Diaphragm pump with a magnetohydrodynamic drive

A magnetic fluid dynamics and diaphragm pump technology, applied to pumps with flexible working elements, pumps, engine elements, etc., can solve the problems of inability to provide instantaneous flow rate measurement function, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

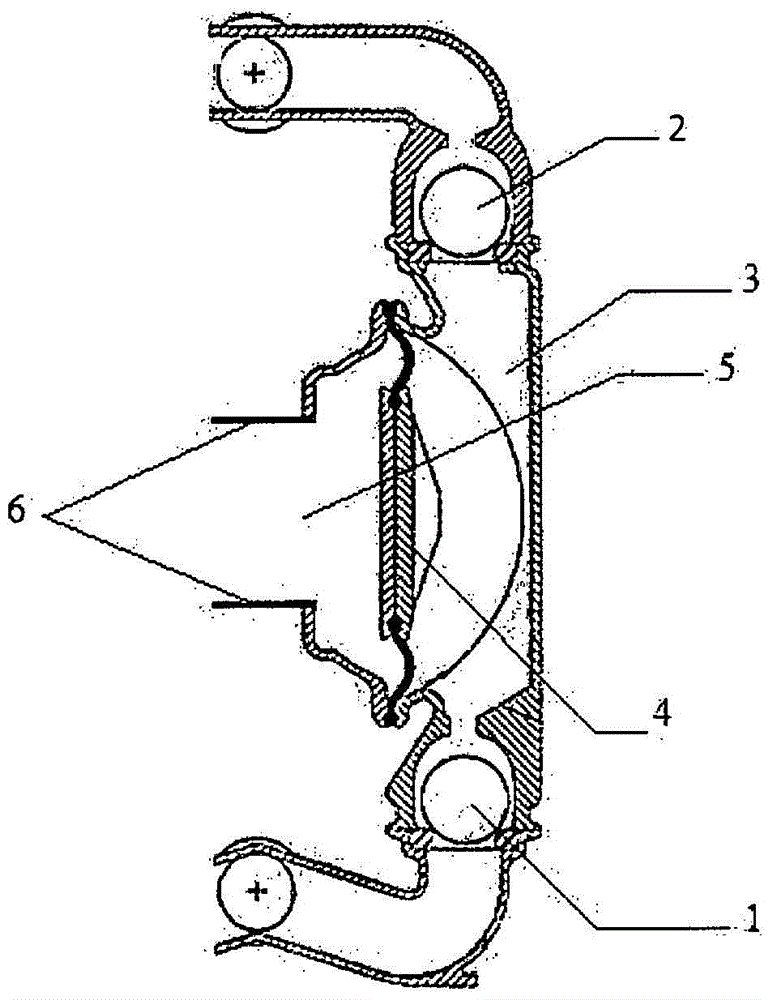

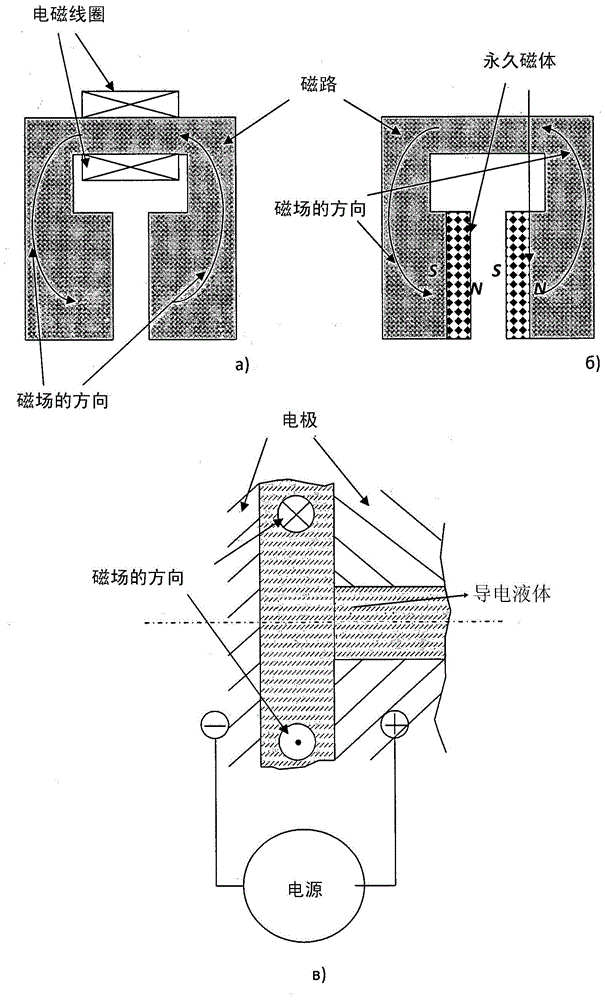

[0020] Example 1. The drive magnetic system generates a permanent magnetic field. In this case there are permanent magnets or electromagnetic coils, and a magnetic core with poles perpendicular to the electrodes 6 of the driven chamber 5 . The solenoid coils are powered from a DC power source. When using a permanent magnetic field, the reciprocating motion of the conductive liquid and of the driven membrane 4 is thus provided by an alternating current.

example 2

[0021] Example 2. The power supply is a DC power supply, which supplies DC power between the electrodes 6 of the driven chamber 5 . When direct current is used, the reciprocating motion of the driven diaphragm 4 is provided by the alternation of the magnetic field. The driving magnetic system comprises an electromagnetic coil and a magnetic core with magnetic poles perpendicular to the electrodes 6 of the driven chamber 5 . The electromagnetic coil is powered from its own AC power source. The alternating current in the electromagnetic coil provides an alternating field in the driven chamber 5 and thus the reciprocating motion of the conductive liquid and the driven membrane 4 .

example 3

[0022] Example 3. The power source is an AC power source, and an AC current is supplied between the electrodes 6 of the driven chamber 5 . The driving magnetic system comprises an electromagnetic coil and a magnetic core with magnetic poles perpendicular to the electrodes 6 of the driven chamber 5 . The electromagnetic coil is powered from its own AC power source. The combination of alternating current and alternating magnetic field makes the movement of the conductive liquid and the driven membrane 4 obey different laws, which can be used for special purposes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com