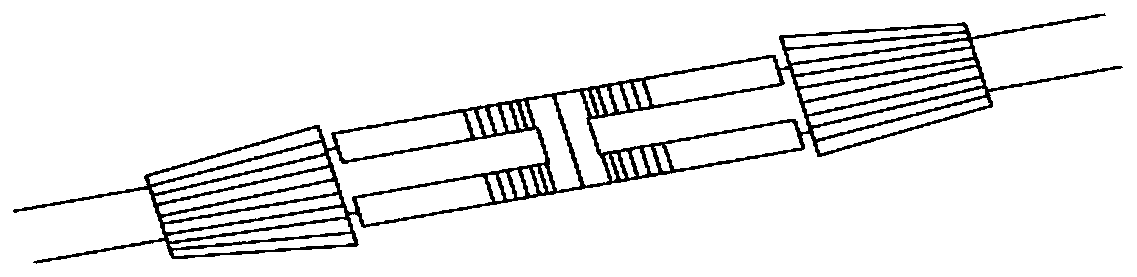

[0077]First put the fixed shell on the outside of the sensor 3, the telescopic rod 2 is connected to the fixed shell 5 through the fixed interface of the telescopic rod 4, connect the ammonia nitrogen sensor and the nitrate nitrogen sensor to the Liquiline CM442 transmitter (the sensor model selects digital sensor CAS40D), Fix the transmitter 8 at a position convenient for reading, and ensure the stability of the device through the zigzag-shaped fixed shell. The water depth of the river is 1.8m. Adjust the telescopic rod 2 and lower the sensor 3 according to the height of the sediment thickness from the water surface until the bottom electrode probe is immersed in the sediment for 2-5cm, and adjust the cable laying length accordingly. Turn on the power, press the measurement button, set the denitrification rate measurement time to 120min, and the syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com