Flexible display device and manufacturing method thereof

A manufacturing method and flexible display technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of short service life and poor reliability, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

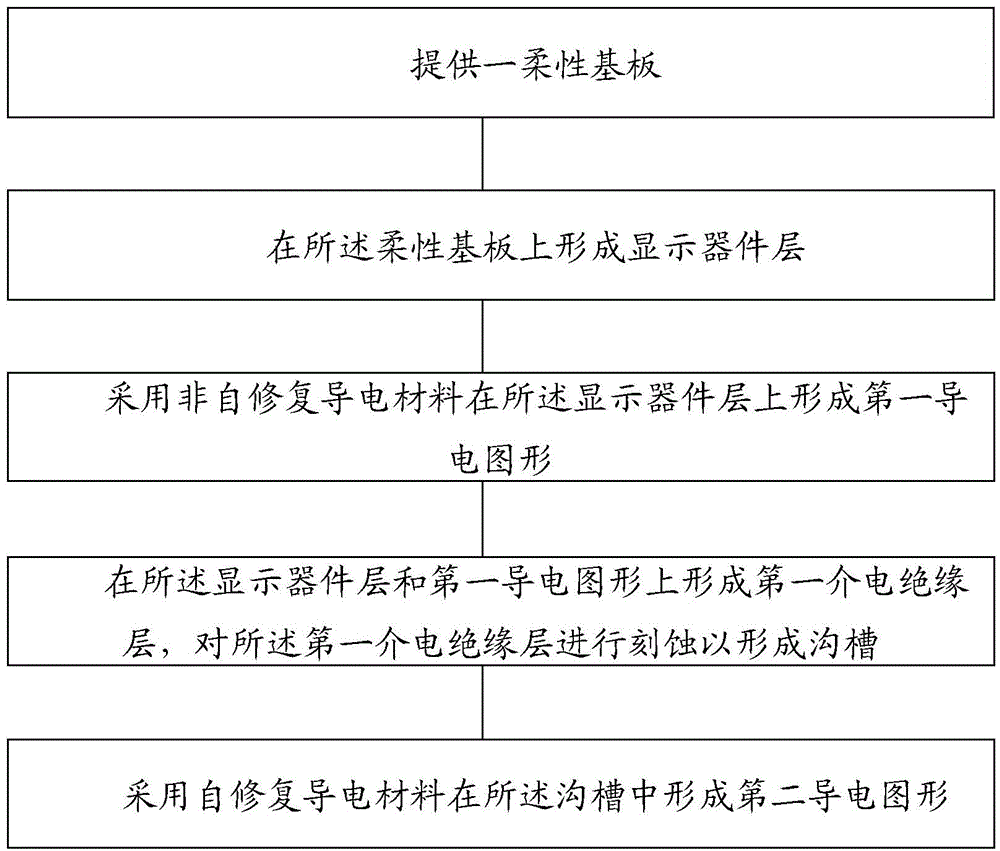

[0065] Please refer to figure 2 , which is a process flow diagram of the method for manufacturing a flexible display device according to Embodiment 1 of the present invention. Such as figure 2 As shown, the manufacturing method of the flexible display device includes:

[0066] Step 1: providing a flexible substrate;

[0067] Step 2: forming a display device layer on the flexible substrate;

[0068] Step 3: forming a first conductive pattern on the display device layer;

[0069] Step 4: forming a first dielectric insulating layer on the display device layer and the first conductive pattern, and etching the first dielectric insulating layer to form grooves;

[0070] Step five: forming a second conductive pattern in the trench;

[0071] Wherein, the first conductive pattern is made of non-self-healing conductive material, and the second conductive pattern is made of self-healing conductive material.

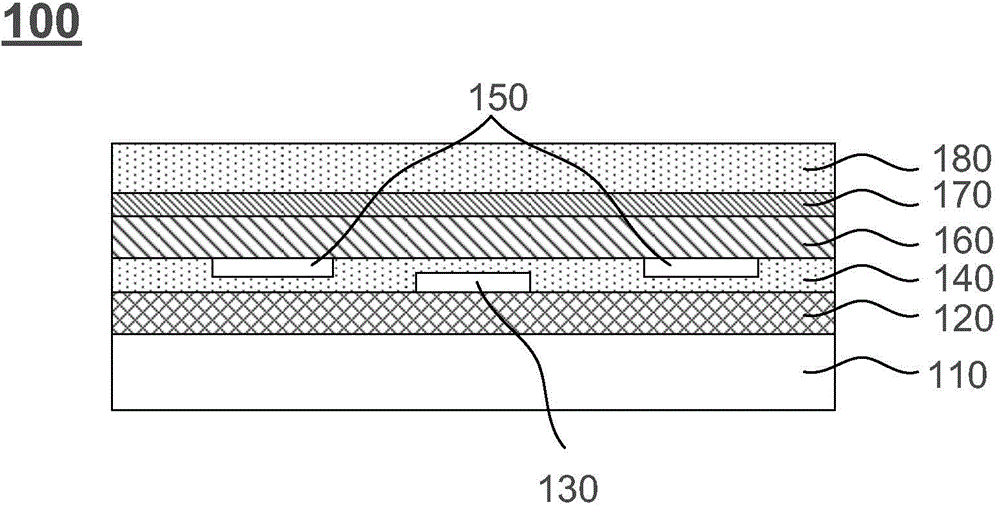

[0072] Below will combine specific embodiment and appended image 3 , ...

Embodiment 2

[0092] Please refer to figure 2 , which is a process flow diagram of the method for manufacturing a flexible display device according to Embodiment 1 of the present invention. Such as figure 2As shown, the manufacturing method of the flexible display device includes:

[0093] Step 1: providing a flexible substrate;

[0094] Step 2: forming a display device layer on the flexible substrate;

[0095] Step 3: forming a first conductive pattern on the display device layer;

[0096] Step 4: forming a first dielectric insulating layer on the display device layer and the first conductive pattern, and etching the first dielectric insulating layer to form grooves;

[0097] Step five: forming a second conductive pattern in the trench;

[0098] Wherein, the first conductive pattern is made of non-self-healing conductive material, and the second conductive pattern is made of self-healing conductive material.

[0099] Specifically, the content of Step 1 to Step 4 in this embodiment ...

Embodiment 3

[0107] Please refer to Figure 4 , which is a process flow diagram of the manufacturing method of the flexible display device according to the third embodiment of the present invention. Such as Figure 4 As shown, the manufacturing method of the flexible display device includes:

[0108] Step 1: providing a flexible substrate;

[0109] Step 2: forming a display device layer on the flexible substrate;

[0110] Step 3: forming a first conductive pattern on the display device layer;

[0111] Step 4: forming a first dielectric insulating layer on the display device layer and the first conductive pattern, and etching the first dielectric insulating layer to form grooves;

[0112] Step five: forming a second conductive pattern in the trench;

[0113] Wherein, the first conductive pattern is made of self-healing conductive material, and the second conductive pattern is made of non-self-healing conductive material.

[0114] Below will combine specific embodiment and appended F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com