Tool for rapidly and safely dismounting sintered metal ring blowing head

A sintered metal, safe technology, used in manufacturing tools, hand-held tools, etc., can solve the problems of de-soldering of flange and ring blowing head, difficult to disassemble, unable to meet process requirements, etc., to meet safety and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

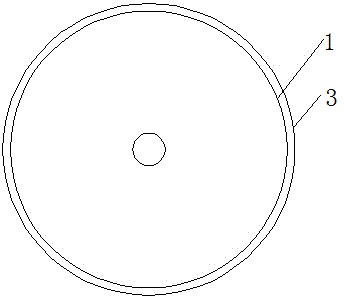

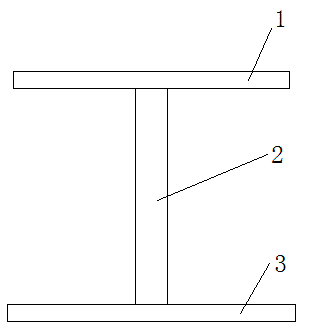

[0016] Such as figure 1 , 2 As shown, a tool for quickly and safely removing a sintered metal ring blowing head includes a circular top plate 1, a support rod 2, and a circular bottom plate 3. The circular top plate 1 is connected with the circular bottom plate 3 through support rods 2 . One end of the support rod 2 is welded to a circular top plate, and the other end is welded to a circular bottom plate.

[0017] The diameter of the circular top plate 1 is 248mm. The diameter of the top plate is smaller than the outer diameter of the ring blowing head and the inner diameter of the shaft, so that the top plate can be conveniently pressed against the lower edge of the ring blowing head.

[0018] The height of the support rod 2 is 190mm. The height of the support rod satisfies the ejection stroke of the operating ring blowing head, ensuring that the ring blowing head will not be completely pushed out of the tunnel and cause a skewed fall.

[0019] The diameter of the circul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com