Fixing structure of electric apparatus to vehicle

A technology for electrical equipment and fixed structures, which is applied to electrical equipment shells/cabinets/drawers, electric vehicles, vehicle parts, etc. It can solve the problems of shell damage and the shell is not so rigid, and achieve the effect of improving collision safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

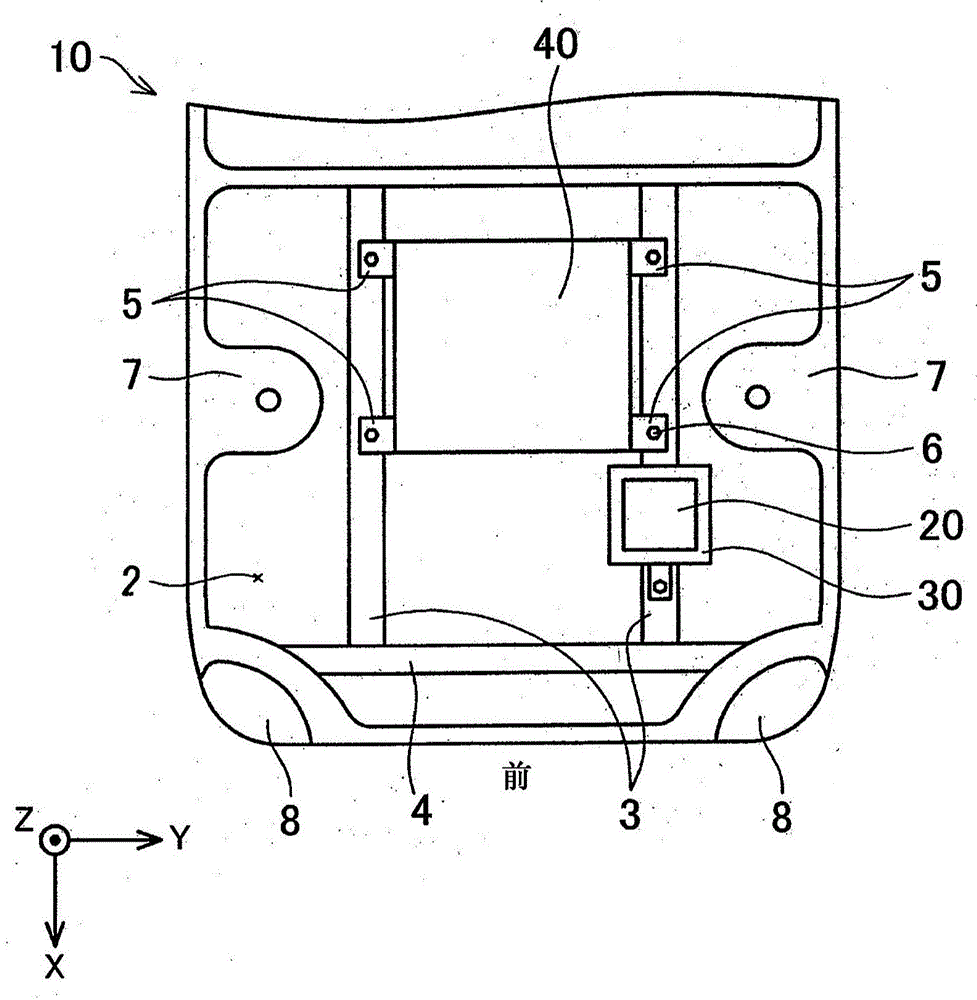

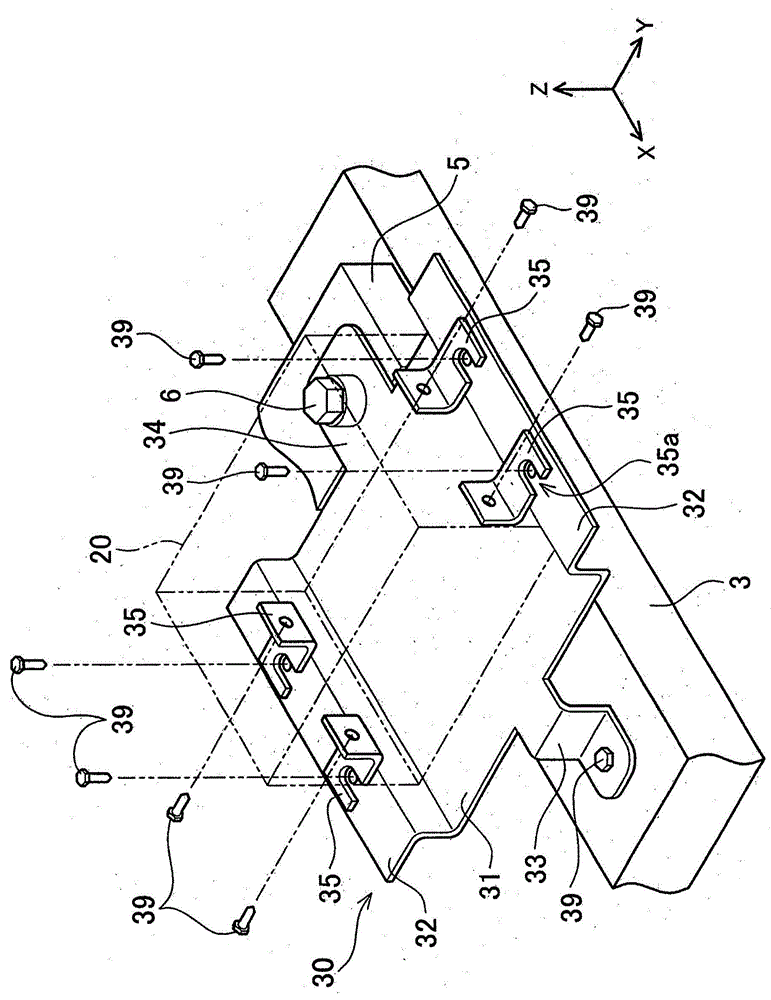

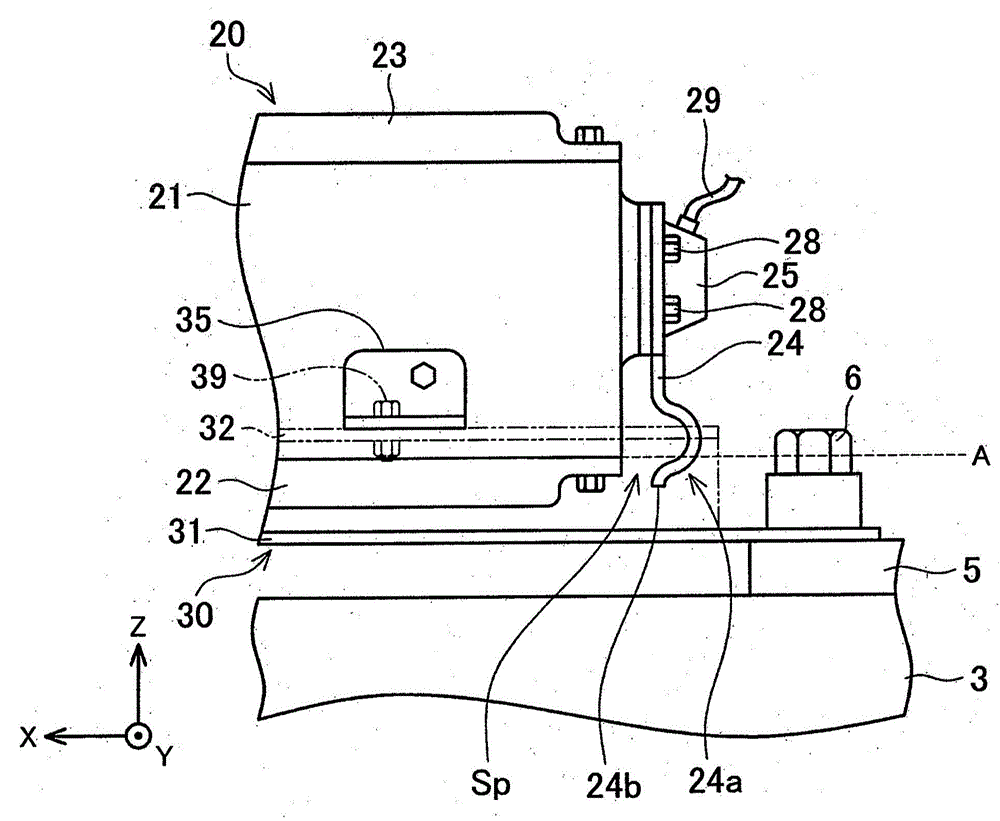

[0021] This section describes a fixing structure of an inverter of an electrically driven vehicle as a typical example of the fixing structure described in the present invention. Important devices such as an inverter, an engine (motor), and a gearbox are fixed to a frame for supporting the body. Specifically, in many vehicles, two frames extending in the front-rear direction are provided under a compartment (an engine compartment at the front of the vehicle), and an inverter and a motor are fixed to the frames. The two frames extending in the front-to-back direction are called stringers. Where some devices are secured to longitudinal beams extending in the fore-and-aft direction, the devices are aligned in the fore-and-aft direction. In a typical example, the engine (motor) is fixed between two side beams, and the inverter is fixed to one of the side beams in the front of the engine. Specifically, the engine (motor) is large, and further, becomes a vibration source. Therefo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com