Method for improving uniformity of composite material manufactured by friction stir processing through adding polytetrafluoroethylene

A polytetrafluoroethylene and friction stir technology, used in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problem of enhancing the inhomogeneity of metal matrix composite materials, and achieve the effect of increasing the amount of formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

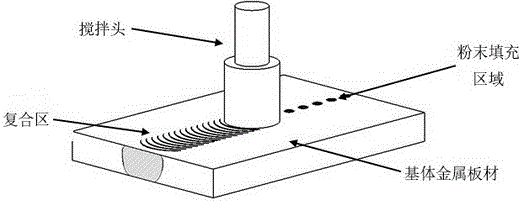

[0032] Specific implementation mode two: combination figure 1 Describe this embodiment, the content of PTFE among the step one of this embodiment is 1%, the diameter of hole is 3mm, interval 4mm, depth of blind hole 4mm, stirring head rotation speed 950 r / min, welding speed 30mm / min, stirring The head inclination angle is 2°, and the processing passes are 5 times.

specific Embodiment approach 3

[0033] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the content of PTFE in the first step of this embodiment is 3%, and the other steps are the same as in the second embodiment.

specific Embodiment approach 4

[0034] Specific implementation mode four: combination figure 1 To illustrate this embodiment, the content of PTFE in the first step of this embodiment is 5%, and the other steps are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com