Equivalent thermal conductivity measurement method and equipment for wall material

A technology of thermal conductivity and wall material, applied in the field of wall materials, can solve the problems of long detection period, large influence of human and environmental factors, and inability to intuitively reflect the energy-saving effect of samples, so as to achieve shorter detection period, accurate and efficient equivalent Thermal conductivity, the effect of real and effective energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

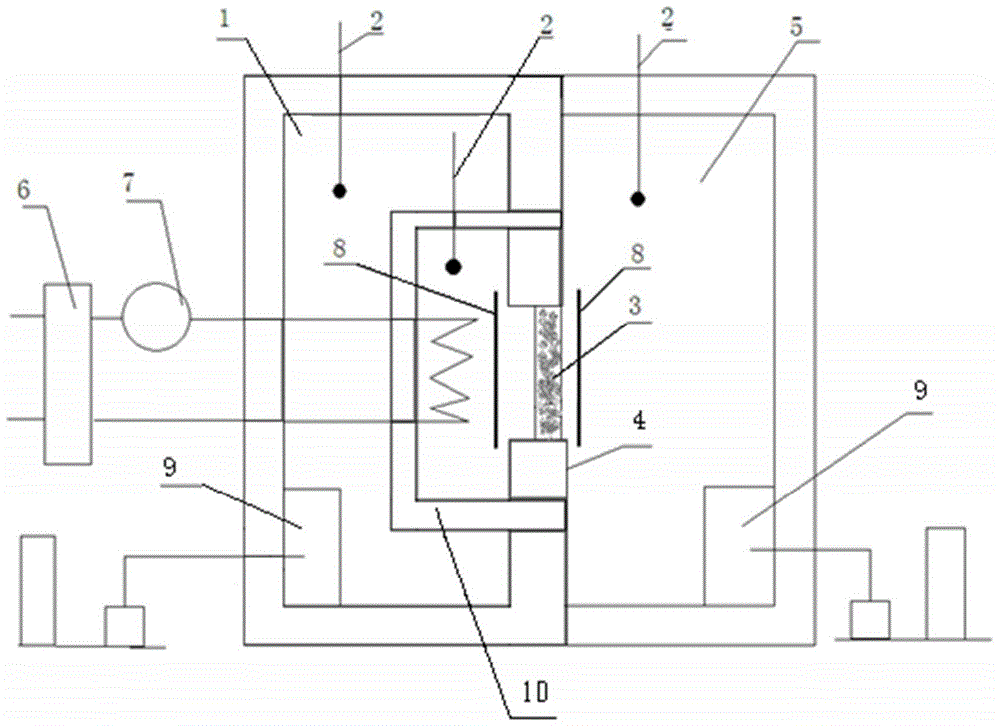

[0054] Prepare a filling body 4 with a known thermal conductivity and a specification of 500mm×500mm×d, where d represents the thickness of the material to be tested in the direction of heat transfer, and the filling body 4 generally chooses a polystyrene board. When the size of the tested piece 3 exceeds 500mm×500mm, it shall be prepared according to 500mm×500mm×d. The material of the tested piece 3 is sintered porous brick or thermal insulation block, etc. When the size of the tested piece 3 is less than 500mm×500mm, A single sample is taken for the test, and the material needs to be dried in advance to a constant quality state.

[0055] The filling body 4 usually selects polystyrene board, and the filling body 4 is installed in the metering box 10 of the wall material equivalent thermal conductivity measuring device of the present invention as the opening of the test area, and the periphery of the filling body 4 is sealed with weather-resistant adhesive, and the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com