Welding flash flatting device for cowry type grab bucket

A leveling and grabbing technology, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems that affect the appearance of the grabbing bucket, not easy to smooth the welding bump, and the high temperature of the welding joint, so as to achieve compact structure and increase Beautiful appearance and good movement adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

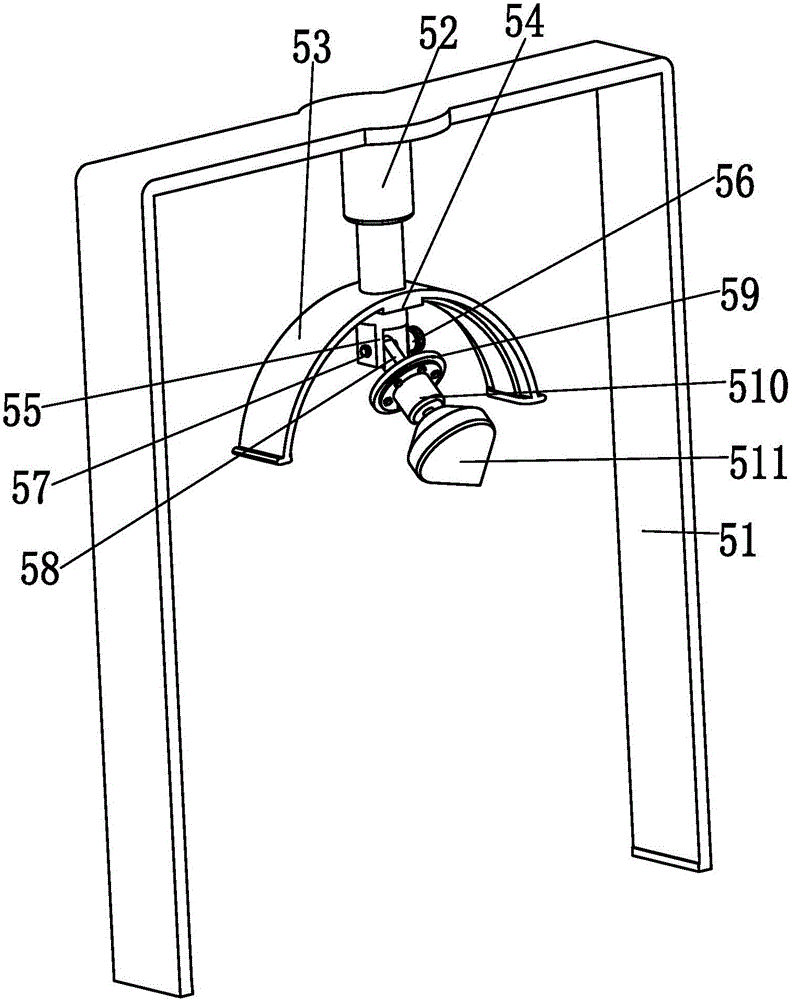

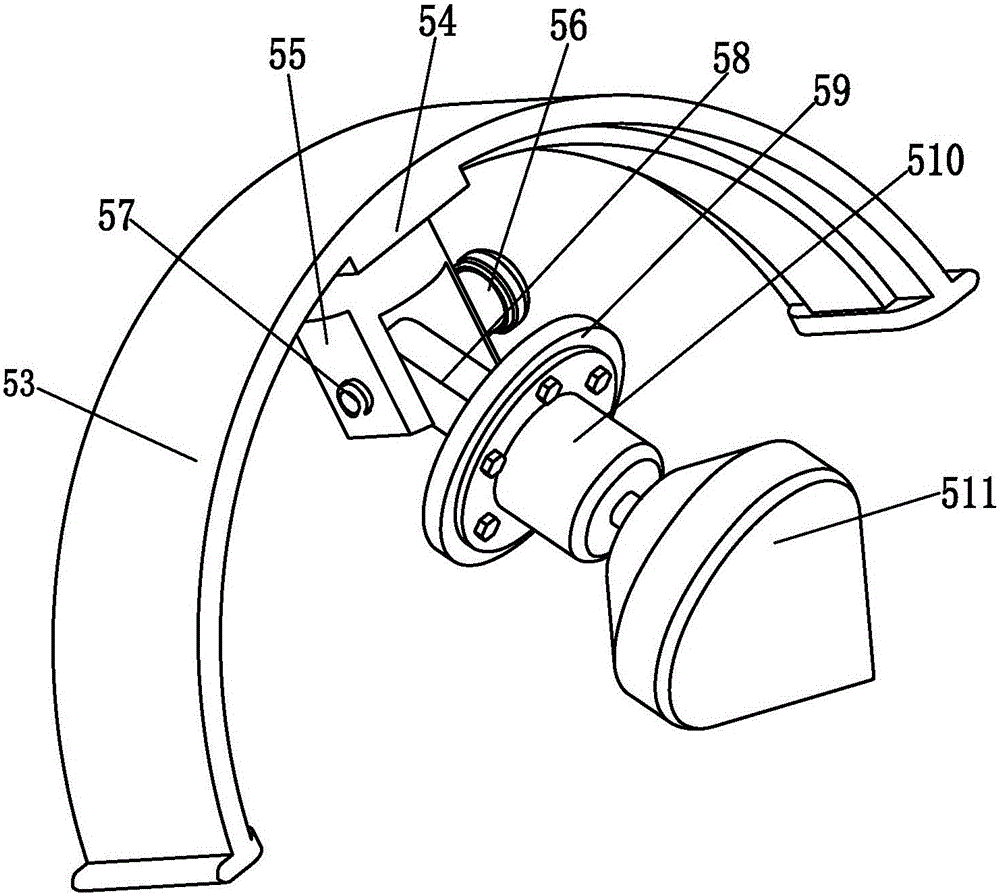

[0011] Such as figure 1 As shown, a clamshell type grab welder leveling device includes No. 2 gantry bracket 51, No. 2 electric push rod 52, No. 2 electric slide rail 53, leveling slider 54, rotating ear seat 55, rotating motor 56, and rotating shaft 57, connecting rod 58, fixed seat 59, leveling motor 510 and leveling grinding head 511; the bottom of No. 2 electric push rod 52 is fixed at the middle position of No. 2 gantry bracket 51, and the top of No. 2 electric push rod 52 is connected with the The No. 2 electric slide rail 53 is connected, the No. 2 electric slide rail 53 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com