Pulse cloth bag type dust removal equipment used on smelting furnace

A technology of pulse cloth bag and dust removal equipment, which is applied in the direction of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of air pollution and low purification quality, and achieve the effect of removing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention

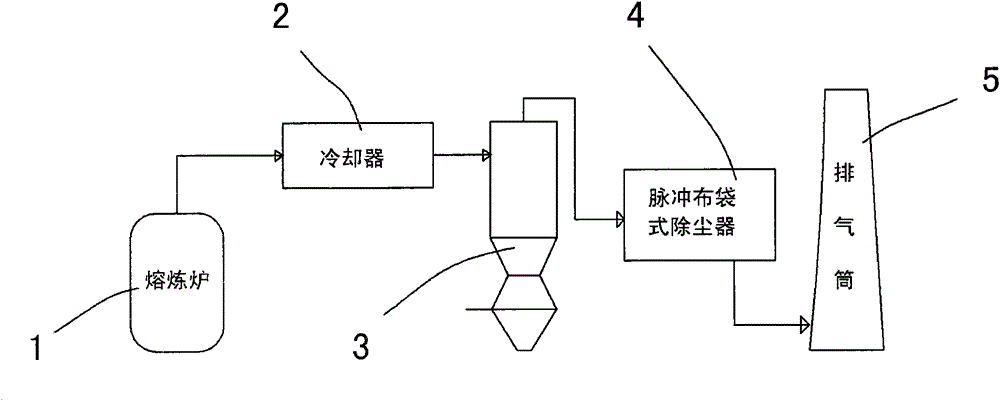

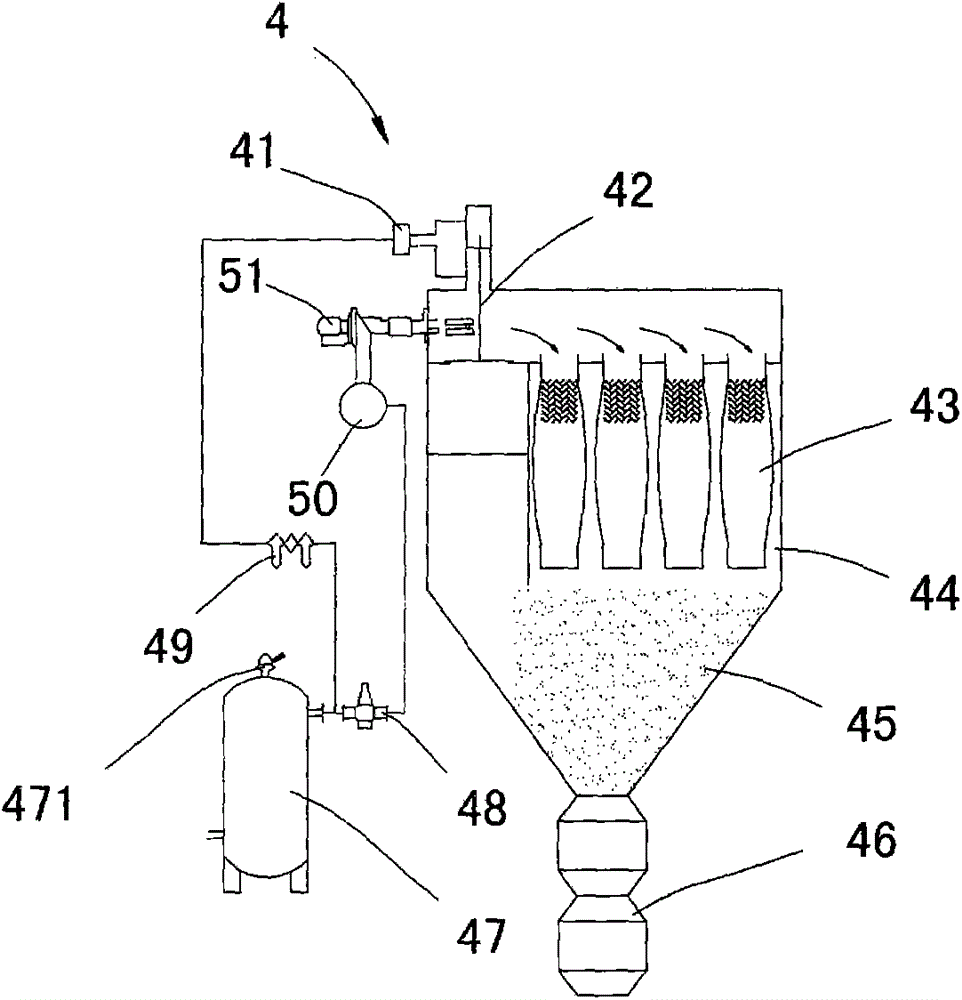

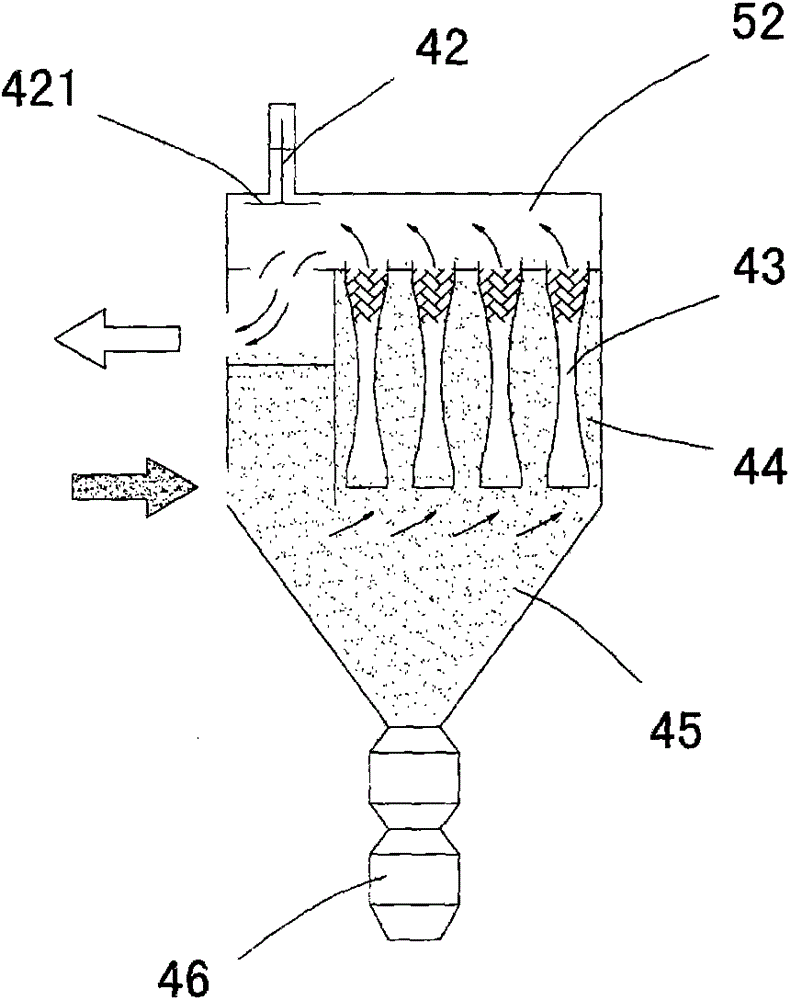

[0024] Such as Figures 1 to 6 Shown is the embodiment of the pulse bag type dedusting equipment used on a kind of smelting furnace of the present invention, it comprises a cooler 2 that communicates with 1 outlet of smelting furnace, the outlet of cooler 2 communicates with the inlet of cyclone settling barrel 3 , the outlet of the cyclone settling barrel 3 is connected with the inlet of the pulse bag filter 4, and the outlet of the pulse bag filter 4 is connected with the inlet of the exhaust pipe 5;

[0025] The cyclone settling bucket 3 is composed of a settling bucket body 31 and a high-speed exhaust fan 32. The inner wall of the settling bucket body 31 is formed with a spiral guide groove 33, and the top of the settling bucket body 31 is provided with a The insertion pipe 34 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com