Aluminum profile double-fan vacuum wooden transfer furnace

A technology of wood grain transfer printing and aluminum profiles, applied in transfer printing, rotary printing machines, printing, etc., can solve the problems of uneven coating thickness on the surface of profiles, high manufacturing costs, reduced production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific embodiment:

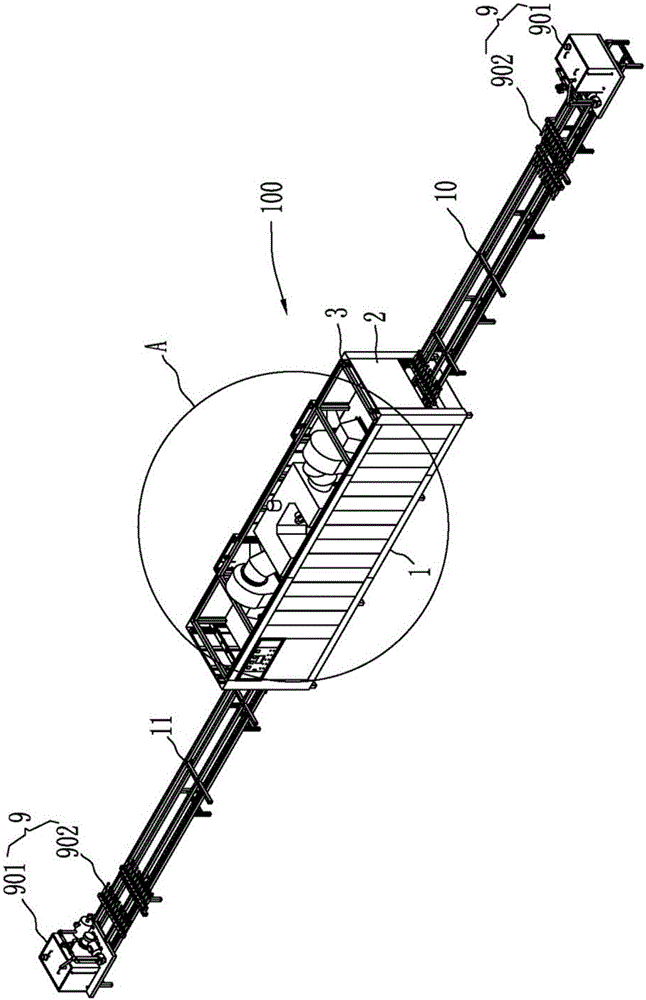

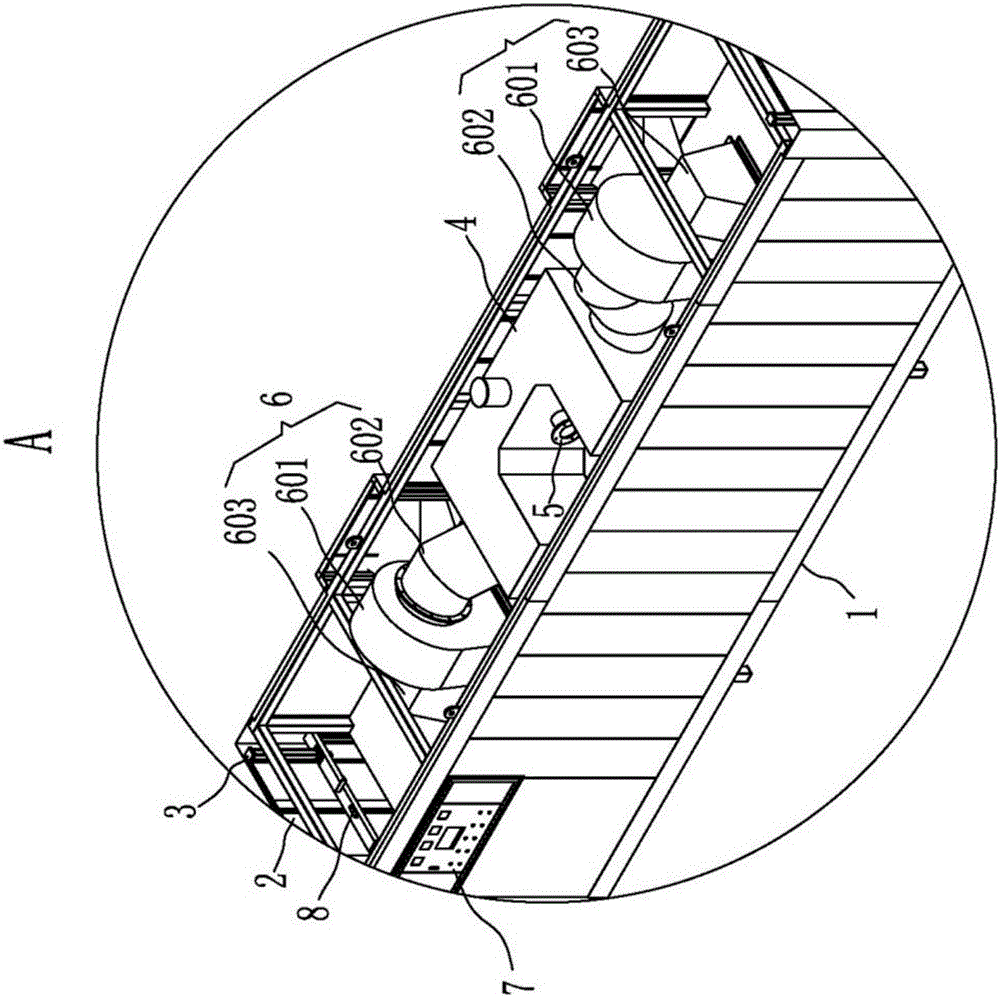

[0012] See attached figure 1 and 2 As shown, an aluminum profile double fan vacuum wood grain transfer furnace 100 described in this embodiment includes a wood grain transfer furnace body 1, a pair of furnace doors 2 located at both ends of the wood grain transfer furnace body 1, A pair of driving devices 3 respectively used to drive a pair of furnace door 2 to close and open, a combustion liner 4 arranged on the top of the above-mentioned wood grain transfer furnace body 1, and a combustion liner 4 for providing heat to the combustion liner 4 Burner 5, a pair of circulating air blowing components 6 respectively connected to both sides of the combustion liner 4 for providing hot air to the aluminum profile in the inner cavity of the wood grain transfer furnace body 1, located on both sides of the wood grain transfer furnace body 1 A pair of vacuum transfer systems 9 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com