Device for cleaning aluminum bonded on hub mold

A hub mold, aluminum sticking technology, applied in cleaning methods and utensils, liquid cleaning methods, chemical instruments and methods, etc., can solve the problems of damage to the cleaning pool, cleaning liquid evaporation, cleaning liquid concentration instability, etc., to improve The overall strength, ensuring the height of the liquid level, and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

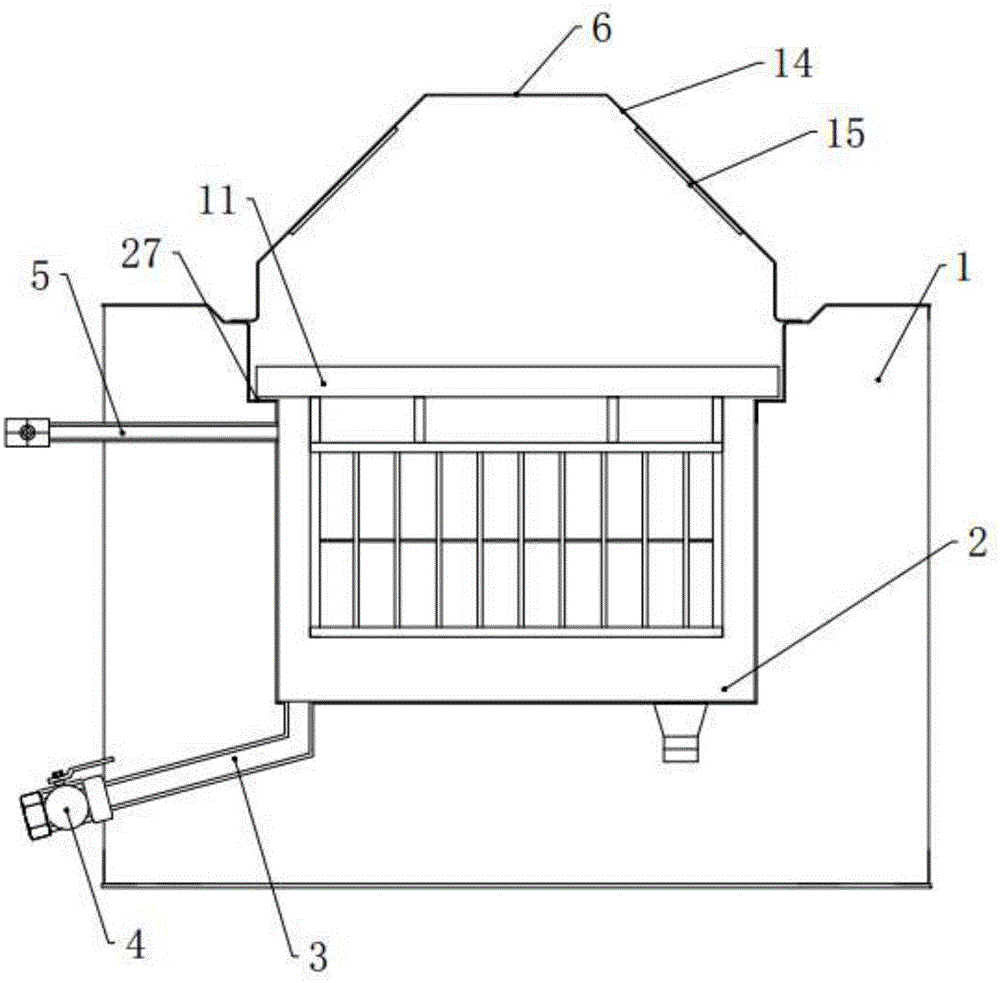

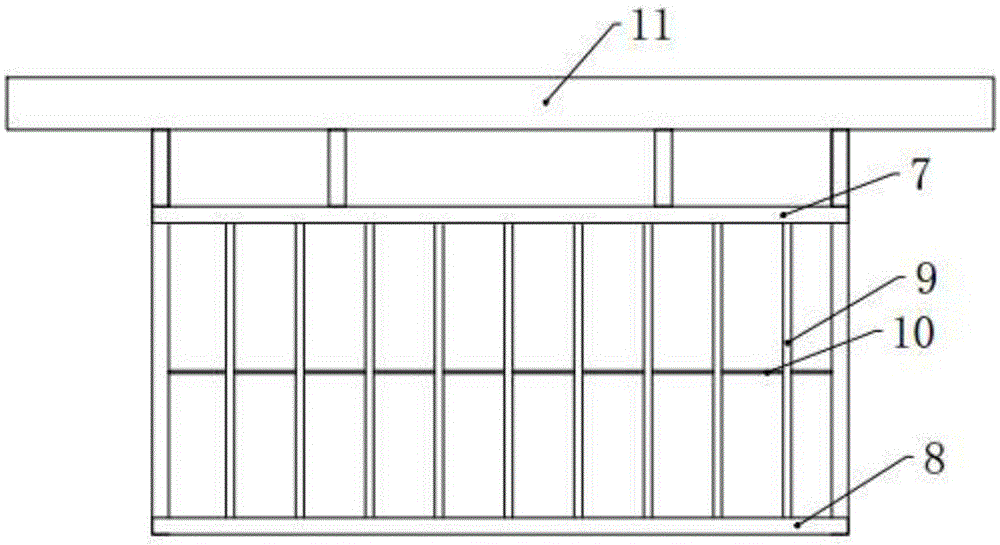

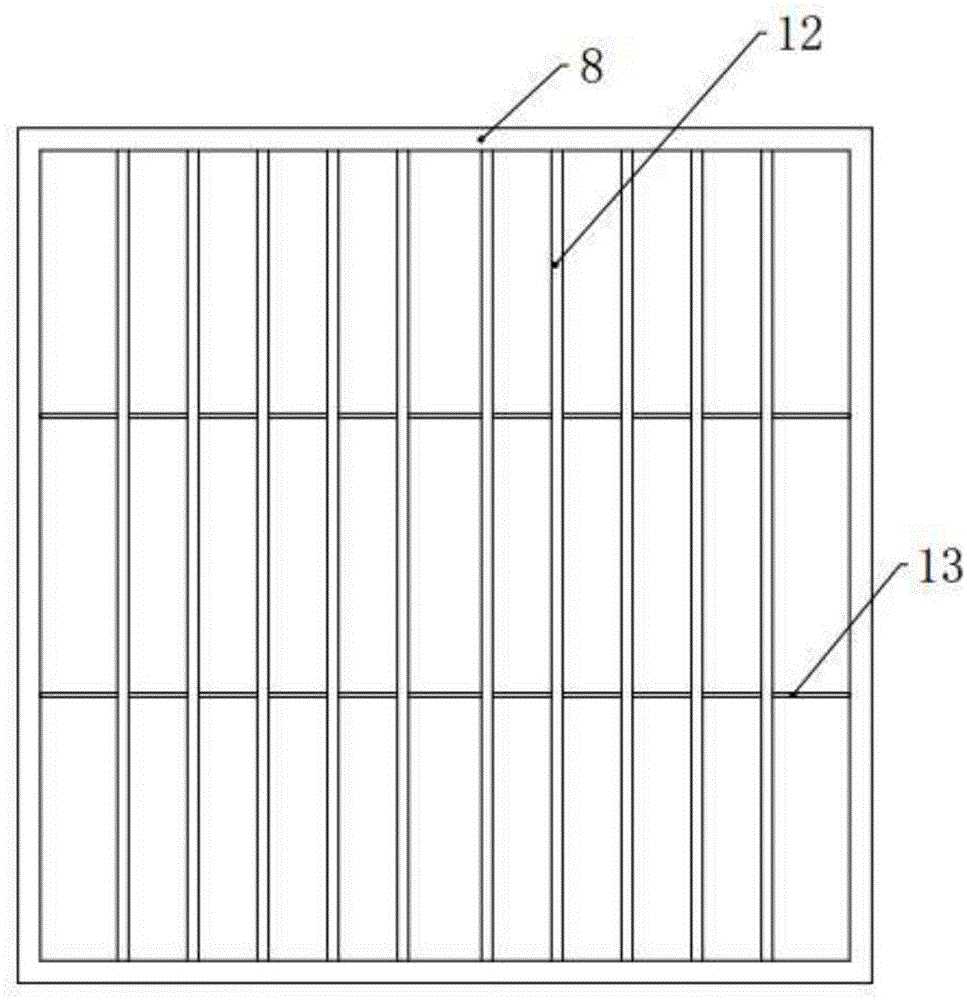

[0017] The device for cleaning the sticky aluminum of the hub mold includes a frame 1 and a cleaning pool 2 located in the frame 1, and it also includes a backflow cover 6 and a protection mechanism. The frame 1 is provided with an ultrasonic transmitter located below the cleaning pool 2, so The protective mechanism includes an upper frame 7 and a lower frame 8, a vertical protective bar 9 and a horizontal protective bar 10 are arranged between the upper frame 7 and the lower frame 8, and the horizontal protective bar 10 and the vertical protective bar 9 are cross-fixed , the upper frame 7 is provided with a support frame 11, the frame 1 is provided with a step groove 27 for the installation of the support frame 11, and the lower frame 8 is provided with a first protective bar 12 and a second cross fixed Two protective rods 13 , the return cover 6 is installed on the frame 1 , the return cover 6 is located above the cleaning tank 2 , and the return cover 6 is provided with an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com